Development begins on next-gen batteries for sustainable vehicles

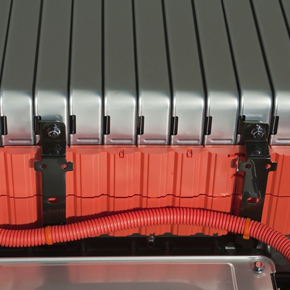

Resource recovery specialist Axion Consulting has joined a consortium created to help develop the next generation of traction batteries for electric and hybrid vehicles.

The £14 million project is led by WMG at the University of Warwick and will create an automotive battery pack manufacturing research centre.

The centre will combine human and automated assembly methods to manufacture battery packs and lay the foundations o a new UK automative supply chain based around the technology.

Axion will help to develop the lifecycle management of the new battery system, including its recycling, remanufacturing and/or repurposing at the end of its lifecycle. It will also research processes for recovering high value metal compounds from the batteries.

Axion Senior Engineer, Sam Haig, commented: “This is an exciting new project that allows us to engage with and have valuable input into the whole design process from initial designs to prototyping and manufacturing.

We are proud to be part of the consortium being led by WMG and look forward to working with the other partners to deliver an innovative project on vehicle batteries. There could be potential in the future to extend this type of work to other lithium ion batteries, such as those in laptops and mobile phones.”

AMPLiFII

The project – called AMPLiFII (Automated Module-to-pack Pilot Line for Industrial Innovation) – has received £10 million funding from the UK’s innovation agency Innovate UK.

It will be used to develop new knowledge, skills, technology and facilities to support UK industry seeking to use these new technologies and processes in vehicle battery systems.

The project brings together a number of partners from multiple industries, including: Jaguar Land Rover, JCB, Delta Motorsport, Potenza Technology, The University of Oxford and Ariel Motor Company.

Professor David Greenwood from WMG, at the University of Warwick, said: “This project will create a UK supply chain for fully qualified battery packs to suit hybrid and electric vehicles requiring volumes from hundreds to thousands of units per year. These volumes traditionally do not justify high levels of development cost and effort.

“However by developing and creating a modular battery architecture, based on cylindrical cells for both high power and high energy requirements, the supply chain will be able to aggregate demand for components from many applications and benefit from significant economies of scale. AMPLiFII will create a battery supply chain with mass-production standards of robustness that is high quality, low cost and fast to market.”

Once the project has been completed, the pilot line will become an open facility at WMG that will operate alongside the national cell scale-up facility already at WMG, and part of the “Electrical Energy Storage” Spoke of the APC.

Axion

Tenax Road

Trafford Park

Manchester

M17 1JT

Visit Supplier's page

Latest news

29th April 2025

Senior pledges to ‘bee’ part of the solution with new biodiversity initiative

Senior Architectural Systems has installed its first on-site beehive, marking another step forward in its commitment to sustainability and biodiversity.

Posted in Articles, Building Industry News, Building Products & Structures, Building Services, Curtain Walling, Doors, Glass, Glazing, Innovations & New Products, news, Restoration & Refurbishment, Retrofit & Renovation, Sustainability & Energy Efficiency, Walls, Windows

29th April 2025

West Fraser range delivering key benefits for South-East carpentry company

An experienced carpenter and building site manager who has recently set up his own company is using high performance panel products from the West Fraser range.

Posted in Articles, Building Industry News, Building Products & Structures, Building Systems, Case Studies, Garden, Restoration & Refurbishment, Retrofit & Renovation, Sustainability & Energy Efficiency, Timber Buildings and Timber Products

29th April 2025

CPD Courses Available Online From Ecological Building Systems

Ecological Building Systems, a leading supplier of natural building products for sustainable construction, has revealed its comprehensive CPD programme for the year ahead.

Posted in Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Continuing Professional Development (CPD's), Information Technology, Innovations & New Products, Insulation, Restoration & Refurbishment, Retrofit & Renovation, Seminars, Sustainability & Energy Efficiency, Training, Walls, Waste Management & Recycling

29th April 2025

WindowBASE launches new prospect databases at FIT Show

Visit WindowBASE at the FIT Show to see first-hand how it helps companies find new customers – the company is launching an easy-to-use, intuitive platform on Stand G16 at the NEC Birmingham from 29th April – 1st May.

Posted in Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Doors, Exhibitions and Conferences, Glass, Glazing, Information Technology, Innovations & New Products, Posts, Publications, Research & Materials Testing, Restoration & Refurbishment, Retrofit & Renovation, Windows

Sign up:

Sign up: