Achieving a lower carbon footprint with Axion Polymers

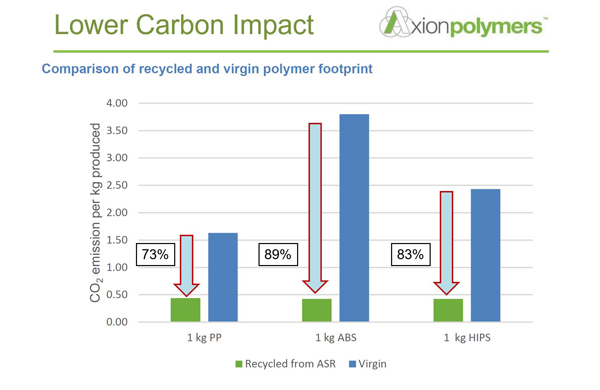

Research by Axion Polymers has revealed that recycled polymers offer a lower carbon footprint than oil-based virgin plastics.

The 2017 Axpoly Carbon Footprint Analysis reveals significant carbon savings of up to 89% for ABS, 82.5% for HIPS, and 73% for PP.

Whilst carrying out the research, the Axion team calculated that, by using one tonne of Axpoly ABS instead of virgin material to make goods, savings of approximately 3,380kgs of CO2 could be made.

Whilst carrying out the research, the Axion team calculated that, by using one tonne of Axpoly ABS instead of virgin material to make goods, savings of approximately 3,380kgs of CO2 could be made.

This is the equivalent to a 40 foot articulated lorry transporting the material 2,272 miles. On one full-load, the same lorry could be driven 45,500 miles on the equivalent CO2 savings.

Axion Polymers

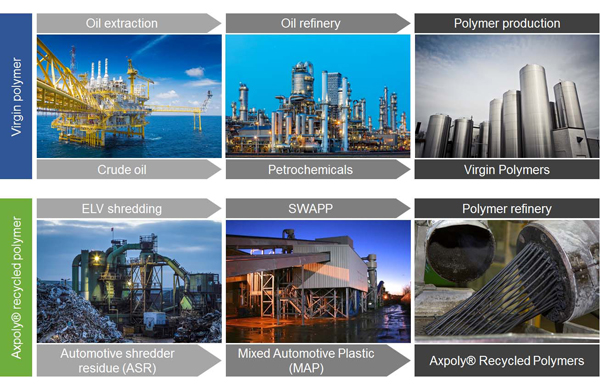

Axion Polymers produces three types of recycled polymer from its plants. Axpoly polypropylene (PP), Acrylonitrile Butadiene Styrene (ABS) and high impact polystyrene (HIPS) are re-processed from Automotive Shredder Residue (ASR), which is derived from End of Life Vehicles (ELV) and WEEE.

The Axpoly polymers can be used as a direct replacement for virgin polymers, or integrated with them to produce a high-grade polymer for demanding applications.

Axpoly Carbon Footprint Analysis

The Axpoly Carbon Footprint Analysis was motivated by a recent investment in separation processes and throughput, which has led to an increase in the yield of finished polymers.

Axion’s methodology is based on similar process stages to making oil-based polymer from crude oil, enabling a direct comparison between the process routes and resulting carbon emissions.

The results were calculated by Axion’s Head of Engineering & Research, Richard McKinlay.

‘These “new metrics” of the circular economy are the numbers that need to be considered by designers and specifiers of polymer materials when selecting plastic for use in new parts and components on all types of consumer goods and vehicles,’ he comments.

Customers can benefit from Axion’s analysis by demonstrating the carbon savings credited to their finished moulded products. The company can also provide bespoke carbon analyses on individual operations.

Axion

Tenax Road

Trafford Park

Manchester

M17 1JT

Visit Supplier's page

Latest news

17th April 2025

Nuaire shares expertise at Specifi Mechanical Services events in 2025

Indoor air quality and ventilation manufacturing specialist Nuaire is pleased to be exhibiting at the Specifi Mechanical Services events once again in 2025.

Posted in Air Conditioning, Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Exhibitions and Conferences, Facility Management & Building Services, Heating, Ventilation and Air Conditioning - HVAC, Restoration & Refurbishment, Retrofit & Renovation

15th April 2025

West Fraser: CaberDek earns top marks from Home Counties carpentry specialist

A specialist carpentry sub-contractor covering housing sites across a large swathe of the Home Counties has come to value CaberDek from the West Fraser range for a variety of reasons: not least because the high quality panel product doesn’t destroy his operatives’ electric saws!

Posted in Articles, Building Industry News, Building Products & Structures, Building Systems, Case Studies, Restoration & Refurbishment, Retrofit & Renovation, Roofs, Timber Buildings and Timber Products, Wooden products

15th April 2025

GEZE: The Role of Access Control Systems in Enhancing Building Safety

Jane Elvins, Specification and Business Development Manager at GEZE UK, delves into the role of access control systems in enhancing building safety…

Posted in Access Control & Door Entry Systems, Architectural Ironmongery, Articles, Building Industry News, Building Products & Structures, Building Services, Doors, Facility Management & Building Services, Health & Safety, Restoration & Refurbishment, Retrofit & Renovation, Security and Fire Protection

11th April 2025

Don’t Do a Dave! It’s Time to Lock FIT Show 2025 in Your Calendar!

It’s that time again – FIT Show is back! You could be forgiven for thinking there won’t be much new to see when FIT Show returns to the NEC from 29 April – 1 May. Wrong!

Posted in Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Continuing Professional Development (CPD's), Exhibitions and Conferences, Information Technology, Innovations & New Products, Restoration & Refurbishment, Retrofit & Renovation, Seminars, Training

Sign up:

Sign up: