Why Should You Use 3D Printing and CNC Machining Solutions When Building Your Home?

The construction industry is constantly evolving, changing the way that different companies work. These days, it’s essential for them to remain up-to-date with all the latest trends and developments in the technology utilised by the construction industry. This allows the contractors to stay prepared for the future and do a better job.

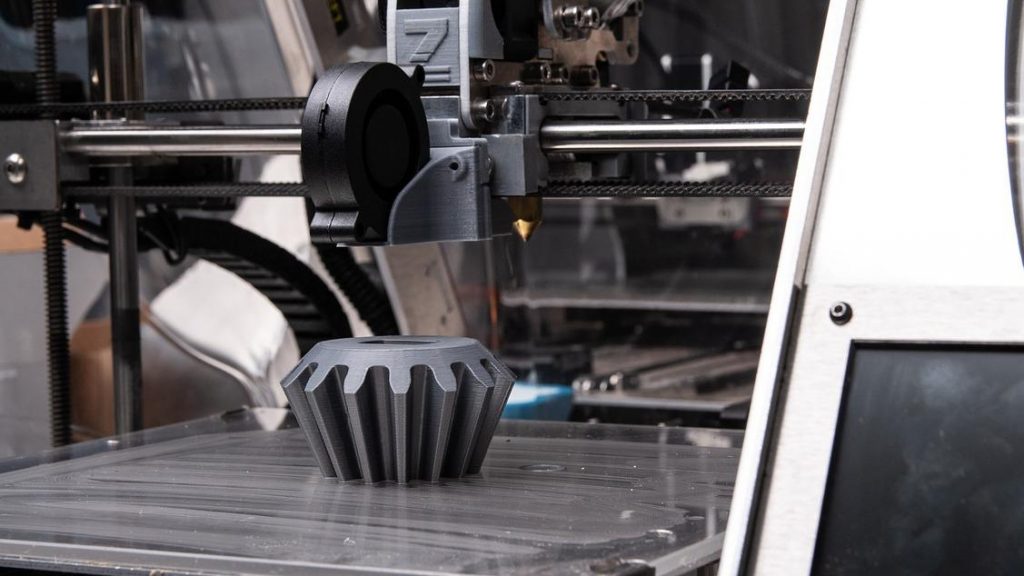

Advancements are driving the industry forward, and today, people who decide to build a home in The San Fernando Valley, Sommerville Park, or any other mesmerising place can take advantage of solutions such as 3D printing and CNC machining. Shortly put, the former is a fast-growing and incredibly cost-effective technology that allows to create different products by adding layers, while the latter provides greater accuracy and creates parts by subtracting unnecessary material.

Each of these technologies can be used in construction and provide innovative methods to handle common problems as well as comprehensive manufacturing solutions.

That being said, read the article below if you’re planning to build your own home and want to learn more about how you could use 3D printing and CNC machining in the process…

Better Structural Integrity

CNC machines are often praised for their high accuracy and ability to create parts with virtually zero defects. Because many precision turning machines operate autonomously and without the need for manual intervention, they eliminate the possibility of human errors seeping into the manufacturing process. Codes and software programs take care of most of the process, meaning that CNC machines can deliver accuracy without any flaws.

You can use parts and tools produced with CNC machines when building your house. The products they make are exact in every measure, which allows tight, square, true fits that then ensure the structural integrity of the whole build.

Furthermore, using parts produced by CNC machines reduces the need for highly skilled labour in the construction workflow. The machines can make their cuts and produce parts such as CNC turning parts at greater volume than a human crew and with incredible precision.

Additionally, more accurate three-dimensional cuts produced by CNC machines result in stronger, higher-performing, tighter structural parts of a home. This provides both the homeowners and the construction companies with more durable and reliable materials, which help ensure that your home will be a structurally sound build.

Innovate Designs

Using 3D printing in the construction industry brings many innovative solutions. This technology can significantly improve your project planning because it can be easily used at every design stage, depending on your needs.

For instance, you can take the computer-aided design (CAD) of the building, which is a technical drawing that includes all the essential parameters, and use a 3D printer to print a model of the construction. This way, it’s much easier to visualise how the drawing will look when the project is ready. It can also be used to see if any changes might be needed and help find better design solutions.

If you happen to have any questions or concerns regarding the project of your home, seeing it printed in 3D will help you understand all the nuances and work with your architect and contractor toward the best solutions possible. Also, the earlier you address any issues you might have with the project, the better, as changes at the design stage will cost much less than if you wanted to change something in the middle of the construction process.

Fast Production

Using 3D printing and CNC machining in the construction industry equals a reduction in the production time. Depending on the part you need, it might even be ready in a matter of hours or days. Of course, complex parts will almost certainly take longer to produce, but the benefits are still there, as your patience will be rewarded with high-quality, strong, and accurate parts.

3D printers and CNC machines are highly automated, meaning that the possibility of human error is reduced to nearly zero. Both machines need to be monitored by people but can perfectly manage to produce the necessary parts without human intervention. In general, there is no need for different materials, additional support, or other aspects that traditional methods might require.

Less Material Waste

Using 3D printing and CNC machining in the construction industry saves a lot of production costs on material waste which might simultaneously lower the price you’ll need to pay for certain products and parts. While 3D printers use the exact amount of products they need, CNC machines run on software programs that develop the best way to produce a component without waste.

3D printers work layer by layer, and the lattice structures inside the printed-out parts allow for a huge cost reduction. Additionally, they can use recycled materials, which benefits the environment. Some printers use recycled plastic bottles, while others are even designed to print recycled plastics, rubber, and composite materials containing wood, hemp, flax, and other biomaterials. These innovations are still relatively new, but progress is being made constantly.

Similarly, CNC machines often operate on repeatable software programs that help make smart use of the raw material available. As a result, most highly advanced CNC machines can help manufacturers cut down waste significantly. Moreover, CNC machine shavings (depending on what was being milled) can go into metal-oriented scrap bins to be returned to the manufacturer of the material, re-melted, and then reused in other projects.

In Conclusion

As you can see, both 3D printing and CNC machining solutions can prove to be incredibly useful in the process of building your own home. 3D printing allows you to create prototypes for your home, which means that you can tweak the design and make adjustments before you start building the final model, while CNC machining ensures better structural integrity of your build. Both technologies allow for faster production of different parts and can significantly cut down material waste.

3D printing and CNC machining helps to manage the whole production process, from the early stages to the final product. Based on this information, you will be able to make a more informed decision regarding the solutions you want to utilise when building your home.

Latest news

30th April 2025

Digital Construction Week announces seminar programme for its landmark 10th edition

Digital Construction Week (DCW) returns to ExCeL London on 4 – 5 June 2025 with its most impactful programme yet. It brings together the best and brightest from across AECO, for two days of practical learning and idea sharing.

Posted in Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Building Systems, Exhibitions and Conferences, Information Technology, news, Restoration & Refurbishment, Retrofit & Renovation, Seminars

29th April 2025

Senior pledges to ‘bee’ part of the solution with new biodiversity initiative

Senior Architectural Systems has installed its first on-site beehive, marking another step forward in its commitment to sustainability and biodiversity.

Posted in Articles, Building Industry News, Building Products & Structures, Building Services, Curtain Walling, Doors, Glass, Glazing, Innovations & New Products, news, Restoration & Refurbishment, Retrofit & Renovation, Sustainability & Energy Efficiency, Walls, Windows

29th April 2025

West Fraser range delivering key benefits for South-East carpentry company

An experienced carpenter and building site manager who has recently set up his own company is using high performance panel products from the West Fraser range.

Posted in Articles, Building Industry News, Building Products & Structures, Building Systems, Case Studies, Garden, Restoration & Refurbishment, Retrofit & Renovation, Sustainability & Energy Efficiency, Timber Buildings and Timber Products

29th April 2025

CPD Courses Available Online From Ecological Building Systems

Ecological Building Systems, a leading supplier of natural building products for sustainable construction, has revealed its comprehensive CPD programme for the year ahead.

Posted in Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Continuing Professional Development (CPD's), Information Technology, Innovations & New Products, Insulation, Restoration & Refurbishment, Retrofit & Renovation, Seminars, Sustainability & Energy Efficiency, Training, Walls, Waste Management & Recycling

Sign up:

Sign up: