Freefoam Building Products – Heroes of Zero

As many manufacturing plants strive towards operating in a more sustainable way to help reduce waste and manage valuable resources, Freefoam Building Products announce a significant milestone on its journey.

Working with waste and energy partner BIFFA, Freefoam send no site waste to landfill.

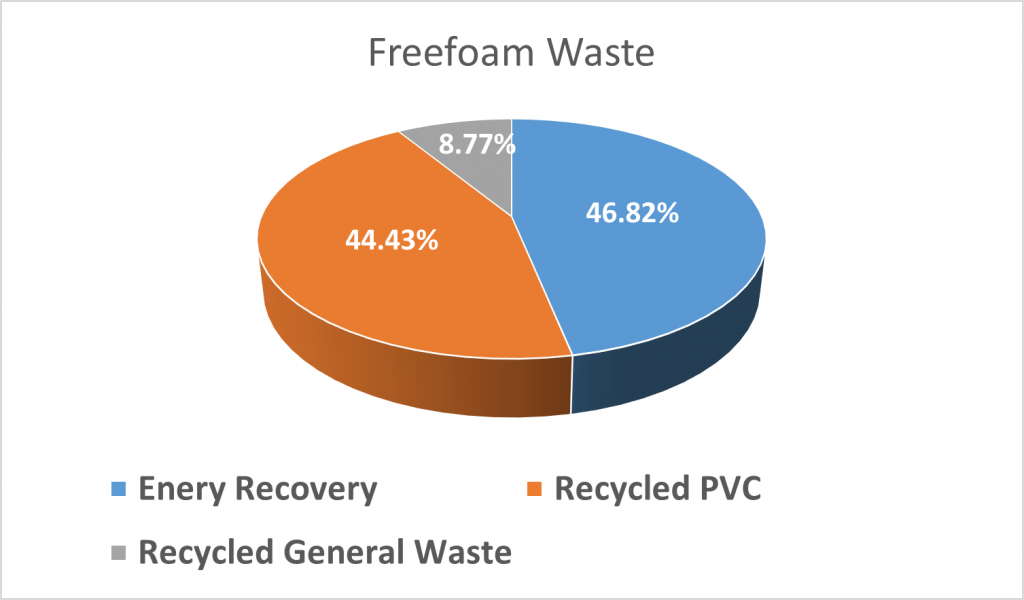

Production and site waste is processed in three ways

In the year to date, 44.43% of the company’s general waste was foam and rigid plastic. This is collected by its waste partner, who process it in to shredded PVC recyclate format.

This material is a valuable commodity and can be used to manufacture many other products. The remaining 8.77% of packaging and cardboard is also sent for recycling.

Commercial waste that is not recyclable, goes to Energy Recovery. It is also collected and transported to a nearby Energy Recovery Facility. Here, it is processed and turned in to energy, which is subsequently sold back to the National Grid.

Energy recovery is a technology that sees non-recyclable waste burned at high temperatures under carefully controlled conditions. The process is extremely efficient, robust and safe, with emissions from the process treated to meet stringent European guidelines.

So what happens to the energy once generated? Taking one month as an example the energy provided by Freefoam waste could have powered a 400 watt fridge freezer for 354 weeks, or 6.8 years or a 1500 watt dishwasher for 118 weeks, or 2.2 years.

Herbert Livingstone, Quality, Safety, Health & Environmental Manager (QSHE), comments: “We are very proud to be operating our plant in such a sustainable way. We have worked hard to separate and manage waste on site so that we don’t need to send any to landfill.

“This work is just a small part of a much wider programme to ultimately deliver a circular business model and help towards the UK’s target to become a net-zero economy.”

Freefoam recently released a new case study featuring Fortex embossed Double Shiplap PVC cladding on four new homes in Stourbridge. Click here for more details.

Contact:

Freefoam Building Products,

77-83 St James Mill Road,

Northampton,

NN5 5JP

United Kingdom

Tel: 01604 591110

Visit Supplier's page

Latest news

28th March 2025

Ideal Heating Commercial announces 10-year warranty on Evomax 2 boiler

Evomax 2, the UK’s number one selling commercial wall-mounted boiler from Ideal Heating Commercial, is now available with a 10-year warranty.

Posted in Articles, Building Industry News, Building Products & Structures, Building Regulations & Accreditations, Building Services, Facility Management & Building Services, Heating Systems, Controls and Management, Heating, Ventilation and Air Conditioning - HVAC, Innovations & New Products, Pipes, Pipes & Fittings, Plumbing, Retrofit & Renovation, Sustainability & Energy Efficiency, Videos

28th March 2025

FLIR Si1-LD Acoustic Imaging Camera for Compressed Air Leak Detection

FLIR, a Teledyne Technologies company, introduces the Si1-LD, an industrial acoustic imaging camera that brings faster and more accurate compressed air leak detection to those operating on a modest condition monitoring budget.

Posted in Acoustics, Noise & Vibration Control, Articles, Building Industry News, Building Products & Structures, Building Services, Facility Management & Building Services, Information Technology, Innovations & New Products, Retrofit & Renovation, Sustainability & Energy Efficiency, Thermal Imaging and Monitors

28th March 2025

LIFTEX 2025 Seminar programme announced

Registration has opened for LIFTEX 2025. Now in its 37th year, LIFTEX 2025 is the UK’s only dedicated exhibition for the lift, escalator and access industry and takes place only once every three years.

Posted in Access Control & Door Entry Systems, Accessibility, Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Regulations & Accreditations, Building Services, Exhibitions and Conferences, Facility Management & Building Services, Health & Safety, Retrofit & Renovation, Security and Fire Protection, Seminars

28th March 2025

MCRMA welcomes ArcelorMittal UK to membership

A UK division of the global steelmaking business ArcelorMittal has become the latest new member of the MCRMA, the industry association representing the metal building envelope sector.

Posted in Articles, Building Associations & Institutes, Building Industry News, Building Products & Structures, Building Systems, Cladding, Facades, Posts, Restoration & Refurbishment, Retrofit & Renovation, Roofs, Steel and Structural Frames, Walls

Sign up:

Sign up: