Hydro International unveils the next-generation modular Downstream Defender® Select

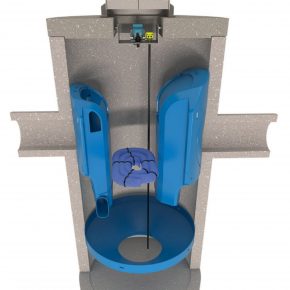

Hydro International is launching the new Downstream Defender® Select, a modular next-generation hydrodynamic separator optimised for the treatment of surface water runoff.

Combining the industry-leading performance of the Downstream Defender® with a wide range of customisation options, the Downstream Defender® Select now enables engineers to tailor their drainage designs to meet specific pollutant removal objectives, such as the Simple Index Approach (SIA).

The modular nature of the system means that designers are able to select from a spectrum of configuration options to deliver site-specific treatment objectives, from simple betterment to advanced vortex separation with oil and floatables removal and retention enhancements.

Like its predecessor, the Downstream Defender® Select provides exceptional treatment performance, reliably capturing and retaining sediments, oils and hydrocarbons, litter and floatables from surface water runoff from roads, car parks or any impermeable area.

The patented internal components ensure a streamlined flow path through the unit, enhancing its separation capabilities, and pollutants are retained in designated zones within the chamber, with options for enhanced retention of sediments and oils and hydrocarbons

Design and installation is now made easier and more cost-effective, as the Downstream Defender® Select benefits from an extended range of chamber sizes, multiple connecting pipe sizes, and up to three inlets. This removes any need to factor in costly, complicated pipe connections, couplings or additional chambers.

For quick and straightforward installation, the Downstream Defender® Select is delivered pre-installed inside a concrete chamber so that, once positioned, it can be directly connected to pipework.

For sites where access to heavy lifting equipment is difficult, the Downstream Defender® Select can also be supplied in a lightweight, easy-handling plastic chamber.

In addition, Hydro-Logic® Smart Maintenance technology can now be integrated into the system. This remote monitoring capability provides real-world insight into sediment and/or water levels, sending automated alerts to notify users of when the Downstream Defender® Select needs emptying or if a blockage occurs downstream.

Data captured by the ATEX/IECEx-rated loggers and sensors also enable owners to forecast future maintenance requirements and develop cost-effective maintenance plans.

Building upon the foundational Downstream Defender® technology that is already protecting waterways across the UK, the Downstream Defender® Select has been tested in accordance with the British Water Code of Practice Assessment of Manufactured Treatment Devices Designed to Treat Surface Water Runoff, meaning that engineers can have full confidence in its performance, effectiveness and reliability.

To add further confidence and reduce risk, engineers can design the Downstream Defender® Select quickly and easily using Hydro International’s dedicated online design tool. A simple two-step process enables users to size and then refine their design for optimum performance with optional Smart Maintenance.

The tool provides the option to create and save multiple designs, and its one-click data output feature makes project work simple and straightforward. Visit hydro-int.design to create an account and start designing.

Ben Puddy, Regional Technical Manager for Hydro International, says: “The Downstream Defender® Select is the most customisable product we have ever developed. It meets and exceeds all standards of the previous model and provides designers with almost limitless configurations to choose from, including performance levels, multiple inlets, pipe sizes, chamber sizes, chamber types and monitoring options. This allows designers to fine-tune and optimise their design to meet the specific needs of the site.”

To find out more about how the Downstream Defender® Select can help you to meet surface water quality objectives and to watch the video, please see here.

Latest news

28th March 2025

Ideal Heating Commercial announces 10-year warranty on Evomax 2 boiler

Evomax 2, the UK’s number one selling commercial wall-mounted boiler from Ideal Heating Commercial, is now available with a 10-year warranty.

Posted in Articles, Building Industry News, Building Products & Structures, Building Regulations & Accreditations, Building Services, Facility Management & Building Services, Heating Systems, Controls and Management, Heating, Ventilation and Air Conditioning - HVAC, Innovations & New Products, Pipes, Pipes & Fittings, Plumbing, Retrofit & Renovation, Sustainability & Energy Efficiency, Videos

28th March 2025

FLIR Si1-LD Acoustic Imaging Camera for Compressed Air Leak Detection

FLIR, a Teledyne Technologies company, introduces the Si1-LD, an industrial acoustic imaging camera that brings faster and more accurate compressed air leak detection to those operating on a modest condition monitoring budget.

Posted in Acoustics, Noise & Vibration Control, Articles, Building Industry News, Building Products & Structures, Building Services, Facility Management & Building Services, Information Technology, Innovations & New Products, Retrofit & Renovation, Sustainability & Energy Efficiency, Thermal Imaging and Monitors

28th March 2025

LIFTEX 2025 Seminar programme announced

Registration has opened for LIFTEX 2025. Now in its 37th year, LIFTEX 2025 is the UK’s only dedicated exhibition for the lift, escalator and access industry and takes place only once every three years.

Posted in Access Control & Door Entry Systems, Accessibility, Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Regulations & Accreditations, Building Services, Exhibitions and Conferences, Facility Management & Building Services, Health & Safety, Retrofit & Renovation, Security and Fire Protection, Seminars

28th March 2025

MCRMA welcomes ArcelorMittal UK to membership

A UK division of the global steelmaking business ArcelorMittal has become the latest new member of the MCRMA, the industry association representing the metal building envelope sector.

Posted in Articles, Building Associations & Institutes, Building Industry News, Building Products & Structures, Building Systems, Cladding, Facades, Posts, Restoration & Refurbishment, Retrofit & Renovation, Roofs, Steel and Structural Frames, Walls

Sign up:

Sign up: