How does powder coating stick to wood?

Many manufacturers are choosing to enhance the aesthetic appeal of their wooden products by powder coating them. However, as wood does not usually respond well to heat, people have asked how powder coating sticks to it.

According to PB Metal Finishing Systems, there are three key elements in effective powder coating: selecting the right type of wood, applying the heat correctly and charging the powder.

A guide to powder coating

Choosing the right wood

As it comprises an engineered board of compressed, assorted adhesives, wood fibres and resins, medium density fibre wood (MDF) has been deemed the most suitable for powder coating by researchers.

It has the right moisture content and bond strength to generate an electric current and make the powder coating stick.

Heat application

To begin the powder coating process, the wood board must conduct an electric current.

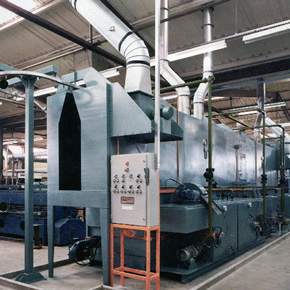

In order to draw the moisture to the surface of the wood, the board is heated to a high temperature, relatively quickly, in an industrial oven. Such appliances are supplied by PB Metal Finishing Systems in a range of sizes and temperatures, varying from 50°C to 500°C.

Once the board has been sprayed, it is heated for a second time to ensure that the powder bonds to the wood.

Charging the powder

After the heated MDF has conducted an electric current, it can be powder coated. Two different power materials are available: UV-cured and thermal cure.

UV-curable powders require minimum heat. Once the coating has been applied to the wood, the parts are inserted into a convection oven, where the coating is left to melt for between two and ten minutes.

The board is then exposed to an ultraviolet light for several seconds to allow the finish to harden. Finally, the parts are left to cool.

For thermal cure powders, ovens which combine infrared and convection heating are required. The powder is melted by the thermal energy that is produced; this allows it to flow into a level film and cure or crosslink into a finished film. Again, minimal heat is required for curing.

Latest news

24th February 2025

Victaulic solutions enable record-time piping system installation at Manchester's newest office block

Victaulic, a global leader in mechanical pipe joining, has played a key role with its innovative solutions in the development of Plot 9A, a cutting-edge 10-storey office block located on First Street in Manchester.

Posted in Articles, Building Industry News, Building Products & Structures, Building Services, Case Studies, Drainage, Drainage, Guttering, Soffits & Fascias, Facility Management & Building Services, Pipes, Pipes & Fittings, Plumbing, Restoration & Refurbishment, Retrofit & Renovation, Sustainability & Energy Efficiency

24th February 2025

Safeguard: Redecorate after disaster with Dryzone Damp & Stain Seal

Make your living space feel like home again with Safeguard Europe’s Dryzone Damp & Stain Seal – a high-performance stain blocking paint for interiors.

Posted in Articles, Building Industry News, Building Products & Structures, Building Services, Ceilings, Damp & Waterproofing, Facility Management & Building Services, Interior Design & Construction, Interiors, Paints, Paints, Coatings & Finishes, Restoration & Refurbishment, Retrofit & Renovation, Walls

24th February 2025

Vent-Axia Launches Smart High-Speed Hand Dryer

Vent-Axia has launched the next generation of hand dryer with its Tempest SmartDry high-speed hand dryer. Ticking all the right boxes for a premium hand dryer, the Tempest SmartDry is designed with a built-in HEPA filter, antimicrobial cover, and patented noise-cancelling technology.

Posted in Air Conditioning, Articles, Building Industry News, Building Products & Structures, Building Services, Facility Management & Building Services, Heating, Ventilation and Air Conditioning - HVAC, Innovations & New Products, Restoration & Refurbishment, Retrofit & Renovation

24th February 2025

Hush: Maximising acoustic insulation in floating floors

Hush Acoustics offers acoustic insulation solutions for all types of floating floors to help create quieter, more comfortable homes and acoustically superior non-domestic buildings.

Posted in Acoustics, Noise & Vibration Control, Articles, Building Industry News, Building Products & Structures, Building Services, Facility Management & Building Services, Floors, Insulation, Restoration & Refurbishment, Retrofit & Renovation

Sign up:

Sign up: