Green Omega recycling installers help Armstrong Ceilings to record heights

Armstrong Ceilings has broken its recycling records for the second year running, thanks to its rapidly expanding network of Green Omegas (specialist sub-contractors with specialist recycling expertise).

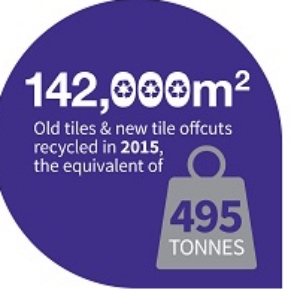

The ceiling manufacturer announced that it recycled a total 142,000m2 of material last year, during which time nine of its 136 member Omega network qualified as Green Omegas. The total amount recycled equates to 495 tonnes (or more than 528 skips), which would have cost contractors almost £100,000 in landfill tax.

All recycled material has been returned for use in the manufacture of new mineral ceiling tiles, saving the company more than £28,000 in virgin materials.

Green Omegas

Not only is the recycling scheme saving contractors money, but the Green Omega accreditation is also making them more money.

Installers PFP, based in Edinburgh, have been in business since 1997 and an Armstrong Omega since the millennium while CAP Ceilings and Partitions, based in Exeter, have been in business since 2002 and an Omega since then.

PFP managing director Boyd Sinclair said of the Omega scheme: “The benefits of becoming an Omega installer were the closer working relationship with Armstrong, PFP being recommended to clients by Armstrong for projects, and receipt of project leads from Armstrong.

“We can project ourselves better as a reputable installer of Armstrong products which is of particular benefit when we are competing against labour only sub-contractors as we do come across a number of main contractors trying to weigh up the choice between buying materials direct and using labour-only sub-contractors (self-employed operatives) versus ourselves to procure and install the materials.

“Most labour-only sub-contractors would not be Armstrong Omega certified and so if we can demonstrate to the main contractor that we are a certified installer and a Green one at that this makes a difference. It makes a difference too against those of our competitors who are non-Omegas. It just gives us a bit of an edge against the competition (albeit some main contractors are only looking for the cheapest price).”

PFP became a Green Omega last year on completion of their biggest Armstrong project to date – the Queen Elizabeth University Hospital in Glasgow – where 10,000m2 or 35 tonnes of mineral ceiling tile off-cuts were recycled over the two years for main contractor Brookfield Multiplex.

Gary Mortimer, project surveyor for PFP, said then: “The sheer size and complexity of this project could have made it an extremely challenging one but the recycling element, particularly with Skipeez on board, went very smoothly. We had never used such a variety of Armstrong systems before on one project but thanks to the level of support we received from Armstrong’s local sales and technical teams and the distributor, we managed to deliver a project we are all very proud of.”

CAP, who had recycled plasterboard walls before, also became a Green Omega last year after recycling 7,000m2 of old tiles and new tile off-cuts from an office block in Bristol for main contractor Midas.

Director Gary Rice said of that: “It was a very tight, congested site so the logistics were challenging.”

Of the Green Omega scheme, PFP’s Boyd Sinclair said: “It is definitely worthwhile getting involved. It provides us as a sub-contractor with a very easy route to recycling our off-cuts. It also allows us to add another element to our recycling strategy as we also currently recycle our plasterboard waste on a number of projects.

“Armstrong are streaks ahead of the competition when it comes to their commitment to recycling mineral ceilings within the industry. They have ensured that their distribution partners (our suppliers) are fully on board with the scheme and this allows us to work as a team to ensure waste is diverted from landfill.

“As more and more main contractors are becoming increasingly environmentally conscious working with Armstrong allows us to present this as a selling point to the client which places Armstrong’s products ahead of the competition and gives us an edge over the competition. At this stage it isn’t easy to quantify the benefits, especially not in terms of turnover, but it is definitely a strong advantage and selling point for everyone involved in the scheme.”

Gary Rice added: “The benefits of being an Omega member are the recognition, being a recommended installer of the market leader. The support from Armstrong has certainly helped us to grow the business from ground zero to £8 million.”

And of being a Green Omega, he said: “We are very conscious of our environmental impact so it helps us with that and it helps that we can demonstrate that to our clients. We are looked upon more favorably by clients because we have the recycling system in place.

“It’s a no brainer as there are no cost implications but it helps us with cost reduction to a certain point in that we can monitor our waste more and also know that hopefully when the tiles go back in it helps to bring down the cost of new tiles.”

Of the future for ceiling recycling, PFP’s Boyd Sinclair said: “The momentum needs to be kept up although with the size of Armstrong as a global player and their commitment to drive this through as a USP for their business this should not be a problem.

“The challenge, which is also an opportunity, is to get more sites taking advantage of the scheme as some main contractors are more conscientious than others. It really comes down to Armstrong and the Green Omegas spreading the word. Commonly when it works on one site that site team/company take the system/process forward to the next one and before long it is the norm or is incorporated into the way they run their sites. So with time it should become common practice.”

CAP’s Gary Rice added: “It is making main contractors aware that this is available to them and that we are able to help with that. I think Armstrong have done a good job of covering it off – they are even taking other manufacturer’s ceiling tiles back now. As for the future, perhaps recycling of the grid systems should be next on the agenda and more ways of using off-cuts actually on site, perhaps for additional acoustic flanking.”

The other Armstrong Omegas to become Green Omegas last year are Dancor, DV McColl, East Midlands Ceilings, Eastledge, ISEC, Oatley Ceilings and Richard Kemble.

Contact:

Armstrong World Industries Limited

Harman House,

2nd Floor,

1 George Street,

Uxbridge UB8 1QQ

0800 371849

email: Sales-support@armstrong.com

Visit Armstrong Ceiling's website

Visit Supplier's page

Latest news

17th April 2025

Nuaire shares expertise at Specifi Mechanical Services events in 2025

Indoor air quality and ventilation manufacturing specialist Nuaire is pleased to be exhibiting at the Specifi Mechanical Services events once again in 2025.

Posted in Air Conditioning, Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Exhibitions and Conferences, Facility Management & Building Services, Heating, Ventilation and Air Conditioning - HVAC, Restoration & Refurbishment, Retrofit & Renovation

15th April 2025

West Fraser: CaberDek earns top marks from Home Counties carpentry specialist

A specialist carpentry sub-contractor covering housing sites across a large swathe of the Home Counties has come to value CaberDek from the West Fraser range for a variety of reasons: not least because the high quality panel product doesn’t destroy his operatives’ electric saws!

Posted in Articles, Building Industry News, Building Products & Structures, Building Systems, Case Studies, Restoration & Refurbishment, Retrofit & Renovation, Roofs, Timber Buildings and Timber Products, Wooden products

15th April 2025

GEZE: The Role of Access Control Systems in Enhancing Building Safety

Jane Elvins, Specification and Business Development Manager at GEZE UK, delves into the role of access control systems in enhancing building safety…

Posted in Access Control & Door Entry Systems, Architectural Ironmongery, Articles, Building Industry News, Building Products & Structures, Building Services, Doors, Facility Management & Building Services, Health & Safety, Restoration & Refurbishment, Retrofit & Renovation, Security and Fire Protection

11th April 2025

Don’t Do a Dave! It’s Time to Lock FIT Show 2025 in Your Calendar!

It’s that time again – FIT Show is back! You could be forgiven for thinking there won’t be much new to see when FIT Show returns to the NEC from 29 April – 1 May. Wrong!

Posted in Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Continuing Professional Development (CPD's), Exhibitions and Conferences, Information Technology, Innovations & New Products, Restoration & Refurbishment, Retrofit & Renovation, Seminars, Training

Sign up:

Sign up: