Delta Membranes launch new 695 Groundwater Sump Pump Chamber

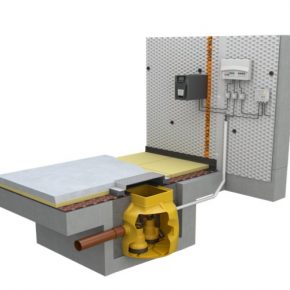

Delta Membrane Systems Limited, an innovator within the waterproofing industry, proudly launches the new 695 Sump Pump Chamber, pushing the boundaries of what’s possible in sump pump applications.

If you are considering a basement drainage system, the Delta basement drainage range is a worthwhile contender. The Delta 695 Sump Pump Chambers are suitable for ground and surface water collection. The new 695 chamber is suitable for all Delta Dual V3, V4 and V6 pump stations.

Advantages of the 695 Sump Pump Chambers

– New unique design

– Finite Element Analysis (FEA)

– Channel locators for ease of installation

– Alternative cable duct height option

– Sealing lip

– Compatible with the Delta V3, V4 and V6 sump pumps

– Able to accommodate varying pumping heights of Delta V sump pump range

– New slim lid able to withstand pedestrian traffic

New unique design

The Delta 695 chamber offers the next level in basement sump chambers. Its compact new size doesn’t compromise of capacity or durability. This specially designed sump chamber has many advantages over previous models. The versatility of the Delta 695 chamber is unmatchable and it’s compatible with all Delta V3, V4 and V6 sump pumps.

Not forgetting the all-important cost savings either. Although the Delta 695 chamber may be smaller in size, it has big benefits, including lower excavation costs, labour costs, waste disposal costs and less requirement for concrete/steel (when housed).

Finite Element Analysis (FEA)

Finite element analysis is the process of replicating the behaviour of a part or assembly (in this case the Delta 695 chamber) under given conditions so that it can be assessed using the finite element method (FEM).

Channel locators for ease of installation

Delta 695 chambers have a distinctive preformed channel position area for ease of installation.

Cable duct height option

Delta understand the need for project specifics, which is why the Delta 695 chambers come with a preformed choice of height for cable duct/vent pipe. This distinctive preformed option allows for simplifying installation.

External Sealing lip

To reduce risk, Delta announce the addition of an external sealing lip to the 695 chambers. This sealing lip will allow installers to apply Delta AKTI-VO 201 (swellable mastic) to the entire external lip locator of chamber. Once the sump chamber is backfilled, this seal will offer a continuous waterproofing approach.

Compatible with the Delta V3, V4 and V6 sump pumps

If you need consistent, reliable performance, the Delta 695 chamber will not disappoint. The Delta 695 chamber is fully compatible with the Delta V3, V4 and V6 submersible pumps. Saving on storage, handling costs and packaging whilst enabling installers to maximise on installation depths – as there is one standard size required for all.

Able to accommodate varying pumping heights of Delta V sump pump range

The Delta 695 chamber has been designed to accommodate all varying pump heights of the Delta V3, V4 and V6 sump pumps. It is common for basements to be lower than mains drainage pipes and sewers serving the structure. Any drainage from a basement or below ground structure will need to be pumped up. The term ‘pumping height lift’ is used to indicate the vertical height the pump is required to pump up.

New slim lid able to withstand pedestrian traffic

Follow-on construction trades, on occasion, can be hazardous to Type C systems, and a certain amount of risk to the waterproofing system is encounterable.

A damaged chamber lid can lead to debris and other construction waste entering the basement drainage system. An inoperable chamber lid can make it impossible to inspect, service or commission the sump pump system. The new Delta 695 chamber not only has a slimmer lid to previous models, but is also able to withstand pedestrian traffic, mitigating any follow-on trade accidents.

Delta Pumps are proud to be manufacturing and fabricating all their sump pump chambers from its new warehouse facilities in a new dedicated Pump Distribution Hub close to its Epping Headquarters. This will enhance the company’s ability to serve its nationwide customer base.

To explore the new range of Delta Pumps, visit Package Pumps and Basement Drainage Systems – Delta Membranes.

Whatever the needs of your project, call Delta on 01992 523 523 or email [email protected].

Delta Membrane Systems,

Delta House,

Merlin Way,

North Weald,

Epping,

Essex,

CM16 6HR

United Kingdom

Visit Delta Membrane Systems' website

Visit Supplier's page

Latest news

21st November 2024

Altro distils style and performance at English Spirit

English Spirit Distillery has used an extensive package of Altro products front and back of house, in their new visitor centre café, shop and viewing area for the working distillery.

Posted in Articles, Bathrooms, Bedrooms & Washrooms, Building Industry News, Building Products & Structures, Building Systems, Case Studies, Floors, Interior Design & Construction, Interiors, Kitchens, Restoration & Refurbishment, Retrofit & Renovation, Timber Buildings and Timber Products, Walls

21st November 2024

Abloy UK creates bespoke locking solution for Secure Information Boxes

Abloy UK has supplied The Safety Letterbox Company Ltd with a bespoke Sentry CL811 Camlock for use in its Secure Information Boxes, assisting life safety and complying with new regulations and legislation for high rise buildings.

Posted in Access Control & Door Entry Systems, Architectural Ironmongery, Articles, Building Industry News, Building Products & Structures, Building Regulations & Accreditations, Building Services, Case Studies, Facility Management & Building Services, Health & Safety, Posts, Restoration & Refurbishment, Retrofit & Renovation, Security and Fire Protection

20th November 2024

CUPA: CUPACLAD enhances hotel aesthetics with a creative natural slate façade

Situated at the northern edge of a newly developed retail park near Bristol, the Abbey Wood Travelodge was conceived as part of the company’s new Budget-Luxe line of hotels – it features CUPACLAD, from CUPA PIZARRAS.

Posted in Articles, Building Industry News, Building Products & Structures, Building Systems, Case Studies, Cladding, Concrete, Cement, Admixtures, Facades, Posts, Restoration & Refurbishment, Retrofit & Renovation, Walls

20th November 2024

Origin launches in-house powder coating facility

Origin’s latest investment is set to redefine industry standards as it launches its own in-house powder coating facility.

Posted in Aluminium Products, Articles, Building Industry News, Building Products & Structures, Building Systems, Doors, Glass, Glazing, Innovations & New Products, Paints, Coatings & Finishes, Restoration & Refurbishment, Retrofit & Renovation, Site Preparation, Windows

Sign up:

Sign up: