A SWISSPACER frame in under 25 seconds speeds up production for Predari Vetri

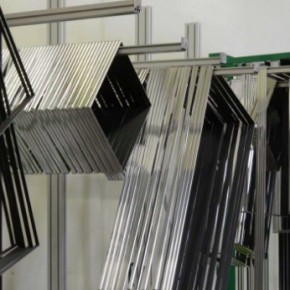

The latest ROWELDO XL frame welder from Rottler & Rüdiger now makes a perfect SWISSPACER warm edge frame in under 25 seconds, with a new robotic ‘speed-up kit’.

The ROWELDO XL is a high-performance fully-automated welding machine, ideal for large-scale sealed unit makers.

It is cutting production cycle times by one-sixth for Italian sealed unit manufacturer Predari Vetri.

The new robot welder with the ‘speed-up kit’ uses four generators – two more than previous versions – to generate more rapid energy pulses, so corners can be welded even faster than before.

The profile feed-in has been optimised and the milling length now automatically adapts to the width of the spacer bar.

This means the IGU maker achieves time savings of around 17%. The standard sized ROWELDO is still capable of creating a stable and sturdy 900 x 900mm frame in less than 30 seconds.

Andreas Geith, MD of SWISSPACER, commented: “Until now, cycle times for traditionally bent spacer bars and welded SWISSPACER spacer bars have been almost identical.

“The ‘speed up kit’ is a great advancement and makes perfect welded frames in less than 25 seconds.”

Daniele Predari, MD of Predari Vetri, explained: “As far as we can see, there are no faster options on the market. Any of our orders can include different frame sizes, spacer bar widths or colours.

“That is why the quick profile change is another advantage for us. We had reached maximum output in terms of cycle times with the bending machines.

“The increased efficiency gained from the new Roweldo XL means that two employees from frame production are now free to work on different tasks. The speed-up kit also helps us handle production peaks.

“We are one of the biggest IGU manufacturers in Italy and we always want to make the best products.”

When visiting his customers, Daniele now always brings a ready-welded SWISSPACER frame with him, something which he spoke about.

“You can see the difference and how much better it looks than a bent frame immediately,” he said.

“Our customers want straight, stable profiles and a matt surface without visible connecting points. The welded 90° corner fits perfectly. Our customers are also able to differentiate themselves on the market in this way. Some of them have already asked to be supplied exclusively with SWISSPACER.”

Andreas Geith added: “Some customers only compare the price per metre. What drives us, however, is producing an overall concept of competitive advantages for our customers – from a good price, high quality and the best physical properties to the fastest processing and excellent service.”

Existing Rottler & Rüdiger machinery, depending on the year of installation, can be retrofitted with the speed-up kit or the recently launched “Fill-it” technology.

For more info, see SWISSPACER on stand F42, Hall 11 at Germany’s glasstec, from 23-26 October or visit www.swisspacer.com

Contact:

Sonnenwiesenstrasse 15,

8280 Kreuzlingen,

Switzerland

t: 07834 162 485

e: Andrew.everett@saint-gobain.com

Visit Supplier's page

Latest news

1st April 2025

Gilberts Takes Thermal Comfort to New Heights

Gilberts Blackpool is continuing to build on its reputation as a pioneer with the unveiling of ThermaAstute™ – the most extensive range of thermally sensitive diffusers in the market.

Posted in Air Conditioning, Articles, Building Industry News, Building Products & Structures, Building Services, Facility Management & Building Services, Heating, Ventilation and Air Conditioning - HVAC, Innovations & New Products, Restoration & Refurbishment, Retrofit & Renovation, Sustainability & Energy Efficiency

1st April 2025

University of Bath Student Helps Vent-Axia Win Two Environmental Industry Awards

Leading ventilation manufacturer, Vent-Axia, is delighted that the valuable work University of Bath student Roben Els undertook during an industry placement at the company contributed to it winning two environmental industry awards.

Posted in Air Conditioning, Articles, Awards, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Heating, Ventilation and Air Conditioning - HVAC, Recruitment, Retrofit & Renovation, Sustainability & Energy Efficiency, Training

1st April 2025

Ahmarra: Fire Doors Designed for Hospitals & Healthcare Environments

Ahmarra is a leading UK specialist in fire doors for healthcare environments, having manufactured and installed thousands of bespoke doorsets for NHS hospitals across London and the South East.

Posted in Access Control & Door Entry Systems, Accessibility, Acoustics, Noise & Vibration Control, Architectural Ironmongery, Articles, Building Industry News, Building Products & Structures, Building Services, Building Systems, Doors, Facility Management & Building Services, Health & Safety, Interior Design & Construction, Interiors, Restoration & Refurbishment, Retrofit & Renovation, Security and Fire Protection, Timber Buildings and Timber Products, Wooden products

1st April 2025

Mitsubishi Electric: New intuitive, IoT-ready centralised controller offers instant access to 400 units

Mitsubishi Electric has launched a new user-friendly, touchscreen controller to offer full remote controllability, monitoring and reporting for up to 400 air conditioning units.

Posted in Air Conditioning, Articles, Building Industry News, Building Products & Structures, Building Services, Facility Management & Building Services, Heating Systems, Controls and Management, Heating, Ventilation and Air Conditioning - HVAC, Information Technology, Innovations & New Products, Pipes & Fittings, Plumbing, Posts, Research & Materials Testing, Retrofit & Renovation, Sustainability & Energy Efficiency

Sign up:

Sign up: