Catenary curves in Canada

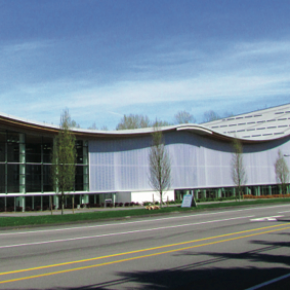

Both a destination training facility and a key venue for regional, national and international competitions, the Grandview Heights Aquatic Centre is an anchor for the developing community in Surrey, Canada. Find out more in the latest issue of ABC+D magazine.

Constructed to meet the needs of a diverse population in one of Canada’s fastest growing cities, the Grandview Heights Aquatic Centre features an undulating roof structure with hanging timber cables, suspended between large concrete buttresses.

While most catenary systems have historically used steel cables, Fast + Epp took a novel approach, pioneering one of its most ambitious designs in the Vancouver firm’s 30-year history.

The engineers chose wood as a cost-effective, structurally- efficient and aesthetically-pleasing alternative, cleverly balancing form and function. The resulting structure fulfills the client’s desire for an iconic building that will be a catalyst for civic growth and is believed to be the world’s most slender long span timber catenary roof.

Creativity and innovation

For an aquatic centre of such size, the design team recognized the roof structure as a crucial point of visual interest.

The architect challenged the team to think outside the box and explore spanning the primary structure across the 55m longer span rather than the short span – despite knowing this break with convention had the potential to substantially increase costs.

Shying away from typical ribbed ceilings of steel that would eventually corrode from the chemicals and harsh humidity

of an aquatic environment, Fast + Epp chose to use wood for its hanging suspension roof.

The architect (at first somewhat surprised by the audacity of a timber catenary roof ) jumped on board with the unconventional approach, working hard with the entire team to overcome obstacles.

The almost-exclusively wood solution made use of small

5 x 10” long span glue-laminated wood beams, acting as cables under a double layer of plywood sheets as the main structural system. They hang between narrow, thin concrete slabs that transfer tension loads to post-tensioned concrete butresses.

The roof not only achieves the significant clear spans required for the pools, but uses only a 300mm deep structure (compared with a typical 3,000mm steel truss structure), thereby minimizing the building volume and ensuring long- term operational cost savings. The deep pool excavations were efficiently utilized to bury concrete foundations deep underground and resist the overturning forces.

A key to the success of the structural concept was the refinement of the roof geometry. The clear height requirements varied drastically from extremely high at dive towers and the water slide to low over swim areas. Thus the roof shape was warped in order to minimize building volume and create a slope for rainwater management.

Initially, this resulted in no less than 14 radii of glulam cable curvatures and prohibitive costs for each custom glulam jig manufacture – enough to sink the structural concept.

The geometry was then refined so that only one radius of curvature and jig was used for every glulam cable.

By simply lengthening and raising the ends of each adjacent glulam slightly, the warped roof geometry was achieved by much more economical means. The spaghetti-like glulams were erected on site in just 12 days.

Shying away from typical ribbed ceilings of steel… Fast + Epp chose to use wood for its hanging suspension roof..

Sustainability and value

Compared to a more typical box with a flat roof to accommodate tall diving towers, GHAC’s roof shape saves money in the long-run, by reducing the cubic volume of air to be heated and de-humidified and decreasing operational costs for the client. The design represents outstanding value for money and met the city’s budgetary expectations.

The facility is seeking LEED-certification and meets stringent FINA standards to host regional, provincial, national and international sporting events in its ten-lane, 50m Olympic- size competition pool and dive platform.

However, the best contribution a structural engineer can make to sustainability is to design efficient structures with minimal material – Fast + Epp’s roof structure delivers on this. By reducing the effective roof structure depth from 3,000 to 300mm, the building volume was drastically reduced and significant life- cycle energy cost savings were achieved.

Moreover, the best scientific research tells us that wood is a much more sustainable material versus concrete and steel; it is a rapidly renewable resource with low-embodied energy and carbon-sequestering capabilities.

The façade structure (up to 20m high) was constructed with steel tube columns, which serve a double function – they not only resist wind loads but are perforated and connect to the basement air supply ducts, acting as ventilator ducts to prevent condensation at exterior glazing. This eliminated costly and unsightly mechanical ducting.

The design maximizes security and accessibility, with clear views from the central lobby into the natatorium. The linear orientation of the roof, parallel to the pool lanes is a benefit to competitive swimmers for orientation in the water.

Initial reaction to the superstructure design of the building suggests that its striking aesthetic expression and ambiance will make it a favourite for years to come – and a pivotal first piece in a larger recreational master- plan to be built over the next decade.

Latest news

8th April 2025

First look at industry speakers for GEO Business 2025

GEO Business, the UK’s premier geospatial event, is set to return to ExCeL London on 4 – 5 June 2025, bringing together the brightest minds in the industry.

Posted in Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Exhibitions and Conferences, Information Technology, Innovations & New Products, Restoration & Refurbishment, Retrofit & Renovation, Seminars

8th April 2025

Digital Construction Week 2025 announces first wave of industry-leading speakers

Digital Construction Week (DCW), the UK’s premier event for digital innovation in the built environment, is set to return to ExCeL London on 4 – 5 June 2025.

Posted in Articles, BIM, Infrastructure & CAD Software, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Building Systems, Civil Engineering, Exhibitions and Conferences, Hard Landscaping & Walkways, Health & Safety, Information Technology, Innovations & New Products, Landscaping, Retrofit & Renovation, Seminars

7th April 2025

Abloy UK provides bespoke access control solution for CPA Group’s Lanarkshire HQ

Abloy UK has supplied CPA Group with its PROTEC2 CLIQ solution to streamline access control and protect assets at its headquarters in Shotts, Lanarkshire.

Posted in Access Control & Door Entry Systems, Architectural Ironmongery, Articles, Building Industry News, Building Products & Structures, Building Services, Case Studies, Doors, Facility Management & Building Services, Health & Safety, Restoration & Refurbishment, Retrofit & Renovation, Security and Fire Protection

7th April 2025

ASSA ABLOY EMEIA: A new generation of reader is added to the Aperio digital access family

There is now a way to control access digitally, effectively and wire-free, thanks to ASSA ABLOY EMEIA…

Posted in Access Control & Door Entry Systems, Architectural Ironmongery, Articles, Building Industry News, Building Products & Structures, Building Services, Doors, Facility Management & Building Services, Health & Safety, Information Technology, Innovations & New Products, Posts, Retrofit & Renovation, Security and Fire Protection

Sign up:

Sign up: