Impact of ErP directive on plumbers and installers

GUEST BLOG: Andrew Clarke – Category Manager, Heating from Graham Plumbers’ Merchant

With the ErP directive now firmly in place – having come into effect on 26th September – it’s important to make sure that installers are aware of what the new legislation means for them. Here, Andrew Clarke – Category Manager, Heating from Graham Plumbers’ Merchant looks at what the ErP directive is and what plumbers and installers must do to ensure they are compliant.

The ErP directive has been created to help improve product efficiency, covering all heating and hot water products, up to 400kW, having been designed to help the EU achieve its target to reduce energy use by 20% and increase the share of renewable energies by 20% by 2020.

The ErP directive has been created to help improve product efficiency, covering all heating and hot water products, up to 400kW, having been designed to help the EU achieve its target to reduce energy use by 20% and increase the share of renewable energies by 20% by 2020.

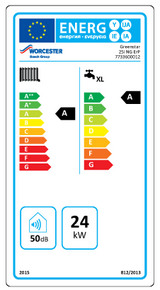

Of course, now the new regulations are in place, there are different responsibilities required from manufacturers, merchants and importantly, installers. For example, under the new Energy Labelling rules, manufacturers will be responsible for providing new energy labelling for all of their products, while installers will be responsible for providing an energy label for any system they install.

This means installers will need to learn how to calculate a system’s efficiency figure, based on its different components. This system efficiency figure must then be added to a ‘package’ label to complete the installation.

Since the ErP is already in place, it is important for the installer to familiarise themselves with the overall process. Energy Labelling is the white label, seen on most washing machines and televisions for example, that outlines, by ‘band’, how efficient a product

Where just one product is installed, the installer’s obligation is to pass on the manufacturer’s Energy Label. However, when installing a complete system, it is the installer’s responsibility to provide a package label.

The process requires the production of a package document, known as a package fiche, and a package label that provides the combined system energy efficiency rating rather than the individual component ratings.

The installer’s responsibility is to provide a completed package label with every quotation to enable the consumer to make an informed choice of package. The ErP directive also covers the impact of controls on the package. These are defined using ‘classes’ – these run from Class I (an on/off room stat) right through to a Class VIII (multi sensor room control for use with modulating heating appliances). Each of these control ‘classes’ equates to a certain percentage of uplift in a system’s efficiency – for example, a Class VI weather compensating control and room thermostat can add up to 4% efficiency to the heating system.

In order to comply with the ErP directive, installers do not need to complete any additional training, but it is strongly recommended that they familiarise themselves with the changes as soon as possible – under the guidance of their local merchant if necessary – so they can be confident of the entire procedure required.

The manufacture and associated installation of heating systems that are not compliant could mean legal action is taken or even criminal prosecution for the offending manufacturer or installer, with the National Measurement Office responsible for enforcing the ErP directive itself.

Where ErP compliance is concerned, there is one area in which some leniency is allowed – if as an installer, a boiler has been purchased prior to 26th September and therefore does not contain the new ErP labelling documents in the box, it can still be sold to the customer and an energy label will not be required, since it was on the market before the date that the new ErP regulations took effect.

It is understandable that there will however be questions from installers regarding ErP regulations – in that sense, manufacturers and merchants do have a level of responsibility to uphold when it comes to providing advice and guidance. Bearing that in mind, installers are strongly urged to speak to their merchant when purchasing goods to ensure they are up to speed with exactly what’s required from them now that the ErP has been rolled out.

Latest news

13th March 2025

Vent-Axia Publishes Free eBook to Help Social Housing Landlords Navigate Awaab’s Law

Leading British ventilation manufacturer Vent-Axia has published a free eBook, ‘Ensuring Safe Housing Conditions: Focusing on Mould and Damp Conditions’.

Posted in Air Conditioning, Articles, Building Industry News, Building Products & Structures, Building Regulations & Accreditations, Building Services, Damp & Waterproofing, Facility Management & Building Services, Health & Safety, Heating, Ventilation and Air Conditioning - HVAC, Innovations & New Products, Publications, Research & Materials Testing, Retrofit & Renovation

13th March 2025

First Processing Industries apprenticeship completed within West Fraser

West Fraser is pleased to announce that the company’s continued investment in apprenticeships, as well as wider staff development training, has seen one recruit successfully complete his modern apprenticeship.

Posted in Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Regulations & Accreditations, Building Systems, Recruitment, Restoration & Refurbishment, Retrofit & Renovation, Timber Buildings and Timber Products, Training, Walls, Wooden products

11th March 2025

ADSA’s 40 Years of Innovation

The Automatic Door Suppliers Association (ADSA) is kicking off its 40th anniversary with the launch of an animated timeline that showcases its incredible journey and industry-defining achievements.

Posted in Access Control & Door Entry Systems, Architectural Ironmongery, Articles, Building Associations & Institutes, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Doors, Facility Management & Building Services, Health & Safety, Innovations & New Products, Recruitment, Retrofit & Renovation, Security and Fire Protection, Training, Videos

11th March 2025

Senior answers the call at Merseyside’s new state-of-the-art fire station

Safe, secure, and sustainable aluminium fenestration solutions from Senior Architectural Systems have been installed at Merseyside Fire & Rescue Service’s brand-new fire station in Aintree.

Posted in Aluminium Products, Articles, Building Industry News, Building Products & Structures, Building Systems, Case Studies, Curtain Walling, Doors, Facades, Glass, Glazing, Restoration & Refurbishment, Retrofit & Renovation, Sustainability & Energy Efficiency, Walls, Windows

Sign up:

Sign up: