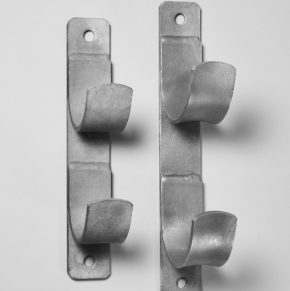

Ellis improves on its tried, tested and trusted cable hangers

Ellis has enhanced a product that has been one of its best-sellers for over 20-years, making its cable hangers stronger and, remarkably, cheaper.

Stephen Walton, Ellis’ technical director, comments: “With the market for cable hangers growing, and the number of extremely similar products also expanding, it was felt we needed to improve on the design in order to capitalise on new opportunities, while at the same time protecting our current customer base.”

Ellis achieved this by looking at every aspect of the product and looking at ways to improve on it. The first key development is that there are two different versions of the new Ellis cable hanger – a standard Mk2 cable hanger, and a convex hanger; the latter designed specifically for use in tunnels, where the mounting surface is often curved.

The new Mk2 cable hangers feature rounded corners, to avoid snagging points, are available in a wide range of sizes and custom designs, and are available in rolled designs for tunnels. Plus, they are spin galvanised to protect against erosion, are suitable for cables up to 100mm in diameter, and are only 6mm thick, leading to reduced product and shipping costs.

Meanwhile, the convex cable hanger has all the benefits of Mk2, as well as having no sharp edges presented to the cable by tradition hangers, and being the same strength as the Mk2 whilst only being 5mm thick.

Stephen adds: “To take a product that to all intents and purposes was a commodity product, and redesign it in a manner that makes it not only better, but also cheaper and stronger than anything else on the market goes to show the commitment we have at Ellis to not just sell cable cleats and cable hangers, but to sell the very best.”

Ellis’ in-house capability covers everything from product design to prototype production; testing to manufacture. It also holds its own product stock and manages all deliveries.

Latest news

5th February 2025

Elevating safety and accessibility at Yeomanry Close with Stannah Lifts

A new lift system by Stannah at Yeomanry Close in Warwickshire not only meets standards, but also includes features that ensure a safer, more accessible and comfortable experience for residents, supporting their mobility and independence.

Posted in Accessibility, Articles, Building Industry News, Building Products & Structures, Building Services, Case Studies, Facility Management & Building Services, Health & Safety, Interiors, Lifts, Posts, Restoration & Refurbishment, Retrofit & Renovation

4th February 2025

Delta Membranes: An Education in Waterproofing

As proud members of the RIBA CPD Providers Network, Delta Membranes can offer its CPDs as double point RIBA Accredited.

Posted in Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Regulations & Accreditations, Building Services, Continuing Professional Development (CPD's), Damp & Waterproofing, Facility Management & Building Services, Information Technology, Restoration & Refurbishment, Retrofit & Renovation, Seminars, Training

4th February 2025

Wetherby Wall Systems: Guiding the Industry Through Gateway 2 Compliance

As the construction sector adapts to the UK’s Building Safety Act 2022, Wetherby Wall Systems, part of the ROCKWOOL Group, is positioned to support industry professionals in navigating the new regulatory landscape.

Posted in Articles, Building Industry News, Building Products & Structures, Building Regulations & Accreditations, Building Services, Building Systems, Cladding, Facades, Facility Management & Building Services, Insulation, Posts, Restoration & Refurbishment, Retrofit & Renovation, Security and Fire Protection, Walls

3rd February 2025

Senior takes the lead on sustainability with new appointment

Senior Architectural Systems, the UK’s largest privately-owned manufacturer of aluminium windows, doors, and curtain walling, has appointed Luke Osborne to the newly created role of UK sustainability lead.

Posted in Aluminium Products, Architectural Ironmongery, Articles, Building Industry News, Building Products & Structures, Building Regulations & Accreditations, Building Systems, Doors, Recruitment, Restoration & Refurbishment, Retrofit & Renovation, Sustainability & Energy Efficiency, Windows

Sign up:

Sign up: