How cement particle floorboards work – Hush CEM 28 overview

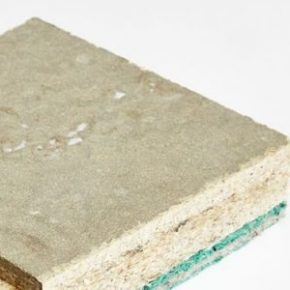

Hush Panel CEM 28 is Hush Acoustics‘ exceptional high mass acoustic floorboard, made from cement particle board and covered with its exclusive Hush Felt 10mm resilient layer.

The particle board is made up of both chipboard and cement, specially mixed together to create the denseness required to tackle both impact and airborne sound performance within modern and lightweight structures.

Applying acoustic resilient layers

Hush felt is a hard wearing, environmentally friendly, manufactured from recycled fibres and is unique to Hush. These recycled fibres are knitted together through needle punching, which is a high-tech method used to establish the thickness of the product, contributing to the endurance of the acoustic floor. Adding to its incomparable resilience, Hush felt also has a rot proof polypropylene layer.

What are cement particle floorboards used for?

Hush Panel CEM 28 was designed to meet the requirements to achieve legislation on site and guarantee performance criteria within contemporary construction.

Contemporary construction such as new build timber frame, cross laminated timber, steel frame buildings, offsite or modular construction is categorised as lightweight due to the frames generally being made from wood or steel.

By adding high amounts of mass to the lightweight constructions, the airborne and impact noise performance is increased, something that does not occur when using only a standard acoustic flooring.

How to install

The tongue and groove design of the board makes for quick and easy installation due to its interlocking edges, adding to a stable floor surface to carry many floor finishes.

Used to achieve Building Regulations in the UK, inclusive of Document E compliant (England & Wales), Section 5 compliant (Scotland), Part G compliant (Northern Ireland) and also used to exceed minimum performance criteria of the Building Regs for planning approval or BREEAM, along with being a robust details compliant system or achieving Robust Details performance standards, Hush CEM 28 makes for an excellent choice for high rise buildings, such as flats and hotels and is also ideal for modular and offsite construction projects.

This product is a direct alternative to other dry screed board products on the market and will achieve the same acoustic performance.

Along with the whole host of benefits already described, the Hush CEM Panel 28 also holds a Class O fire rating, which is highly fire retardant, meeting building fire regulations.

Hush CEM Panel 28 has been tested for its Acoustic performance and the measure of effectiveness is shown in decibels (dB). The higher the transmission loss, the better the barrier to the passage of unwanted noise.

Hush Acoustics Ltd

Unit 2, Tinsley Industrial Estate

Shepcote Way

Sheffield

South Yorkshire

S9 1TH

Tel: 0114 551 8685

Fax: 0151 944 1146

Visit Supplier's page

Latest news

28th March 2025

Ideal Heating Commercial announces 10-year warranty on Evomax 2 boiler

Evomax 2, the UK’s number one selling commercial wall-mounted boiler from Ideal Heating Commercial, is now available with a 10-year warranty.

Posted in Articles, Building Industry News, Building Products & Structures, Building Regulations & Accreditations, Building Services, Facility Management & Building Services, Heating Systems, Controls and Management, Heating, Ventilation and Air Conditioning - HVAC, Innovations & New Products, Pipes, Pipes & Fittings, Plumbing, Retrofit & Renovation, Sustainability & Energy Efficiency, Videos

28th March 2025

FLIR Si1-LD Acoustic Imaging Camera for Compressed Air Leak Detection

FLIR, a Teledyne Technologies company, introduces the Si1-LD, an industrial acoustic imaging camera that brings faster and more accurate compressed air leak detection to those operating on a modest condition monitoring budget.

Posted in Acoustics, Noise & Vibration Control, Articles, Building Industry News, Building Products & Structures, Building Services, Facility Management & Building Services, Information Technology, Innovations & New Products, Retrofit & Renovation, Sustainability & Energy Efficiency, Thermal Imaging and Monitors

28th March 2025

LIFTEX 2025 Seminar programme announced

Registration has opened for LIFTEX 2025. Now in its 37th year, LIFTEX 2025 is the UK’s only dedicated exhibition for the lift, escalator and access industry and takes place only once every three years.

Posted in Access Control & Door Entry Systems, Accessibility, Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Regulations & Accreditations, Building Services, Exhibitions and Conferences, Facility Management & Building Services, Health & Safety, Retrofit & Renovation, Security and Fire Protection, Seminars

28th March 2025

MCRMA welcomes ArcelorMittal UK to membership

A UK division of the global steelmaking business ArcelorMittal has become the latest new member of the MCRMA, the industry association representing the metal building envelope sector.

Posted in Articles, Building Associations & Institutes, Building Industry News, Building Products & Structures, Building Systems, Cladding, Facades, Posts, Restoration & Refurbishment, Retrofit & Renovation, Roofs, Steel and Structural Frames, Walls

Sign up:

Sign up: