Hush: What is the best insulation for sound and fire?

One of the most common questions that arises in the design and specification process for acoustic floors or walls is how it will perform in the event of a fire. Hush Acoustics has more…

The materials we combine to create acoustic floors, ceilings and walls will usually have to meet other goals beyond sound reduction. This could be to minimise wall or floor depth or protect decorative features, but more fundamentally the floor or wall will also often need to offer fire resistance and provide a high level of thermal insulation.

Achieving a design that meets all these performance and design goals does, therefore, require careful consideration of materials.

Whenever there is an update to the minimum standards set out in any of the Building Regulations, there is the potential for well-intentioned aims in one area to impact adversely in others. We have seen this many times over the years in relation to acoustic products, and the good news is that product innovation has always provided a solution where one did not exist.

This is not always necessary, however, because sometimes there is a product that is already available and proven in the market to achieve the new standard expectations. The solution needed for a new standard may, therefore, be staring us in the face.

Building Safety Act

The broader focus on building safety which has emerged from the Building Safety Act means fire protection will undoubtedly be at the forefront of specification and design decisions going forward. That’s not to say fire safety was not central to specifications in previous generations, but it does mean higher standards will need to be adopted and not only for high rise buildings (HRBs).

The materials used to reduce sound transmission through separating walls and floors in connected homes, such as terraced houses and apartments, add density to the structure. But the types of materials normally used to disrupt or block soundwaves are often not fire resistant, resulting in a conflict of Building Regulations.

Under the Building Regulations covering England and Wales, for example, Approved Document B may stipulate a minimum performance level in respect of fire resistance for the separating wall or floor/ceiling construction, whereas Approved Document E will set-out the minimum levels of acoustic insulation to achieve compliance.

So how do we overcome this?

Engaging with acoustic product manufacturers like Hush at the early stages of the wall or floor design will help reduce the risk of non-compliance and potentially save time in the design process by making it possible to get the specification right first time. Advice on how to achieve the right combination of products and guidance on installation can pay huge dividends.

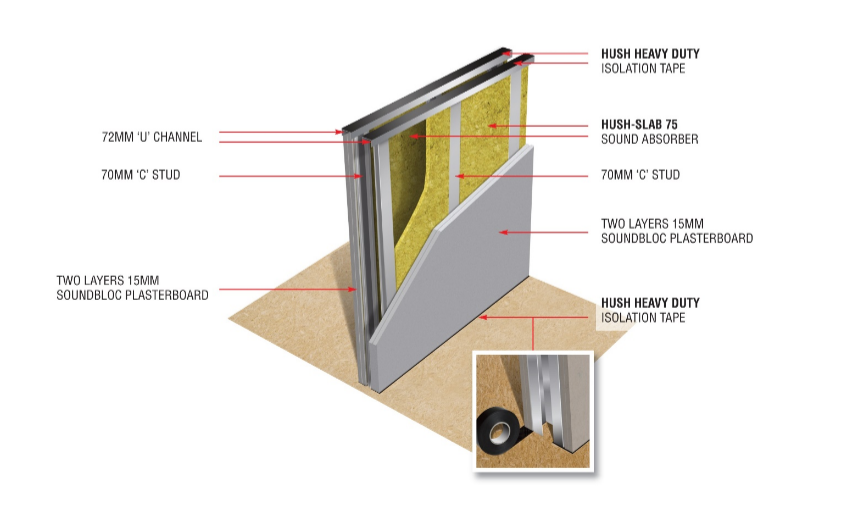

One product that is long established in the market yet perfect for meeting today’s acoustic performance requirements, while at the same time being a highly effective thermal insulator and offering A1 classification fire resistance is Hush Slab. This is a mineral wool sound absorber slab that is a key part of many of the fully tested acoustic wall, floor and ceiling systems developed by Hush.

Its fibre composition, which is derived from inorganic rock, is ideal for adding mass to wall and floor/ceiling constructions where there is a void as it will cut sound transmission extremely effectively. But it has excellent thermal resistance properties too, ranging from 2.85m2K/W for the thickest slab option, 100mm, to 0.70 in the thinnest 25mm product.

Products like Hush Slab have an important part to play in the future of safe, low carbon and sustainable buildings given their multi-functionality and durability credentials. Being able to ‘fit and forget’ a single product that ticks multiple boxes can make an important contribution to a smarter, more efficient build process, especially where fire safety is concerned.

For specialist acoustic advice and product data on Hush Slab and the other products and systems in the Hush Acoustics range visit www.hushacoustics.co.uk.

Hush Acoustics Ltd

Unit 2, Tinsley Industrial Estate

Shepcote Way

Sheffield

South Yorkshire

S9 1TH

Tel: 0114 551 8685

Fax: 0151 944 1146

Visit Supplier's page

Latest news

25th March 2025

Reduce sound transference with West Fraser CaberAcoustic

CaberAcoustic from West Fraser is a highly versatile, effective and economical sound-reducing flooring solution. Reducing both impact and airborne transmitted sounds, it can be laid over concrete and timber floors in both new and existing buildings.

Posted in Acoustics, Noise & Vibration Control, Articles, Building Industry News, Building Products & Structures, Building Services, Building Systems, Facility Management & Building Services, Floors, Interior Design & Construction, Interiors, Posts, Restoration & Refurbishment, Retrofit & Renovation, Timber Buildings and Timber Products

25th March 2025

Vent-Axia Kicks Off Charity Football Tournament in Support of Cancer Research UK

Ventilation leader Vent-Axia brought together leading building design professionals for an action-packed Charity Powerleague 5-a-side Football Tournament on Thursday 20th March in Shoreditch, London, in aid of Cancer Research UK.

Posted in Air Conditioning, Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Charity work, Facility Management & Building Services, Heating, Ventilation and Air Conditioning - HVAC

25th March 2025

Jane Elvins bolsters GEZE UK Specification team

GEZE UK, a leading manufacturer and provider of door, window and access control systems, is delighted to welcome Jane Elvins, who joins as Specification and Business Development Manager.

Posted in Access Control & Door Entry Systems, Architectural Ironmongery, Articles, Building Industry News, Building Products & Structures, Building Services, Doors, Facility Management & Building Services, Recruitment, Retrofit & Renovation, Security and Fire Protection, Windows

24th March 2025

Putting Glidevale Protect in the frame at InverTay Homes development

Leading building products manufacturer Glidevale Protect is supplying its construction and roofing membranes for a new timber frame housing development currently being constructed by InverTay Homes in Dundee.

Posted in Articles, Building Industry News, Building Products & Structures, Building Services, Building Systems, Case Studies, Facility Management & Building Services, Membranes, Restoration & Refurbishment, Retrofit & Renovation, Roofs, Sustainability & Energy Efficiency, Timber Buildings and Timber Products, Walls

Sign up:

Sign up: