Delta: What is positive side/negative side Waterproofing?

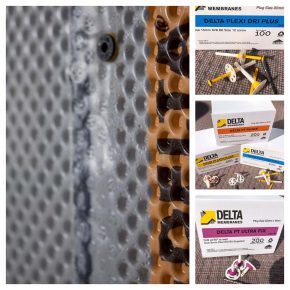

One of the most interesting questions in the waterproofing sector is what exactly is positive side and negative side waterproofing? It is a great question, say Delta Membranes, and one that the company have explored in this piece.

Delta explains that there are many different approaches to structural waterproofing. The construction methods will in part contribute to the specification of types of waterproofing systems (positive or negative side) and may also determine the overall structural waterproofing strategy.

Structural waterproofing falls into three categories

Type A: Barrier Protection

Type B: Structurally Integral Protection

Type C: Drained Protection

With three grades

Grade 1: Some water seepage and damp are tolerable depending on the intended use

Grade 2: No water penetration is acceptable

Grade 3: No dampness or water penetration is acceptable

From these categories, Delta offer designs based on

– Positive side waterproofing

– Negative side waterproofing

– Integral waterproofing

Integral waterproofing (Type B Structurally Integral Protection) is comprised of admixtures that are incorporated into the concrete mixture during the initial pour and are not usually seen as a ‘positive’ or ‘negative’ side waterproofing solution.

On some occasions, warranty providers may ask for two forms of waterproofing, meaning both the positive and negative sides are offered protection.

What is positive side waterproofing

Positive side applied waterproofing is an external waterproofing system. A waterproofing system installed to the exterior face of the below ground structure.

A suitably designed positive system can protect the structure and the interior against the effects of moisture and pressurised water.

A positive side applied system takes the water pressure in conjunction with the structure to which it is applied to effectively create a permanent consistent barrier.

What is negative side waterproofing

Negative side applied waterproofing is applied to the internal surfaces of the structure, usually when there is no access or ability to either get access to the access to the external surfaces or where continuity is not possible.

An internal negative side system is often reliant on the ability of those surfaces in accept the waterproofing treatment. A general rule of thumb is that an internally applied system is as good as the sum of the integrity of the structure and the preparation undertaken.

Negative side waterproofing, in some instances, has the capability of dealing with an incredible 13 bar pressure (this equates to just over 130m head of water!).

Both positive and negative waterproofing systems have pros and cons; for example, a piled structure cannot be waterproofed on the positive side and it is also difficult to waterproof structures where access is limited.

Internal waterproofing for example, can be applied to piled structures because access is not a problem and continuity is not a problem.

Full site investigations are important when mitigating and reducing risk in waterproofing design. The results will have a bearing not only on the design but on the waterproofing system itself – positive (external)/negative (internal).

Whilst findings of a site investigation are often seen as conclusive, it needs to be remembered that this is just a ‘snapshot in time’.

It should be assumed that water will come to bear against the full height of the below ground structure at some time in its life.

The system designed may be acceptable at the time of construction meeting the ‘snapshot in time’ investigations, however this system may not be adequate for environmental changes of the future.

The decision to use positive side or negative side waterproofing can be made after exploring

– Changes in water tables

– Changes in hydrostatic pressure

– Thermal changes

– Dynamic Movement

– Heave

– Subsidence

– Clay soils

– Changes in environment

– Stress

– Changes in ground drainage

– Structural stability

Delta Membrane Systems,

Delta House,

Merlin Way,

North Weald,

Epping,

Essex,

CM16 6HR

United Kingdom

Visit Delta Membrane Systems' website

Visit Supplier's page

Latest news

17th April 2025

Nuaire shares expertise at Specifi Mechanical Services events in 2025

Indoor air quality and ventilation manufacturing specialist Nuaire is pleased to be exhibiting at the Specifi Mechanical Services events once again in 2025.

Posted in Air Conditioning, Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Exhibitions and Conferences, Facility Management & Building Services, Heating, Ventilation and Air Conditioning - HVAC, Restoration & Refurbishment, Retrofit & Renovation

15th April 2025

West Fraser: CaberDek earns top marks from Home Counties carpentry specialist

A specialist carpentry sub-contractor covering housing sites across a large swathe of the Home Counties has come to value CaberDek from the West Fraser range for a variety of reasons: not least because the high quality panel product doesn’t destroy his operatives’ electric saws!

Posted in Articles, Building Industry News, Building Products & Structures, Building Systems, Case Studies, Restoration & Refurbishment, Retrofit & Renovation, Roofs, Timber Buildings and Timber Products, Wooden products

15th April 2025

GEZE: The Role of Access Control Systems in Enhancing Building Safety

Jane Elvins, Specification and Business Development Manager at GEZE UK, delves into the role of access control systems in enhancing building safety…

Posted in Access Control & Door Entry Systems, Architectural Ironmongery, Articles, Building Industry News, Building Products & Structures, Building Services, Doors, Facility Management & Building Services, Health & Safety, Restoration & Refurbishment, Retrofit & Renovation, Security and Fire Protection

11th April 2025

Don’t Do a Dave! It’s Time to Lock FIT Show 2025 in Your Calendar!

It’s that time again – FIT Show is back! You could be forgiven for thinking there won’t be much new to see when FIT Show returns to the NEC from 29 April – 1 May. Wrong!

Posted in Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Continuing Professional Development (CPD's), Exhibitions and Conferences, Information Technology, Innovations & New Products, Restoration & Refurbishment, Retrofit & Renovation, Seminars, Training

Sign up:

Sign up: