How new RdSAP helps tackle uninsulated party wall cavities

Tackling heat lost through uninsulated party wall cavities in existing homes

Knauf Insulation welcomes new RdSAP (version 9.92) which follows new research headed by Leeds Beckett University (formerly Leeds Metropolitan University), MIMA (the Mineral Wool Insulation Manufacturers’ Trade Association) and Knauf Insulation.

New research findings include:

- significant amount of heat is lost through uninsulated cavity party walls

- in modern houses the heat loss into the party cavity walls could be as much as that from all other elements combined

Party wall thermal bypass

Knauf Insulation on the role of party wall insulation in preventing heat loss

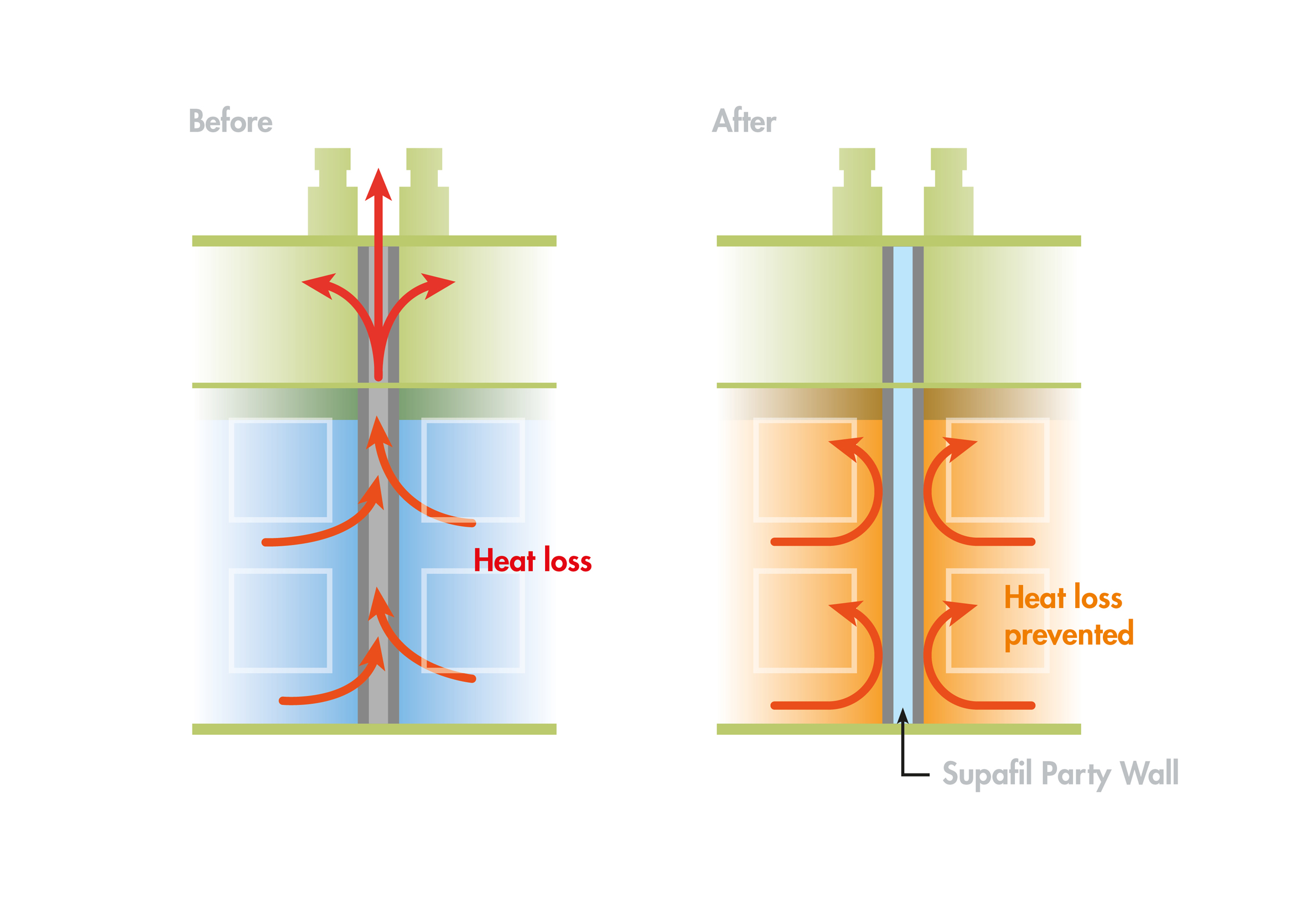

In external walls, heat is mainly lost due to conduction through the wall, as the heat passes through the various material layers. In party walls, heat loss occurs through a phenomenon known as party wall thermal bypass.

Party wall thermal bypass

- occurs where cold air enters the uninsulated cavity at exposed edges

- cavity creates a chimney effect and the cold air rises as it is warmed by heat conducted through the leaves of the party wall from the adjoining homes, before into the loft space or through the roof

Semi detached and terraced houses built in the last 65 years have generally been constructed with a cavity party wall and it was only in 2010 that the building regulations recognised the effect in new build dwellings. So all houses with party cavity walls built to earlier regulations are likely to require remedial treatment to eliminate the heat loss.

Over 7 million homes in the UK lose heat through untreated cavity party walls

The research that helped to identify the problem also demonstrated that party wall thermal bypass could be prevented by fully filling the empty party wall cavity with mineral wool, providing a significant opportunity to improve the energy efficiency of buildings at relatively low cost.

Over 5 million of the untreated party wall cavities have a full cavity from ground level all the way to the underside of the roof thus increasing the amount of heat lost compared to the remaining party cavity walls, which have a solid section to the underside of the roof.

What are the savings if all of the full party wall cavities were treated?

- approximately £465 million per year

- 2.5 million tonnes of CO2 [1]

That is equivalent to:

- carbon generated by one person taking 2.5 million return flights to New York

- or driving 5 billion miles in a four wheel drive car

- or travelling 27.5 billion miles on national rail [2]

Stephen Wise, Technical Development Manager at Knauf Insulation:

The inclusion within RdSAP 9.92 is great news, as it shows that the problem of party wall thermal bypass is being taken seriously, but it does mean there is some work to be done now to improve understanding of the issue within the industry.

As it is a relatively low cost measure with a short payback period this will also mean that party wall insulation will be able to attract funding under the current Energy Company Obligation, and is classed as a primary measure under the scheme. The industry now needs to ensure that assessors are properly trained to identify heat loss cavities and that installers are trained and equipped to install the treatment required.

Since 2005, we have been working with a number of organisations, including Leeds Beckett University who are experts in building physics, to understand the mechanisms of party wall bypass and develop solutions to adequately eliminate it. Through this research we have learned a great deal including how to identify if a party wall has a cavity and whether it is suitable for insulating.

We have also found how to overcome non-standard homes where installation will differ to standard external cavity wall insulation methods. Most importantly however, we have gathered solid evidence that our Supafil Party Wall solution, specifically developed to insulate party cavity walls, provides a reliable means of eliminating party wall bypass without compromising the acoustic performance of the wall something that is highly important if this is to see uptake on a large scale to help reduce energy bills throughout the country.

We are now looking to share our knowledge with relevant parties such as energy assessors, housing associations, insulation installers and others – all to ensure the industry is ready to deliver the energy saving measures as required.

LINK TO MORE INFORMATION ON PARTY WALL INSULATION

.

[1] Building Research Establishment (BRE)

[2] Aviation Environment Foundation

Latest news

21st February 2025

ASSA ABLOY EMEIA: Save valuable time and money with a seamless switch to programmable digital keys

In 2025, access management can be a whole lot easier. By making access part of their digital processes, businesses can put time-consuming key management and the cost of changing the locks firmly behind them. Making this switch is a lot easier than many people think, as ASSA ABLOY explains here…

Posted in Access Control & Door Entry Systems, Architectural Ironmongery, Articles, Building Industry News, Building Products & Structures, Building Services, Doors, Facility Management & Building Services, Health & Safety, Information Technology, Innovations & New Products, Retrofit & Renovation, Security and Fire Protection

21st February 2025

Showersave supports industry leaders in addressing Part L and Part G regulations

Showersave has sponsored and participated in a recent Building Insights LIVE roundtable on ‘Water & Energy Saving Innovations in New Build Housing’.

Posted in Articles, Bathrooms & Toilets, Bathrooms, Bedrooms & Washrooms, Building Associations & Institutes, Building Industry Events, Building Industry News, Building Products & Structures, Building Regulations & Accreditations, Building Services, Exhibitions and Conferences, Interiors, Pipes & Fittings, Plumbing, Retrofit & Renovation, Sustainability & Energy Efficiency

21st February 2025

GEZE: The importance of Specifying High Quality Door Closers on Fire Doors

Andy Howland, Sales & Marketing Director at GEZE UK, discusses why specifying high quality door closers on fire doors is important…

Posted in Access Control & Door Entry Systems, Accessibility, Architectural Ironmongery, Articles, Building Industry News, Building Products & Structures, Building Regulations & Accreditations, Building Services, Doors, Facility Management & Building Services, Health & Safety, Posts, Restoration & Refurbishment, Retrofit & Renovation, Security and Fire Protection

21st February 2025

Insight Data achieves ISO9001 recertification with zero non-conformities

Leading industry data specialist, Insight Data, has successfully achieved the prestigious recertification for ISO9001 with zero non-conformities for the fourth consecutive year.

Posted in Articles, Building Industry News, Building Regulations & Accreditations, Building Services, Information Technology, Research & Materials Testing

Sign up:

Sign up: