Hush: How to prevent nuisance creaks in floors with metal web joists

Metal web joists or posi-joists have become a popular choice for floor construction in recent years thanks to the wide range of benefits they offer versus traditional softwood or I-joists, explains Hush Acoustics…

The strength and versatility they offer in a correctly designed and installed floor makes them an obvious choice for domestic and light commercial construction. In addition to being comparatively lightweight, they are ideal for providing longer room spans and require no cutting or drilling on-site when installing services – valuable practical and time-saving advantages.

But for the full benefits to be realised, as with any structural building system or component, a high standard of design and installation is essential. And in the case of metal web joists that means ensuring that the maximum deflection limits and other performance criteria are met to avoid unwelcome creaking when finished floors are walked upon.

Metal web joists actually have the ability to deliver improved acoustic performance in floors versus softwood in respect of reducing the transmission of impact and airborne noise. The issue of creaky floors, however, is another acoustic issue which is often overlooked in this type of floor construction – but one that can be avoided with the right approach.

Creaky floors represent amongst the most common complaints from buyers of new build homes. The real-life experience of homeowners is often at odds with the design and specification intent which would never have set out to result in this problem, yet issues commonly occur – but why?

Designing-out acoustic problems in floors

One of the key reasons why we get creaking problems in floors built using metal web joists is because of deflection. When a floor above the joist is subjected to a load, i.e. when someone walks across it, the floor joist will flex or bend slightly, and a ‘bounce’ will be experienced.

Metal web joists offer a high degree of rigidity which can be far greater than softwood joists, but it is important to ensure they are used with the deflection limits.

The NHBC stipulates that deflection or vibration should be addressed by designing the floor in accordance with BS EN 1995-1-1 and its UK National Annex. Or design to deflection limits, based on total dead and imposed loads for combined bending and shear of 0.003 x the span, with a maximum deflection of 14mm where strutting is provided, or 12mm where strutting is not provided.

In the experience of Hush Acoustics, based on the enquiries we receive, one of the main reasons why the level of deflection in metal web joists is greater than expected is because the joist centres are too far apart. Yes, it is perfectly plausible to use posi-joists at 600mm centres, but it can push the structural strength to its limits where other factors are outside the architect’s control.

Therefore, when designing a building with metal web floor joists it is far safer to build to joist centres of 400mm to prevent the risk of excessive deflection.

Treatments for creaking in existing floors

Unfortunately for many homeowners and developers, designing-out creakiness by reducing the joist centres is not an option. Often the issue only becomes apparent once the property is occupied and in-use.

The good news is that there are a wide range of fully tested retrofit solutions from Hush Acoustics that comply with the requirements set out by the NHBC, Robust Details and the Building Regulations in all UK nations. In many situations, this can dramatically improve if not eradicate a creaky floor problem, depending on its severity and associated design challenges.

Hush Acoustics’ products and systems are also recommended for new build. Designing a floor with reduced centres and all the other recommended structural elements may still be a big let-down for the end user due to, for example, very minor installation or product quality inconsistencies.

The best approach

So, the best approach is to design for enhanced acoustic performance by default, ignoring the outdated minimum standards which are not fit for purpose in today’s built environment.

One approach for existing properties is to fit timber shims under the floorboards and apply joist strips. Timber shims are thin wedges of wood that can be secured to the joists to make them level. After this levelling, Hush-10 Joist Strips can be applied to the tops of the joists.

Made from a unique felt which provides a resilient layer, Hush-10 Joist Strips resolve any remaining unevenness in the joists as well as providing additional isolation to deliver an acoustically dampened floor. Once the joist strips are in place, the existing flooring can then be re-fitted or alternatively Hush-Panel 28 acoustic floor panels can be used to create a floating floor over the strips for additional performance benefit. Where this is used, the perimeter will also need to be isolated using Hush Seal 20.

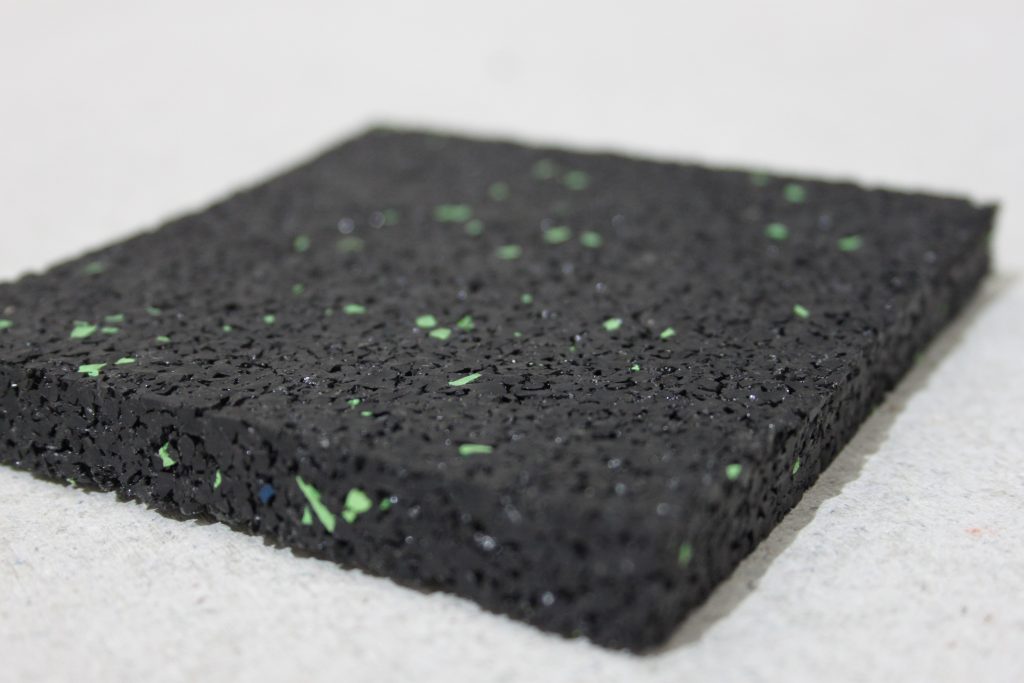

Another approach is to lay Hush Mat 15 over the existing floor once the boards have been screwed down tightly. This is a uniquely engineered acoustic rubber matting that contains high levels of mass making is ideal for achieving excellent impact sound reducing performance, as well as cutting airborne sound transmission. In fact, Hush Mat 15 also acts as an acoustic underlay which means there is no requirement for additional carpet underlay.

Find out more

If you are experiencing an issue with creaking floors or seeking acoustic guidance on the design of a structural floor which uses metal web joists, please contact Hush Acoustics.

As a UK manufacturer of acoustically insulting products and systems for buildings of all kinds for over 30 years, we have a wealth of technical know-how and resources to guide you to the right solution.

Find out more at www.hushacoustics.co.uk or call 0151 268 0488.

Hush Acoustics Ltd

Unit 2, Tinsley Industrial Estate

Shepcote Way

Sheffield

South Yorkshire

S9 1TH

Tel: 0114 551 8685

Fax: 0151 944 1146

Visit Supplier's page

Latest news

17th April 2025

Nuaire shares expertise at Specifi Mechanical Services events in 2025

Indoor air quality and ventilation manufacturing specialist Nuaire is pleased to be exhibiting at the Specifi Mechanical Services events once again in 2025.

Posted in Air Conditioning, Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Exhibitions and Conferences, Facility Management & Building Services, Heating, Ventilation and Air Conditioning - HVAC, Restoration & Refurbishment, Retrofit & Renovation

15th April 2025

West Fraser: CaberDek earns top marks from Home Counties carpentry specialist

A specialist carpentry sub-contractor covering housing sites across a large swathe of the Home Counties has come to value CaberDek from the West Fraser range for a variety of reasons: not least because the high quality panel product doesn’t destroy his operatives’ electric saws!

Posted in Articles, Building Industry News, Building Products & Structures, Building Systems, Case Studies, Restoration & Refurbishment, Retrofit & Renovation, Roofs, Timber Buildings and Timber Products, Wooden products

15th April 2025

GEZE: The Role of Access Control Systems in Enhancing Building Safety

Jane Elvins, Specification and Business Development Manager at GEZE UK, delves into the role of access control systems in enhancing building safety…

Posted in Access Control & Door Entry Systems, Architectural Ironmongery, Articles, Building Industry News, Building Products & Structures, Building Services, Doors, Facility Management & Building Services, Health & Safety, Restoration & Refurbishment, Retrofit & Renovation, Security and Fire Protection

11th April 2025

Don’t Do a Dave! It’s Time to Lock FIT Show 2025 in Your Calendar!

It’s that time again – FIT Show is back! You could be forgiven for thinking there won’t be much new to see when FIT Show returns to the NEC from 29 April – 1 May. Wrong!

Posted in Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Continuing Professional Development (CPD's), Exhibitions and Conferences, Information Technology, Innovations & New Products, Restoration & Refurbishment, Retrofit & Renovation, Seminars, Training

Sign up:

Sign up: