Engineering excellence – an article from Ketley Brick

Dr. Geoff Edgell, Director and Principal Construction Consultant, at Lucideon outlines the critical performance characteristics of engineering bricks and highlights the importance of selling products that are truly fit for purpose for the application.

“Engineering bricks are part of our heritage. Anyone who travels the country will be familiar with the use of Accrington NORI bricks in the north, and Staffordshire Blues in the midlands and southern parts of the country, especially in railway and canal works.

It may come as a surprise to some that in 1946 there was a British Standard for clay engineering bricks; ahead of that for other brick types. The original standard defined Classes A and B by water absorption and compressive strength, which is still used today.

The latest British Standard does not include a classification for engineering bricks and uses the European terminology of clay masonry units as it covers units in a wide range of sizes and perforation levels from around Europe.

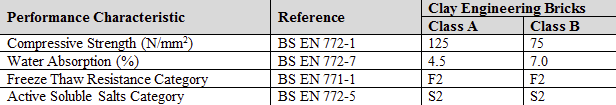

This is largely to avoid an extensive range of definitions, including Klinker and Canal bricks, which are essentially similar products from other countries. Clay engineering bricks are referred to in the National Annex, which is informative and not mandatory, however the given properties can be found in the table below:

Moving forward — as our guidance documents refer less and less to these traditional products, other than in drainage and sewerage applications — and where will the Class A engineering brick feature? The future is surprisingly interesting as both climate change and architectural trends are leading to situations where the characteristics of Class A engineering bricks are ideally suited.

For a decade or so, the government has been describing strategies to avoid flood damage and minimise disruption to homeowners. The key elements are now incorporated in BS 85500: Flood Resilient and Resilient Construction — Guide to Improving the Flood Performance of Buildings, which was published in 2015.

The key elements are the concepts of:

- Avoidance – basically build to avoid flooding

- Resistance – prevent water entry

- Resilience – entry occurs, but the impact is low and drying and cleaning are facilitated

- Repairable – elements that are damaged are easily repaired or replaced.

Some research into the performance of materials was carried out at HR Wallingford and the research provided encouraging results for Class A engineering bricks. A variety of common building materials, including bricks, blocks, timber boards and plasterboard, were subjected to a static level of 1m of water of applied to the face for three days.

The rate of seepage through the face and the rate at which the materials dried out were monitored. No seepage occurred through the Class A engineering brick, which was the only material tested which demonstrated complete resistance to seepage. Naturally, as the bricks took up so little water they were the best at drying out. Tests on cavity walls confirmed this performance, although of course, there was some leakage into the cavity through the mortar joints.

Overall, the resilience rating of engineering bricks achieved the top rating of good (in a good, medium and poor traffic light rating scheme). This is very encouraging as the government considers the development of standards and certification in relation to flood resilience in the light of the Bonfield Review: The Property Flood Resilience Action Plan which was published in September 2016.

Brickwork is experiencing something of an architectural renaissance and numerous buildings are using textured facades and ‘lattice’ or ‘hit and miss’ brickwork. Part of this revival can be attributed to the increase in prefabricated panels where complex details can be achieved, and whole panels transported to site for incorporation in the building.

As a direct consequence of projecting bricks from the face of the wall to provide texture, some of the bed face of the unit is exposed to the weather. This situation can lead to the exposed part of the brick being exposed to omni-directional freezing and thawing, as opposed to the uni-directional action when in a plain wall façade.

There is insufficient knowledge about the conditions and research is in hand, however it is clear that products that are equally suitable for brickwork and paving applications, such as Class A engineering bricks, must have the appropriate characteristics to resist frost attack.

Clearly the two areas described, flood resilience and building façade design, are going to be on the popular agenda for years to come. It is very encouraging that a traditional product such as the Class A engineering brick can immediately demonstrate its fitness for purpose and potentially contribute to our heritage for generations to come.”

This article was arranged in consultation with Ketley Brick.

Telephone: 01384 78361

Fax: 01384 74553

Email : sales@ketley-brick.co.uk

Visit Supplier's page

Latest news

28th April 2025

Nuaire first UK ventilation manufacturer to use low carbon-emissions recycled & renewably produced steel

Nuaire has announced that its Magnelis® steel based ventilations systems are now being made from XCarb® recycled and renewably produced steel.

Posted in Air Conditioning, Articles, Building Industry News, Building Products & Structures, Building Services, Building Systems, Heating, Ventilation and Air Conditioning - HVAC, Restoration & Refurbishment, Retrofit & Renovation, Steel and Structural Frames, Sustainability & Energy Efficiency, Waste Management & Recycling

28th April 2025

Renderplas: Builders avoid costly remedial work with PVCu render beads

A pioneer of PVCu render beads, Renderplas is helping the construction industry avoid the costly remedial work associated with rusting steel designs…

Posted in Articles, Building Industry News, Building Products & Structures, Building Services, Building Systems, Facades, Posts, Render, Restoration & Refurbishment, Retrofit & Renovation, Sustainability & Energy Efficiency, Walls

28th April 2025

How Celotex’s Technical Team adds value through expert insulation support

From U-value calculations to real-world installation support, Celotex’s technical team helps construction professionals specify and install insulation with confidence…

Posted in Articles, Building Industry News, Building Products & Structures, Building Services, Insulation, Research & Materials Testing, Restoration & Refurbishment, Retrofit & Renovation, Sustainability & Energy Efficiency, Walls

28th April 2025

Ideal Heating Commercial takes extra care with the heat network at Huddersfield specialist housing development

Ideal Heating Commercial POD Heat Interface Units (HIUs) and Evomax 2 condensing boilers have been installed into Ash View Extra Care in Huddersfield.

Posted in Articles, Building Industry News, Building Products & Structures, Building Services, Case Studies, Facility Management & Building Services, Heating Systems, Controls and Management, Heating, Ventilation and Air Conditioning - HVAC, Pipes & Fittings, Plumbing, Restoration & Refurbishment, Retrofit & Renovation

Sign up:

Sign up: