Sound solution to dramatic facade ventilation with Gilberts

Gilberts is cutting to the chase with its latest evolution of its acoustic, fixed and screening louvres.

The company’s range has been extended and modernised to enable architects to balance a building’s aural and visual impact.

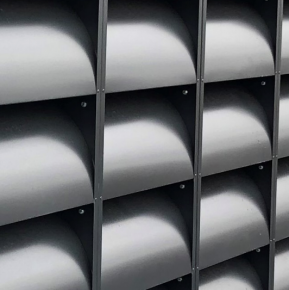

New to the mix is a choice of continuous and curved blades, complimenting the company’s established linear versions whilst offering the same sound reduction capability.

The arcing blades bring the number of blade profile: acoustic attenuation options now available as standard to 12, either in supply, or supply & fit packages.

Further adding to the ‘sound and vision’ dimension, all Gilberts’ louvres can be PPC, PVF and PVF2 powder coated to any RAL colour, with the possibility of anodised in some instances, further expanding the louvres’ potential to form an integral part of the building’s aesthetic features.

Engineered as standard from galvanised steel, the louvres can deliver sound transmission loss of up to 33dB, depending on specification, balanced against appropriate free airflow area to allow adequate ventilation of any plant behind.

Louvre banks interface with the exterior building fabric via steelwork frames, cladding or direct to the brickwork.

Assemblies are produced as standard in sizes 300 x 300 to 1500 x 2000. Using a modular approach on site, louvre screens as long and high as required, even with contouring and graduations, can be designed and fabricated as required.

The entire range of Gilberts’ acoustic louvres is BSRIA (Building Services Research and Information Association) validated.

The acoustic louvre range sits alongside Gilberts’ established ranges of standard and high performance weather louvres.

Contact:

Gilberts of Blackpool,

Gilair Works,

Clifton Road,

Blackpool,

FY4 40T

Phone: 01253 766911

Fax: 01253 767941

Visit Gilberts of Blackpool's website

Visit Supplier's page

Latest news

17th April 2025

Nuaire shares expertise at Specifi Mechanical Services events in 2025

Indoor air quality and ventilation manufacturing specialist Nuaire is pleased to be exhibiting at the Specifi Mechanical Services events once again in 2025.

Posted in Air Conditioning, Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Exhibitions and Conferences, Facility Management & Building Services, Heating, Ventilation and Air Conditioning - HVAC, Restoration & Refurbishment, Retrofit & Renovation

15th April 2025

West Fraser: CaberDek earns top marks from Home Counties carpentry specialist

A specialist carpentry sub-contractor covering housing sites across a large swathe of the Home Counties has come to value CaberDek from the West Fraser range for a variety of reasons: not least because the high quality panel product doesn’t destroy his operatives’ electric saws!

Posted in Articles, Building Industry News, Building Products & Structures, Building Systems, Case Studies, Restoration & Refurbishment, Retrofit & Renovation, Roofs, Timber Buildings and Timber Products, Wooden products

15th April 2025

GEZE: The Role of Access Control Systems in Enhancing Building Safety

Jane Elvins, Specification and Business Development Manager at GEZE UK, delves into the role of access control systems in enhancing building safety…

Posted in Access Control & Door Entry Systems, Architectural Ironmongery, Articles, Building Industry News, Building Products & Structures, Building Services, Doors, Facility Management & Building Services, Health & Safety, Restoration & Refurbishment, Retrofit & Renovation, Security and Fire Protection

11th April 2025

Don’t Do a Dave! It’s Time to Lock FIT Show 2025 in Your Calendar!

It’s that time again – FIT Show is back! You could be forgiven for thinking there won’t be much new to see when FIT Show returns to the NEC from 29 April – 1 May. Wrong!

Posted in Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Continuing Professional Development (CPD's), Exhibitions and Conferences, Information Technology, Innovations & New Products, Restoration & Refurbishment, Retrofit & Renovation, Seminars, Training

Sign up:

Sign up: