Historic indoor market transformed with Contour column casings

Kirkgate Market in Leeds is one of Europe’s largest indoor markets, with a rich history stretching back to the early 19th century. It has recently undergone a £13.7m refurbishment undertaken by Leeds City Council which included the specification of bespoke column casings from Contour.

The column casings were specified as a key part of the transformation to the ‘1976’ Hall, which has been turned into a unique central meeting point for shoppers. The 4.5 metre high casings encircled floor to roof I-beams and were positioned above four catering units in the hall.

An effective combination of function and form, the casings safely housed a large array of power conduits, water pipes and ventilation ducting whilst presenting an attractive external appearance thanks to an individual 30% gloss RAL colour coating.

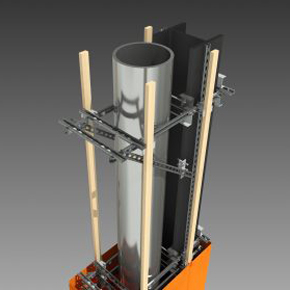

Unistrut frames and Contour column casings

The roofs of the catering units were effectively non-weight bearing and therefore could not be used to support the column casings. Furthermore, there was no guarantee that the hall roof would be strong enough to support the weight of the casings without time consuming and costly static load testing.

Interserve, the lead project contractors, therefore turned to Contour for a solution which would see the casings suspended by some other means.

Interserve, the lead project contractors, therefore turned to Contour for a solution which would see the casings suspended by some other means.

Contour developed a bespoke system of attaching the casings to the I-beams which did not involve drilling or affecting the structural integrity of the beams using a Unistrut frame. The frame was clamped to the I-beam to support the column casing, with a further cantilever arm attached to ensure that the frame did not bend, distort or slip down the beam once the weight of the casing was fully applied.

Importantly, force calculations were undertaken to determine the exact length of the cantilever arm and its angle of attachment. During the load tests, Contour subjected a single supporting frame to weights in excess of 100kgs. The frame system easily passed the testing process, meaning the installation could proceed in full confidence.

The column casings themselves were manufactured from 3mm aluminium sheet to provide strength, rigidity and lightness. To allow for the pipework and ducting to run through, each casing required numerous cuts out that were programmed during manufacture to minimise on-site cutting.

Latest news

15th April 2025

West Fraser: CaberDek earns top marks from Home Counties carpentry specialist

A specialist carpentry sub-contractor covering housing sites across a large swathe of the Home Counties has come to value CaberDek from the West Fraser range for a variety of reasons: not least because the high quality panel product doesn’t destroy his operatives’ electric saws!

Posted in Articles, Building Industry News, Building Products & Structures, Building Systems, Case Studies, Restoration & Refurbishment, Retrofit & Renovation, Roofs, Timber Buildings and Timber Products, Wooden products

15th April 2025

GEZE: The Role of Access Control Systems in Enhancing Building Safety

Jane Elvins, Specification and Business Development Manager at GEZE UK, delves into the role of access control systems in enhancing building safety…

Posted in Access Control & Door Entry Systems, Architectural Ironmongery, Articles, Building Industry News, Building Products & Structures, Building Services, Doors, Facility Management & Building Services, Health & Safety, Restoration & Refurbishment, Retrofit & Renovation, Security and Fire Protection

11th April 2025

Don’t Do a Dave! It’s Time to Lock FIT Show 2025 in Your Calendar!

It’s that time again – FIT Show is back! You could be forgiven for thinking there won’t be much new to see when FIT Show returns to the NEC from 29 April – 1 May. Wrong!

Posted in Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Continuing Professional Development (CPD's), Exhibitions and Conferences, Information Technology, Innovations & New Products, Restoration & Refurbishment, Retrofit & Renovation, Seminars, Training

11th April 2025

Insight Data: Boost construction success with project and prospect data

For those working in construction – in whatever capacity – the last few years haven’t been much fun. And according to the latest statistics, it would seem the challenges are continuing – Alex Tremlett, Insight Data’s Commercial Director, has more…

Posted in Articles, Building Industry News, Building Services, Information Technology, news, Research & Materials Testing

Sign up:

Sign up: