Hush: How to add acoustic insulation in floors with underfloor heating

To make sure your new underfloor heating system isn’t a big let-down due to poor heat output or unwanted sound transmission between floors, the solution could well be to treat the tops of the timber joists with a cleverly designed resilient layer, as Hush Acoustics explains…

The rapid growth in the popularity of underfloor heating has led to the evolution of a great choice of high quality systems to suit many different types of floor construction.

Understandably, the underfloor heating specification and system choices are most probably going to be led by considerations about heat output, energy efficiency and ease of installation and use – all the practicalities that will be top of the priority list. However, it is important not to forget about another major comfort factor – acoustics.

Sound insulation

Sound insulation is crucially important in the separating floors of connected homes, i.e., flats and apartments, to reduce unwanted noise between properties. And there are, of course, minimum acoustic performance levels for separating floors stipulated in the Building Regulations of all four UK nations to help protect us so we can live in our homes in peace and quiet.

But it is not just domestic properties where we need to consider sound reduction measures in separating floors. Perhaps your project is a hotel, office building or educational facility where delivering a quiet space is key. And remember that schools must, in fact, be constructed to minimum acoustic standards under BB93 so those standards have to be complied with – read more in Hush’s blog here.

Many UK properties – whether residential, commercial or public – are built using timber joists for the structure of separating floors, which is why there are plenty of underfloor heating systems available that will suit this kind of construction. Unfortunately, timber joist floor construction is prone to impact noise problems, like the sound of footsteps on a wooden floor or items being dropped.

So, whilst it is a great idea to add acoustic insulation, you must think carefully or risk issues arising with the finished floor or performance of the heating system itself.

Why overlaying acoustic boards may not work…

One of the most popular products manufactured by Hush Acoustics is the Hush-Panel 28 acoustic flooring board. This is often used to create a floating floor with enhanced acoustic properties, which it achieves through a combination of a high quality chipboard in combination with a resilient layer bonded to the underside – Hush-Felt. This is very effective in reducing impact noise transmission in standard timber floor constructions.

But with underfloor heating, the board’s continuous resilient layer will be a problem as it acts as a thermal insulation layer, blocking heat transmission. The result will be to reduce the amount of warmth transferring from the heating system’s pipes to the floor level – not what you will want from your new underfloor heating system by any stretch of the imagination!

Hush-Panel 28 could be suitable for use as a board on which underfloor heating systems can sit on top of. Systems such as those manufactured using insulation with pipes cut into it, or systems which consist of a timber flooring board such as P5 chipboard with the pipes cut into it, can all sit on top of the Hush Acoustic Flooring, such as Hush Panel 28. In these systems, the resilient layer will not impact on heat transmission.

Joist strips offer a simple solution for underfloor heating that is placed between the joists

The purpose of Hush-Panel 28’s resilient layer is to separate the timber board and the joist. So why not think differently and instead apply the resilient layer only where the board and joists connect on top of the joists?

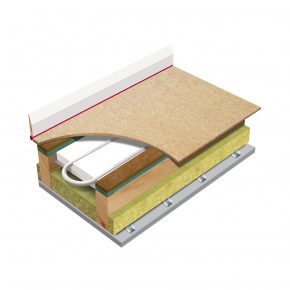

This is the principle behind Hush-Felt 25 joist strips. These are purpose-designed as a joist treatment comprising a 140mm x 50mm hardboard slat fixed to a double layer of 10mm Hush-Felt resilient material. They are stapled to the tops of timber joists, with the integral hardboard slats presenting a firm, smooth surface to support a choice of chipboard, OSB or plywood tongue and groove flooring boards.

By having a resilient layer only on the tops of the joists the heat from the underfloor heating pipes that are placed between the joists can rise through the majority of the floor construction as planned and heat the room – yet impact noise is reduced significantly.

Hush Felt might not be practical in some domestic upgrades or refurbishments due to height build up so one of the other joist strip products available from Hush Acoustics could provide an alternative solution.

These include Hush-10 joist strip, a 10mm thick, 50mm wide resilient strip supplied in lengths of 1.37m which can be stapled to the tops of joists with ease. With compression, the strip thickness will reduce to 8mm so the chosen floor finish will need to account for this.

Another option is to use Hush Isolation Tape. This self-adhesive tape is primarily designed for use beneath internal partitions or for perimeter isolation when installing the Hush systems, but it can also be useful in certain underfloor heating applications. The same applies to Hush Resilient Seatings – load bearing rubber strips that isolate timber joisted construction effectively, as well as masonry construction and metal beam construction.

Speak to acoustics experts to get the best solution

Acoustically insulating a floor featuring underfloor heating is easily achievable once you understand the solutions available and how best to apply them. This is where Hush Acoustics can help.

We have been manufacturing high quality acoustic insulation products for more than 30 years here in the UK, with a range of fully tested systems designed for numerous different floor, ceiling and wall constructions, as well as an extensive portfolio of individual products.

Hush Acoustics Ltd

Unit 2, Tinsley Industrial Estate

Shepcote Way

Sheffield

South Yorkshire

S9 1TH

Tel: 0114 551 8685

Fax: 0151 944 1146

Visit Supplier's page

Latest news

28th March 2025

Ideal Heating Commercial announces 10-year warranty on Evomax 2 boiler

Evomax 2, the UK’s number one selling commercial wall-mounted boiler from Ideal Heating Commercial, is now available with a 10-year warranty.

Posted in Articles, Building Industry News, Building Products & Structures, Building Regulations & Accreditations, Building Services, Facility Management & Building Services, Heating Systems, Controls and Management, Heating, Ventilation and Air Conditioning - HVAC, Innovations & New Products, Pipes, Pipes & Fittings, Plumbing, Retrofit & Renovation, Sustainability & Energy Efficiency, Videos

28th March 2025

FLIR Si1-LD Acoustic Imaging Camera for Compressed Air Leak Detection

FLIR, a Teledyne Technologies company, introduces the Si1-LD, an industrial acoustic imaging camera that brings faster and more accurate compressed air leak detection to those operating on a modest condition monitoring budget.

Posted in Acoustics, Noise & Vibration Control, Articles, Building Industry News, Building Products & Structures, Building Services, Facility Management & Building Services, Information Technology, Innovations & New Products, Retrofit & Renovation, Sustainability & Energy Efficiency, Thermal Imaging and Monitors

28th March 2025

LIFTEX 2025 Seminar programme announced

Registration has opened for LIFTEX 2025. Now in its 37th year, LIFTEX 2025 is the UK’s only dedicated exhibition for the lift, escalator and access industry and takes place only once every three years.

Posted in Access Control & Door Entry Systems, Accessibility, Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Regulations & Accreditations, Building Services, Exhibitions and Conferences, Facility Management & Building Services, Health & Safety, Retrofit & Renovation, Security and Fire Protection, Seminars

28th March 2025

MCRMA welcomes ArcelorMittal UK to membership

A UK division of the global steelmaking business ArcelorMittal has become the latest new member of the MCRMA, the industry association representing the metal building envelope sector.

Posted in Articles, Building Associations & Institutes, Building Industry News, Building Products & Structures, Building Systems, Cladding, Facades, Posts, Restoration & Refurbishment, Retrofit & Renovation, Roofs, Steel and Structural Frames, Walls

Sign up:

Sign up: