Ketley Brick passes rigorous freeze-thaw testing with flying colours

Ketley Brick has eased through rigorous industry freeze-thaw tests for the performance of its textured and “hit and miss” brickwork in severe exposure conditions.

The company, which produces F2 Frost resistant ‘Class A’ Staffordshire Engineering bricks, which are renown for their high compressive strength and low water absorption, has set a new performance benchmark for this brickwork, opening fresh design possibilities for architects working with decorative brickwork facades.

The test procedure, conducted by independent testing house and UKAS accredited Lucideon Ltd., required the bricks to experience nothing more than minor cracks when tested at 100 freeze-thaw cycles on all five exposed faces; Ketley bricks encountered no damage at all.

Furthermore, the test panel, which comprised bricks of varying degrees of projection, demonstrated Ketley’s textured and “hit and miss” brickwork could withstand freeze-thaw conditions when projected at 50mm, which is far beyond the standard 30mm projection of bricks tested in the past.

F2 certification is not enough

Recent independent industry tests have shown that F2 certification, the highest frost resistance classification for facing bricks in flush finished brickwork, does not necessarily indicate the same bricks can withstand more severe omnidirectional freeze-thawing conditions in exposed applications.

In fact, in earlier textured brickwork tests, many F2 facing bricks experienced failures, which could potentially result in degradation of the bricks when projecting.

The freeze-thaw experienced by textured and “hit and miss” brickwork is severer than that experienced by conventional flush brickwork, which means bricks with very low water absorption properties are required.

The need to give confidence to specifiers

Given the severe conditions that textured and “hit and miss” brickwork have to withstand, Ketley Brick thinks it is important to offer architects bespoke performance data as a guidance for their specification.

Alex Patrick-Smith, Managing Director of Ketley Brick said: “We are confident that our ‘Class A’ bricks have the right characteristics to be suitable for exposed brickwork as they have been successfully used in many such situations.

“As F2 certification does not guarantee performance in exposed applications, we are pleased to be able to offer bespoke laboratory test evidence specifically for textured and “hit and miss” brickwork to help give architects, builders and contractors complete confidence in their brick specification.”

Architectural examples

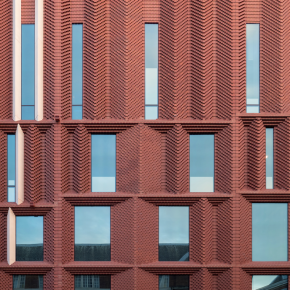

Recently, there has been a renaissance in the use of textured and “hit and miss” brickwork on prestigious buildings, with architects designing more innovative and aesthetically striking facades.

Victoria Gate in Leeds (pictured throughout) is an incredible example of the creative and innovative use of projecting brickwork on a prestigious award-winning project.

Designed by ACME, substantial time went into researching the physical characteristics of bricks before Ketley’s Staffordshire Red was chosen.

Friedrich Ludewig from ACME said: “It has taken us a while to find a brick that looks good and can deal with exposure on all surfaces.

“We know of several complex brick facades that had insurance claims and needed major work, as water ingress led to spalling and detachment. Ketley Bricks made a custom extrusion with high crushing strength and very low water absorption for frost resistance.

“The Engineering Brick range is strong enough to be used as a paver so we were confident this was the right brick for this prestigious project.”

Ketley’s ‘Class A’ engineering bricks are highly durable and their precise form, natural clay colour and range of matching specials, mean architects can create imaginative designs and decorative details, safe in the knowledge they are fit for purpose in all manner of situations, including severely exposed brickwork.

Telephone: 01384 78361

Fax: 01384 74553

Email : sales@ketley-brick.co.uk

Visit Supplier's page

Latest news

29th April 2025

Senior pledges to ‘bee’ part of the solution with new biodiversity initiative

Senior Architectural Systems has installed its first on-site beehive, marking another step forward in its commitment to sustainability and biodiversity.

Posted in Articles, Building Industry News, Building Products & Structures, Building Services, Curtain Walling, Doors, Glass, Glazing, Innovations & New Products, news, Restoration & Refurbishment, Retrofit & Renovation, Sustainability & Energy Efficiency, Walls, Windows

29th April 2025

West Fraser range delivering key benefits for South-East carpentry company

An experienced carpenter and building site manager who has recently set up his own company is using high performance panel products from the West Fraser range.

Posted in Articles, Building Industry News, Building Products & Structures, Building Systems, Case Studies, Garden, Restoration & Refurbishment, Retrofit & Renovation, Sustainability & Energy Efficiency, Timber Buildings and Timber Products

29th April 2025

CPD Courses Available Online From Ecological Building Systems

Ecological Building Systems, a leading supplier of natural building products for sustainable construction, has revealed its comprehensive CPD programme for the year ahead.

Posted in Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Continuing Professional Development (CPD's), Information Technology, Innovations & New Products, Insulation, Restoration & Refurbishment, Retrofit & Renovation, Seminars, Sustainability & Energy Efficiency, Training, Walls, Waste Management & Recycling

29th April 2025

WindowBASE launches new prospect databases at FIT Show

Visit WindowBASE at the FIT Show to see first-hand how it helps companies find new customers – the company is launching an easy-to-use, intuitive platform on Stand G16 at the NEC Birmingham from 29th April – 1st May.

Posted in Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Doors, Exhibitions and Conferences, Glass, Glazing, Information Technology, Innovations & New Products, Posts, Publications, Research & Materials Testing, Restoration & Refurbishment, Retrofit & Renovation, Windows

Sign up:

Sign up: