Hush meeting acoustic standards with domestic screeded floors

With minimum acoustic standards applying to all ‘connected’ domestic properties under the Building Regulations of all four UK nations, falling short of the requirements when dealing with screeded concrete/masonry floors could result in costly remedial work if it fails to get building control sign-off, as Hush Acoustics explains…

Separating floors in all types of apartments, regardless of their type of construction, have to be built to a performance standard that minimises airborne and impact sound transmission between properties. These apply to new build and conversion projects for which different levels of sound transmission may need to be met.

What the Building Regs demand

In England and Wales under Approved Document E, the minimum level of airborne sound resistance for dividing floors between homes is 45dB (decibels) in new builds and 43dB in conversion projects. The requirement for impact sound, such as footsteps or dropped objects, stipulates a maximum sound transmittance level of 62dB in new builds and 64dB for conversion projects.

In Northern Ireland the figures are the same, but in Scotland the minimum for airborne sound is 56db and a maximum of 56db for impact sound. Slightly different requirements apply to ‘traditional buildings’ built pre-1919.

There are no directly equivalent standards for non-domestic buildings, but certain applications do require measures to be taken to address sound transmission and acoustic comfort, such as in schools and hospitals. But it is also good practice to ensure separating walls and floors are also acoustically insulated to a high standard in commercial or public sector applications where noise between properties or rooms could be a nuisance – hotels and some offices, for example.

You can read more about what the Building Regulations require using these links:

- England & Wales – Approved Document E

- Scotland – Building Standards technical handbook 2017 Section 5: Noise

- Northern Ireland – Technical Booklet G

Why does a screeded floor need acoustic insulation?

The density of concrete and masonry means it is a relatively effective reducer of airborne sound transmission, but impact sounds can still get through. The solution is to add a resilient layer across the floor surface to absorb the sound waves that transmits through the floor covering, such as tiles and wooden floors, then the concrete.

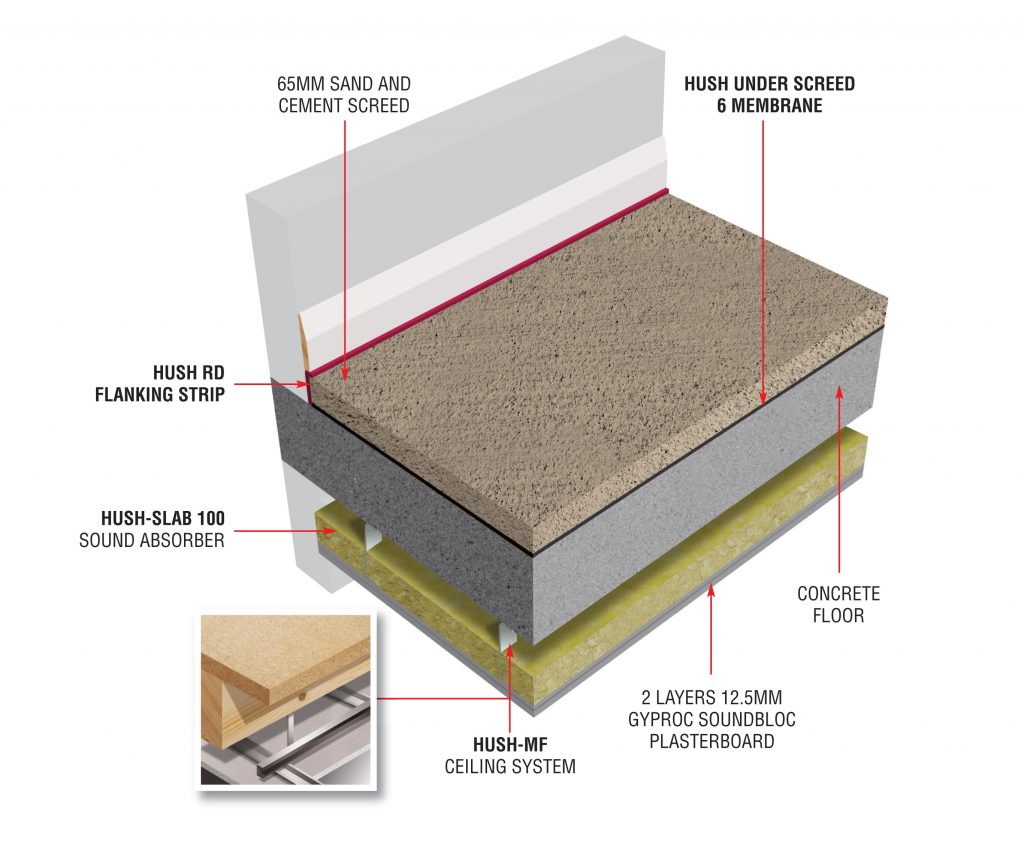

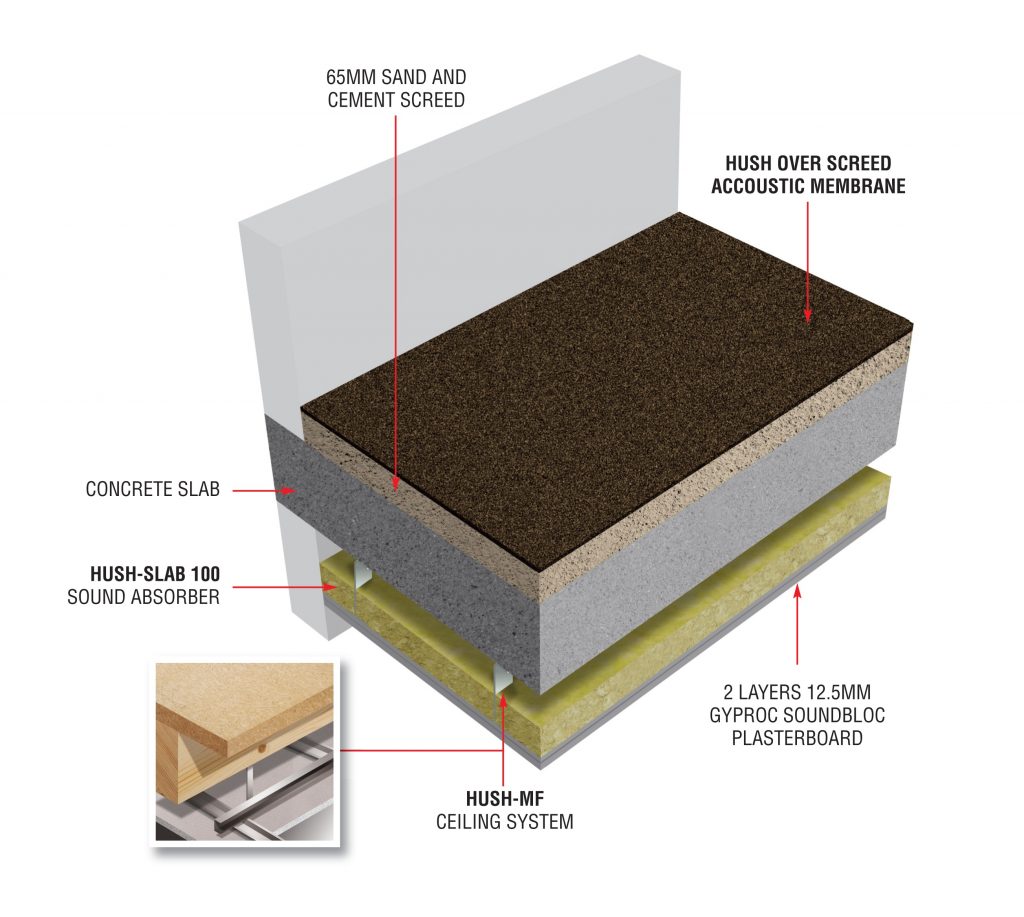

Hush Acoustics recommends using a dense, rubber based membrane within the floor make-up – Hush Under Screed or Hush Over Screed. These are designed to combine minimum build height with permanent resilience, in a material composition that is easy to Install and remains continually elastic over its lifetime. And they are manufactured using recycled materials.

Under or over?

There are two ways in which you can add a layer of rubber-based acoustic insulation to a screeded floor under the screed or over. But which is best?

If you are starting from scratch with a new screeded floor, we would recommend installing the Hush Under Screed membrane every time. This is because the floor treatment can then be fully versatile.

This is particularly important in respect of underfloor heating (UFH) which is rapidly growing in popularity and is expected to be even more so as gas boilers are replaced with air source heat pumps. If the acoustic membrane is contained under the screed, installing a UFH system is as easy as it can be.

However, it is not always possible to fit an acoustic membrane under the screed. If you are working on a renovation or conversion project that already has a screeded floor in-situ, it would not make any sense to tear it up simply to install an acoustic membrane! That’s why the Hush Over Screed acoustic membrane was developed.

Hush Over Screed Acoustic Membrane is formed using a fine granulate of recycled rubber with a cork and PU elastomer bonding agent. It comes in roll length/widths of 20m x 1m, and is available in thicknesses of 3mm, 4.5mm or 5mm. once installed, most floor coverings can be applied directly on top, such as ceramic tiles (with suitable anti-cracking membrane and flexible adhesive), sheet vinyl (not pure PVC), laminate, wooden floors, carpet and carpet.

The Hush Under Screed Acoustic Membrane is manufactured from a fine rubber granulate with a high resistance to compressive loads and outstanding elasticity. Thicknesses of 3mm, 5mm, 6mm, 8mm and 10mm are available for the membrane which is designed to be loose laid with no slipping during installation.

Get expert acoustic advice for concrete floor insulation

It is extremely important to get the acoustic insulation right in screeded floors, especially in domestic properties where the minimum requirements of the Building Regulations have to be met. With the range of solutions available from Hush Acoustics, we have the products and systems to help you achieve the required standards and avoid the risk of the finished screed floor failing acoustic testing on completion.

Hush Acoustics have been manufacturing and supplying acoustic insulation products for more than 30 years which means our sound reduction specialists have a wealth of expertise to offer.

Hush Acoustics Ltd

Unit 2, Tinsley Industrial Estate

Shepcote Way

Sheffield

South Yorkshire

S9 1TH

Tel: 0114 551 8685

Fax: 0151 944 1146

Visit Supplier's page

Latest news

21st November 2024

Altro distils style and performance at English Spirit

English Spirit Distillery has used an extensive package of Altro products front and back of house, in their new visitor centre café, shop and viewing area for the working distillery.

Posted in Articles, Bathrooms, Bedrooms & Washrooms, Building Industry News, Building Products & Structures, Building Systems, Case Studies, Floors, Interior Design & Construction, Interiors, Kitchens, Restoration & Refurbishment, Retrofit & Renovation, Timber Buildings and Timber Products, Walls

21st November 2024

Abloy UK creates bespoke locking solution for Secure Information Boxes

Abloy UK has supplied The Safety Letterbox Company Ltd with a bespoke Sentry CL811 Camlock for use in its Secure Information Boxes, assisting life safety and complying with new regulations and legislation for high rise buildings.

Posted in Access Control & Door Entry Systems, Architectural Ironmongery, Articles, Building Industry News, Building Products & Structures, Building Regulations & Accreditations, Building Services, Case Studies, Facility Management & Building Services, Health & Safety, Posts, Restoration & Refurbishment, Retrofit & Renovation, Security and Fire Protection

20th November 2024

CUPA: CUPACLAD enhances hotel aesthetics with a creative natural slate façade

Situated at the northern edge of a newly developed retail park near Bristol, the Abbey Wood Travelodge was conceived as part of the company’s new Budget-Luxe line of hotels – it features CUPACLAD, from CUPA PIZARRAS.

Posted in Articles, Building Industry News, Building Products & Structures, Building Systems, Case Studies, Cladding, Concrete, Cement, Admixtures, Facades, Posts, Restoration & Refurbishment, Retrofit & Renovation, Walls

20th November 2024

Origin launches in-house powder coating facility

Origin’s latest investment is set to redefine industry standards as it launches its own in-house powder coating facility.

Posted in Aluminium Products, Articles, Building Industry News, Building Products & Structures, Building Systems, Doors, Glass, Glazing, Innovations & New Products, Paints, Coatings & Finishes, Restoration & Refurbishment, Retrofit & Renovation, Site Preparation, Windows

Sign up:

Sign up: