Hush: Which resilient bars are best for acoustic insulation projects?

One of the most important ways to ensure sound transmission is minimised through a wall, floor or ceiling is to decouple the structural elements, such as joists, studwork or masonry, from those that face onto the room. Hush Acoustics has more…

When a new wall, floor or ceiling is created, plasterboard is typically used to create a lining. Very effective sound transmission paths will be created if the boards are directly fixed to the structure, either mechanically or through bonding, so it is crucial to find a way to isolate these elements from the structure.

Lightweight resilient bars, which are also referred to as sound breaker bars, are often used to provide the separation required in line with the ‘room within a room’ concept. But in order to determine which type of resilient bar is right for an acoustic design, it is important to understand their purpose, how to install them correctly and key design considerations when incorporating them.

In particular, the type of resilient bar chosen for a wall or ceiling lining will influence the acoustic improvement possible, speed of installation, overall thickness and loss of floor space or ceiling height within the room, and fire performance.

Standard resilient bars or clip systems?

Resilient bars are vibration absorbing corrugated steel bars which are mounted onto the structural wall or ceiling to allow the plasterboards or wall boards to ‘float’. Hush Acoustics offers two standard types of resilient bars – Hush Bar and Hush Bar Deep – which are designed to be mechanically fixed into position onto the masonry, studs or joists, and plasterboards are then attached to the bars using appropriate fixings.

By using resilient bars, the boards are isolated from the structure, helping to break the most significant paths for sound to travel from sources in the room, such as from speech, a TV or music, through the plasterboard and into the wall, floor or ceiling structure.

The bars act as springs, dissipating vibration and sound and improving the wall or floor/ceiling’s insulation against both impact and airborne sound. They are so effective that it is estimated resilient bars contribute up to one third of the airborne sound insulation performance, and almost all of the insulation against impact sound, in wall and ceiling systems constructed using mineral wool and acoustic plasterboard.

Both Hush Bar and Hush Bar Deep resilient bars are designed to be screw fixed to the underside of timber joists or battens at 600mm centres, and at 450mm centres on timber and metal stud walls. With Hush Bar, the void created has an overall depth of 16mm and they will suspend loads of up to 30kg/m2.

Create a deeper void

Whilst Hush Bar is suitable for many standard acoustic wall and floor/ceiling designs, in some applications it may be necessary to create a deeper void and use heavier plasterboards to achieve enhanced acoustic performance. In such cases, Hush Bar Deep would be recommended, as it creates a 30mm void – nearly double that of Hush Bar – and these resilient bars can support greater weights of up to 50kg/m2.

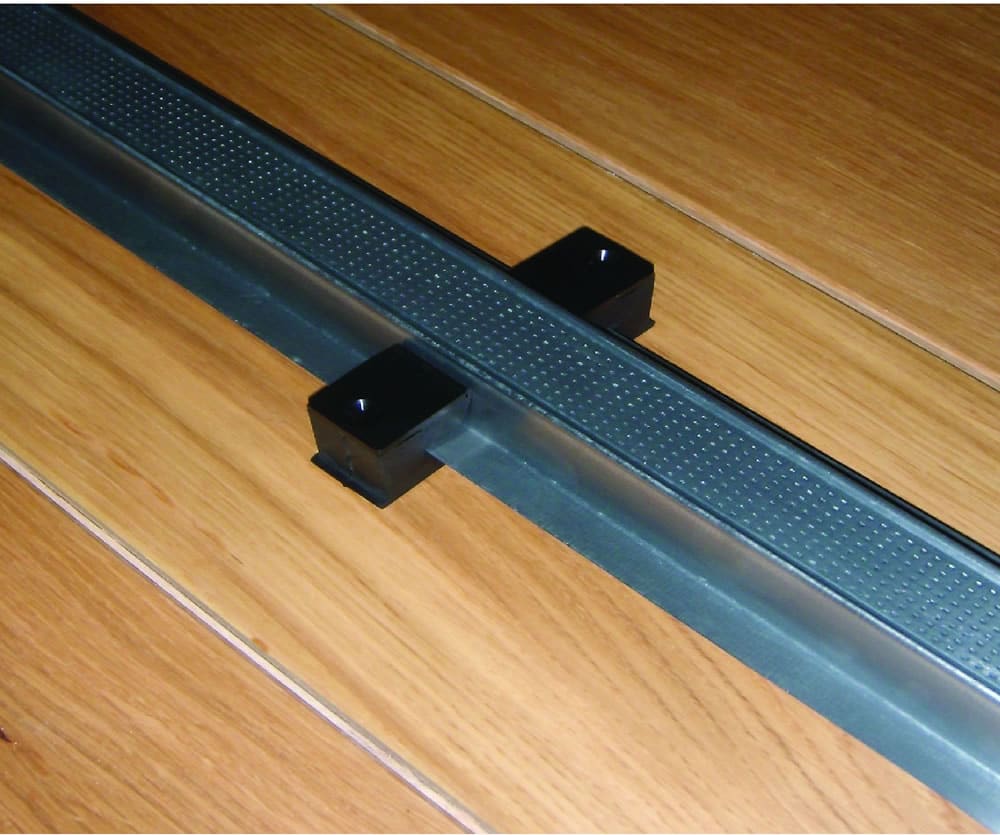

In addition to standard resilient bars, a number of clip on resilient bar systems are also available including two from Hush Acoustics – the Hush Bar Plus and Hush Bar Enhanced Resilient Clip and Bar System. These systems have been designed to be flexible, simple and easy to install, taking the form of a two-part system, unlike some of the more complex multi-part systems often used where acoustic isolation/decoupling is required.

Strong, flexible & lightweight

The Hush Bar Enhanced Resilient Clip and Bar System features clips made of a strong, flexible and lightweight material, and they are available in a variety of sizes to accommodate different thicknesses of ceiling drywall or other surfaces where soundproofing is desired. The clips are easily installed by drilling holes for the screws and then attaching them into place with screws or nails.

The Hush Bar Enhanced Resilient Clip and Bar System is the system with the highest high load bearing capacity because the clips are fixed from both sides – up to 80kg/m2. And it is offers the highest acoustic performance too.

With most standard resilient bars, an acoustic improvement of 17 dB can be expected compared to standard dry lining approaches, but the Hush Bar Enhanced Resilient Clip and Bar System can improve performance by as much as 23 dB.

Hush Bar Plus is similar in concept but uses metal clips rather than plastic, providing decoupling via a spring clip, a metal bar, connecting sleeves and a perimeter channel. It is suitable for heavier plasterboards too, matching Hush Bar Deep’s ability to suspend up to 50kg/m2.

Can resilient bars be used as part of a fire resistant acoustic design?

The level of fire resistance provided by an acoustic wall or ceiling lining is a key consideration in many projects, so it is important to select a resilient bar that is supported by fire test data. One such product is the Hush Bar Deep, which has been tested to offer a 60 minute fire-rating as part of an acoustic floor design featuring a 200mm timber joist, with Hush Slab 100 fitted between the joists and two layers of 15mm Siniat dB Board.

It is, however, best practice to ensure the fire performance sought in a proposed acoustic system design is verified by a suitably qualified fire engineer or consultant.

Specialist technical guidance and support

Hush Acoustics’ technical team can advise on the most appropriate resilient bar system for any acoustic project, taking into account all the performance characteristics and installation time. Its resilient bars feature in many of its fully tested acoustic systems which are compliant with all the UK’s Building Regulations relating to the passage of sound within buildings, including Approved Document E, as well as bespoke acoustic designs to suit all kinds of new build and conversion projects.

Find out more at www.hushacoustics.co.uk.

Hush Acoustics Ltd

Unit 2, Tinsley Industrial Estate

Shepcote Way

Sheffield

South Yorkshire

S9 1TH

Tel: 0114 551 8685

Fax: 0151 944 1146

Visit Supplier's page

Latest news

29th April 2025

Senior pledges to ‘bee’ part of the solution with new biodiversity initiative

Senior Architectural Systems has installed its first on-site beehive, marking another step forward in its commitment to sustainability and biodiversity.

Posted in Articles, Building Industry News, Building Products & Structures, Building Services, Curtain Walling, Doors, Glass, Glazing, Innovations & New Products, news, Restoration & Refurbishment, Retrofit & Renovation, Sustainability & Energy Efficiency, Walls, Windows

29th April 2025

West Fraser range delivering key benefits for South-East carpentry company

An experienced carpenter and building site manager who has recently set up his own company is using high performance panel products from the West Fraser range.

Posted in Articles, Building Industry News, Building Products & Structures, Building Systems, Case Studies, Garden, Restoration & Refurbishment, Retrofit & Renovation, Sustainability & Energy Efficiency, Timber Buildings and Timber Products

29th April 2025

CPD Courses Available Online From Ecological Building Systems

Ecological Building Systems, a leading supplier of natural building products for sustainable construction, has revealed its comprehensive CPD programme for the year ahead.

Posted in Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Continuing Professional Development (CPD's), Information Technology, Innovations & New Products, Insulation, Restoration & Refurbishment, Retrofit & Renovation, Seminars, Sustainability & Energy Efficiency, Training, Walls, Waste Management & Recycling

29th April 2025

WindowBASE launches new prospect databases at FIT Show

Visit WindowBASE at the FIT Show to see first-hand how it helps companies find new customers – the company is launching an easy-to-use, intuitive platform on Stand G16 at the NEC Birmingham from 29th April – 1st May.

Posted in Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Doors, Exhibitions and Conferences, Glass, Glazing, Information Technology, Innovations & New Products, Posts, Publications, Research & Materials Testing, Restoration & Refurbishment, Retrofit & Renovation, Windows

Sign up:

Sign up: