Air Compressors: How Do They Work?

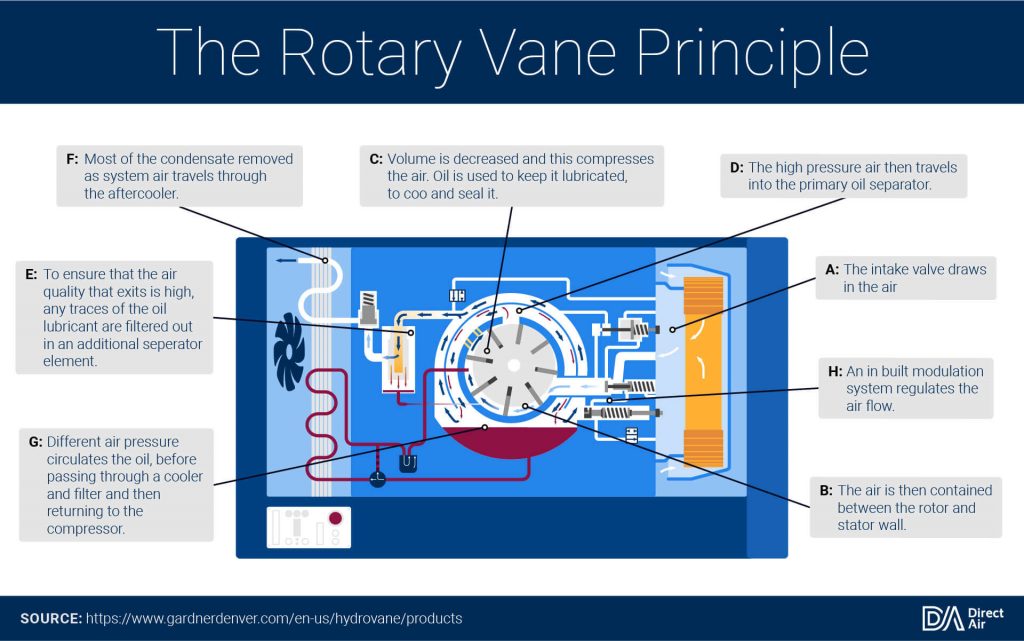

An incredibly valuable tool, air compressors are essential to many industries and tasks. With a number of uses from pneumatic tools to air conditioners, Direct Air has created a graphic to give a true understanding of how they work.

There are many varieties of these machines, below is a brief overview to help you choose the right air compressor for the job at hand.

Single and Dual Phase

These models follow a similar method to each other, dual compressors simply have one extra step in their process. Air is drawn into a cylinder and compressed with a single piston movement.

Dual phase follows this but will send the air into a second cylinder to be compressed again. Both then send the air to a storage tank until required.

Dual phase compressors are typically suited to an industrial environment while single phase are more commonly used within DIY.

Oil-Free and Oil-based

All air compressors must be lubricated in order to draw air in efficiently and safely.

Oil-free have a non-stick coating, such as Teflon within the cylinder and oil-based require oil to be applied to the piston area.

Oil-free are typically cheaper to purchase and maintain but will often have a shorter lifespan as this coating will eventually wear down.

Oil-based are more costly to purchase and require more maintenance and regular oil checks. They also have more elements to the machine so are heavier.

However, they are more robust and suited to heavy-duty tasks, on average will last longer than their counterparts.

Fixed and Variable

A fixed speed air compressor will send a continuous and consistent power stream to the motor. This in turn gives reliable frequency. They are cheaper to buy and maintain.

A variable speed compressor automatically adjusts the speed of the motor in accordance with the demand for air. This means they are far more energy efficient than a fixed speed and therefore more affordable to run.

Scroll Compressors

The most common form of air compressor, a piston travels downwards to decrease pressure and forces the cylinder open. Air is drawn in and then forced out at a higher pressure point when the piston travels up again.

Scroll compressors are more energy efficient and can cool down quickly, they are however harden to maintain.

Rotary Screw Compressors

Instead of pistons, these compressors use rollers. These are positioned in the middle of the shaft with the side of the roller always in contact with the wall. These then rotate at an extreme speed, mimicking that of a piston.

Rotary screw compressors have a great power capacity and are easy to maintain. They do require regular maintenance checks and have limited cooling abilities.

Low Noise Air Compressors

A typical complaint of air compressors is the loud noise levels. Low noise air compressors are available. These work by having an acoustic chamber built in that contains the noise and reduces the decibel level to around 40dB.

Latest news

2nd April 2025

FIT Show 2025 Launches Innovative Marketplace Feature to Enhancing Value for Installers

FIT Show, the UK’s leading event for the window, door, flat glass, hardware, and roofing industries, is excited to announce the launch of a brand new Marketplace feature at its upcoming 2025 event (Birmingham NEC, 29 April – 1 May).

Posted in Architectural Ironmongery, Articles, Building Industry Events, Building Industry News, Building Products & Structures, Doors, Exhibitions and Conferences, Glass, Glazing, Hand Tools, Innovations & New Products, Plant, Equipment and Hire, Power Tools, Restoration & Refurbishment, Retrofit & Renovation, Roofs, Seminars, Training, Windows

2nd April 2025

Hi-spec deployment of EJOT Colorfast at new Birmingham logistics park

EJOT Colorfast fasteners have been used extensively in the construction of eight new high-specification warehousing and logistics buildings at the Urban 8 Logistics Park in King’s Norton, Birmingham.

Posted in Articles, Building Industry News, Building Products & Structures, Building Systems, Case Studies, Facades, Restoration & Refurbishment, Retrofit & Renovation, Roofs, Walls

2nd April 2025

SWA member delivers ‘fresh Hope’ for university’s Sustainable Building department

A detailed contract to restore an iconic Art Deco building in the heart of Birmingham’s Jewellery Quarter was carried out by Steel Window Association member, The Window Repair Company (Northwest) Limited.

Posted in Articles, Building Associations & Institutes, Building Industry News, Building Products & Structures, Building Systems, Case Studies, Glass, Glazing, Restoration & Refurbishment, Retrofit & Renovation, Steel and Structural Frames, Sustainability & Energy Efficiency, Windows

1st April 2025

Gilberts Takes Thermal Comfort to New Heights

Gilberts Blackpool is continuing to build on its reputation as a pioneer with the unveiling of ThermaAstute™ – the most extensive range of thermally sensitive diffusers in the market.

Posted in Air Conditioning, Articles, Building Industry News, Building Products & Structures, Building Services, Facility Management & Building Services, Heating, Ventilation and Air Conditioning - HVAC, Innovations & New Products, Restoration & Refurbishment, Retrofit & Renovation, Sustainability & Energy Efficiency

Sign up:

Sign up: