Aggregate Industries invests £2 million in improving its block product operations

Aggregate Industries’ Masterblock business has invested £2 million into improving its block product operations at three of its factories across the country, in response to a steady increase in demand from the housing industry.

The past couple of years has seen a surge in housing activity, with the growing need for new homes in the UK and strict targets. Therefore, there has been an increase in demand for block products, and the investment in Masterblock will enable it to increase its production capabilities of lightweight and dense concrete blocks to help meet the demand.

The £2 million improvements were made at three of its factories: Croft Block Plant in Leicestershire, and its Torr and Callow Block Plants both in Somerset.

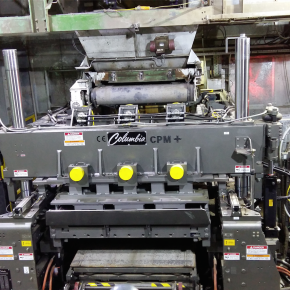

An ‘egg-laying’ operation has been added at Croft to create greater capacity to service the Midlands region. Whilst at Torr, the manufacturing area has been extended and two new machines purchased. Finally, at Callow, a state-of-the-art ‘Columbia’ static block plant has been installed.

The machine was imported from the U.S. and offers the most modern method of block making in the world and allows the team to produce high quality aggregate blocks in a variety of strengths and finishes.

Jeremy Lee, Sales Director for Building Products at Aggregate Industries, explains: “We’ve readjusted our strategy to make block products a key focus for the Building Products division and this investment into improving our current operation will help us to fulfil our orders with greater efficiency.”

Masterblock supplies aggregate concrete blocks for use in various projects, including residential developments, educational buildings, major sports stadia, office and retail developments and other commercial buildings. The range is manufactured in a wide range of sizes, strengths and finishes.

As well as supplying the product, Masterblock also offers an in-house technical team which can provide a U-value calculation service, to help take some of the time and burden away from the customer.

Visit the Aggregate Industries website

Visit Supplier's page

Latest news

28th March 2025

FLIR Si1-LD Acoustic Imaging Camera for Compressed Air Leak Detection

FLIR, a Teledyne Technologies company, introduces the Si1-LD, an industrial acoustic imaging camera that brings faster and more accurate compressed air leak detection to those operating on a modest condition monitoring budget.

Posted in Acoustics, Noise & Vibration Control, Articles, Building Industry News, Building Products & Structures, Building Services, Facility Management & Building Services, Information Technology, Innovations & New Products, Retrofit & Renovation, Sustainability & Energy Efficiency, Thermal Imaging and Monitors

28th March 2025

LIFTEX 2025 Seminar programme announced

Registration has opened for LIFTEX 2025. Now in its 37th year, LIFTEX 2025 is the UK’s only dedicated exhibition for the lift, escalator and access industry and takes place only once every three years.

Posted in Access Control & Door Entry Systems, Accessibility, Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Regulations & Accreditations, Building Services, Exhibitions and Conferences, Facility Management & Building Services, Health & Safety, Retrofit & Renovation, Security and Fire Protection, Seminars

28th March 2025

MCRMA welcomes ArcelorMittal UK to membership

A UK division of the global steelmaking business ArcelorMittal has become the latest new member of the MCRMA, the industry association representing the metal building envelope sector.

Posted in Articles, Building Associations & Institutes, Building Industry News, Building Products & Structures, Building Systems, Cladding, Facades, Posts, Restoration & Refurbishment, Retrofit & Renovation, Roofs, Steel and Structural Frames, Walls

28th March 2025

Abloy: Managing access and security in Telecoms infrastructure

Telecommunications infrastructure underpins much of the world’s economy and critical services, but the industry is vulnerable to physical threats, from sabotage to theft and accidental damage, as Abloy UK explains here…

Posted in Access Control & Door Entry Systems, Architectural Ironmongery, Articles, Building Industry News, Building Products & Structures, Building Regulations & Accreditations, Building Services, Doors, Facility Management & Building Services, Information Technology, Innovations & New Products, Posts, Publications, Research & Materials Testing, Retrofit & Renovation, Security and Fire Protection

Sign up:

Sign up: