Delta Membranes launches new 895 Foul Sump Pump Chamber

Delta Membrane Systems Limited is launching the new 895 Foul Sump Pump Chambers, pushing the boundaries of what is possible in sump pump applications.

The Delta 895 chambers are designed for foul and grey water collection. The Delta V3 Foul Packaged Pump Stations are suitable for collecting wastewater from the kitchens, bathrooms and/or utility rooms and discharging this into the mains drainage system.

V3 Foul is an effective way of moving foul/grey water to where it needs to be.

Advantages of the 895 Sump Pump Chambers

– New unique design

– Finite Element Analysis (FEA)

– Preformed Base Plate for pump location and install stability

– Preformed float backet for Delta HLA

– Sealing lip

– Compatible with the Delta V3 Foul sump pumps

– New slim lid able to withstand pedestrian traffic

– Increased storage capacity

New unique design

The Delta 895 chamber offers the next level in foul water collection chambers. Its compact new size doesn’t compromise in capacity or durability. This specially designed chamber offers a large storage dimension (not forgetting the all-important cost savings), plus less excavation costs, less labour costs and less requirement for concrete/steel (when housed).

Finite Element Analysis (FEA)

Finite element analysis is the process of replicating the behaviour of a part or assembly (in this case the Delta 895 chamber) under given conditions so that it can be assessed using the finite element method (FEM).

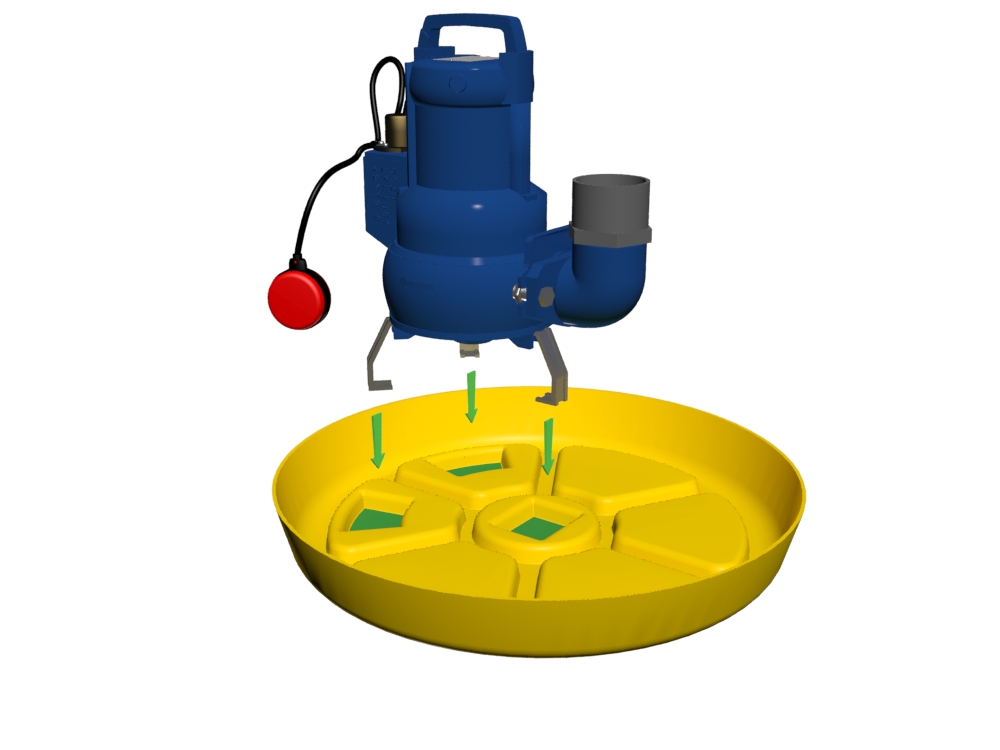

Preformed Base Plate for pump location and install stability

The uniquely designed preformed base plate, helps installers locate within the 895 chamber the correct location for the Delta V3 Foul pump to sit, negating incorrect installation.

External Sealing lip

To reduce risk, Delta adds an external sealing lip to the 895 chambers. This sealing lip will allow installers to apply Delta AKTI-VO 201 (swellable mastic) to the entire external lip locator of chamber. Once the sump chamber is backfilled, this seal will offer a continuous waterproofing approach.

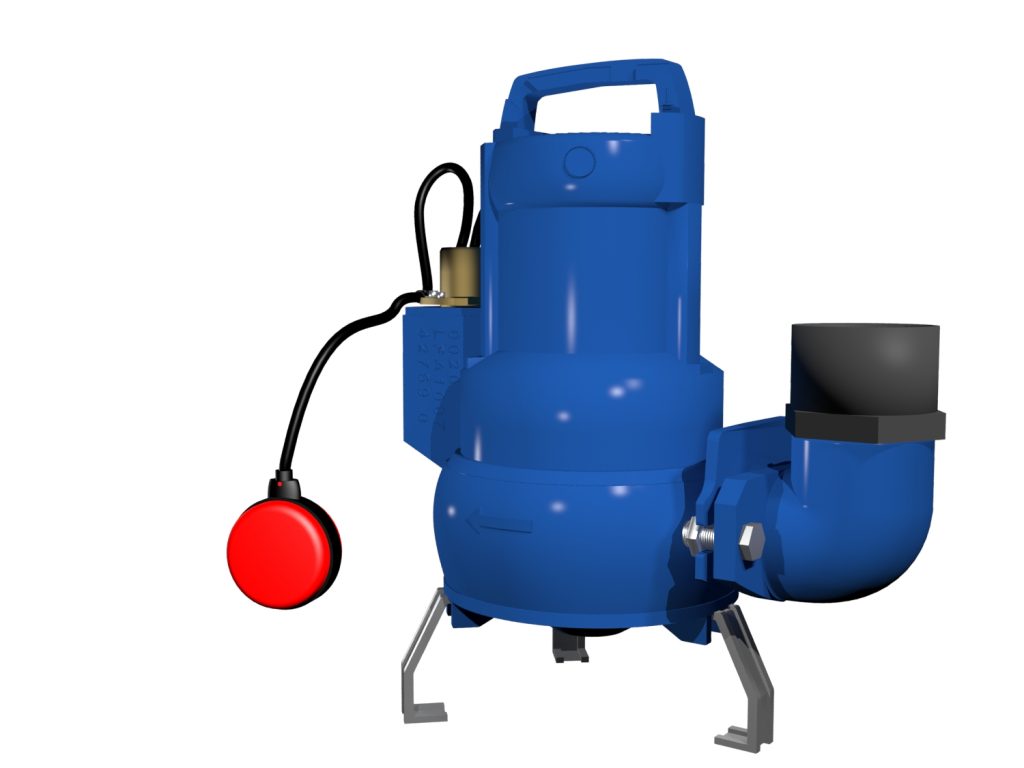

Compatible with the Delta V3 Foul Sump Pump

The Delta 895 chamber is fully compatible with the Delta V3 Foul submersible pump. Superior design, precision manufacturing and high-quality assurance has made Delta a trusted name for package pump stations.

The robust and reliable Delta Foul V3 is an exceptionally popular choice with waterproofing professionals due to its generous sized motor, thermal overload protection and ease of installation.

The powerful Vortex pump offers innovative design and advanced technology making it extremely dependable even when subjected to continuous use (subject to correct installation).

New slim lid able to withstand pedestrian traffic

Follow-on construction trades, on occasion, can be hazardous to basement drainage systems, and it should be accepted a certain amount of risk to the pump stations may be encountered. A damaged chamber lid can lead to debris and other construction waste entering the pump system.

An inoperable chamber lid can make it impossible to inspect, service or commission the sump pump system. The Delta 895 chamber not only has a slimmer lid to previous models, but it is also able to withstand pedestrian traffic, mitigating any follow-on trade accidents.

Delta Pumps are proud to be manufacturing and fabricating all its sump pump chambers from its new warehouse facilities in a new dedicated Pump Distribution Hub close to its Epping Headquarters. This will enhance the company’s ability to serve its nationwide customer base.

To explore the new range of Delta Pumps, visit Package Pumps and Basement Drainage Systems – Delta Membranes.

Whatever the needs of your project, you can rely on Delta’s Technical Team to ensure you get the right advice, support, and practical help at exactly the right time its required. Call 01992 523 523 or email info@deltamembranes.com.

Delta Membrane Systems,

Delta House,

Merlin Way,

North Weald,

Epping,

Essex,

CM16 6HR

United Kingdom

Visit Delta Membrane Systems' website

Visit Supplier's page

Latest news

17th April 2025

Nuaire shares expertise at Specifi Mechanical Services events in 2025

Indoor air quality and ventilation manufacturing specialist Nuaire is pleased to be exhibiting at the Specifi Mechanical Services events once again in 2025.

Posted in Air Conditioning, Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Exhibitions and Conferences, Facility Management & Building Services, Heating, Ventilation and Air Conditioning - HVAC, Restoration & Refurbishment, Retrofit & Renovation

15th April 2025

West Fraser: CaberDek earns top marks from Home Counties carpentry specialist

A specialist carpentry sub-contractor covering housing sites across a large swathe of the Home Counties has come to value CaberDek from the West Fraser range for a variety of reasons: not least because the high quality panel product doesn’t destroy his operatives’ electric saws!

Posted in Articles, Building Industry News, Building Products & Structures, Building Systems, Case Studies, Restoration & Refurbishment, Retrofit & Renovation, Roofs, Timber Buildings and Timber Products, Wooden products

15th April 2025

GEZE: The Role of Access Control Systems in Enhancing Building Safety

Jane Elvins, Specification and Business Development Manager at GEZE UK, delves into the role of access control systems in enhancing building safety…

Posted in Access Control & Door Entry Systems, Architectural Ironmongery, Articles, Building Industry News, Building Products & Structures, Building Services, Doors, Facility Management & Building Services, Health & Safety, Restoration & Refurbishment, Retrofit & Renovation, Security and Fire Protection

11th April 2025

Don’t Do a Dave! It’s Time to Lock FIT Show 2025 in Your Calendar!

It’s that time again – FIT Show is back! You could be forgiven for thinking there won’t be much new to see when FIT Show returns to the NEC from 29 April – 1 May. Wrong!

Posted in Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Continuing Professional Development (CPD's), Exhibitions and Conferences, Information Technology, Innovations & New Products, Restoration & Refurbishment, Retrofit & Renovation, Seminars, Training

Sign up:

Sign up: