Kemper System showcased at Museum of Liverpool

Kemper System has played a part in refurbishing of a section of the Museum of Liverpool, which spans an area 110 metres long by 60 metres wide and is 26 metres high at its tallest point.

The waterfront museum is one of the largest in the country and is positioned over the Leeds Liverpool canal link.

Architects Bickerdike Allen Partners (BAP) was responsible for the remedial works, which saw the removal of the original terrace steps and the failed single ply waterproofing of two separate terraces to the north and south of the building.

Kemper System’s solvent-free Kemperol 2K-PUR liquid waterproofing system was used for the new terrace support structure and structural deck, and installed by roofing contractors K Pendlebury & Sons.

The work was undertaken in two phases; firstly, the original steps and terraces structure were removed by main contractor WH Snow – this was followed by Kemperol 2K-PUR being used to waterproof the original concrete slab underneath.

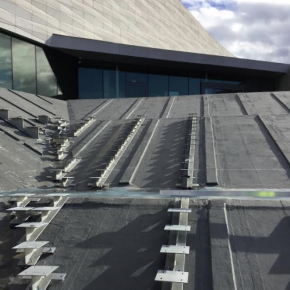

The next phase saw a complex steel support system installed and bolted through the new waterproofed concrete slab.

Further waterproofing took place, with very specific detailing needed – this included 672 metres of galvanised steel stepped beams with in excess of 200 small individual supports and over 3,600 individual bolt heads securing the steel to the slab.

Further work included the application of a protective coating consisting of Kempertec EP5 Primer and quartz sand to flat terrace areas where cement bonded blockwork supports were being used.

The museum was kept open to the public throughout the project, including all structural work, waterproofing and installation of the new replacement terrace steps.

Neilan Symondson, of K Pendlebury, commented: “This was an extremely intricate job which had to be carried out in challenging weather conditions as the building is located right on the waterfront.

“The Kemperol 2K-PUR was applied on slopes ranging from 20 to 35 degrees with very complex and specific detailing. It had to provide a guaranteed watertight solution, resolving many issues resulting from the original construction and retention of external cladding finishes.

“Kemperol 2K-PUR was an ideal solution as it’s applied wet-on-wet, which made it much easier for us to work around the extensive structural detailing and awkward shapes, ensuring they were waterproofed effectively.

“As it’s odourless, this also assured the client that anyone visiting or working at the museum during the works wouldn’t be affected by any disruptive odours.”

Upon completion, there was seating, terraces and steps at both ends of the Museum, leading to two viewing platforms providing observation points over iconic parts of the city, including the River Mersey and Liverpool Bay.

Kemper System’s Stuart Hicks added: “This was a complex, high-profile project that had to meet a number of strict requirements with no room for error.

“Crucially, the application process for Kemperol 2K-PUR will ensure the waterproofing performs to the highest standards to keep the museum watertight for many years to come.”

Contact

Stuart Hicks

Email: enquiries@kempersystem.co.uk

KEMPER SYSTEM LTD

Kemper House, 30 Kingsland Grange

Woolston

Warrington

Cheshire

WA1 4RW

Tel: 01925 445532

Visit Supplier's page

Latest news

11th April 2025

Don’t Do a Dave! It’s Time to Lock FIT Show 2025 in Your Calendar!

It’s that time again – FIT Show is back! You could be forgiven for thinking there won’t be much new to see when FIT Show returns to the NEC from 29 April – 1 May. Wrong!

Posted in Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Continuing Professional Development (CPD's), Exhibitions and Conferences, Information Technology, Innovations & New Products, Restoration & Refurbishment, Retrofit & Renovation, Seminars, Training

11th April 2025

Insight Data: Boost construction success with project and prospect data

For those working in construction – in whatever capacity – the last few years haven’t been much fun. And according to the latest statistics, it would seem the challenges are continuing – Alex Tremlett, Insight Data’s Commercial Director, has more…

Posted in Articles, Building Industry News, Building Services, Information Technology, news, Research & Materials Testing

11th April 2025

ASSA ABLOY EMEIA: Learn how to tackle the security challenges of digitalising access with insights from industry experts

In a new series of videos, experts in various specialisms within ASSA ABLOY share their expertise on digital access, including the complexities to overcome and the range of benefits for those who get digital access right…

Posted in Access Control & Door Entry Systems, Architectural Ironmongery, Articles, Building Industry News, Building Products & Structures, Building Services, Doors, Facility Management & Building Services, Information Technology, Innovations & New Products, Posts, Restoration & Refurbishment, Retrofit & Renovation, Security and Fire Protection, Videos

10th April 2025

Geberit completes 150 Acts of Kindness

Geberit has raised nearly £14,000 for various charities through its ‘150 Acts of Kindness’ initiative, a year-long programme of fundraising and volunteering to mark the company’s 150th anniversary in 2024.

Posted in Articles, Bathrooms & Toilets, Bathrooms, Bedrooms & Washrooms, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Charity work, Drainage, Interiors, Pipes, Pipes & Fittings, Plumbing, Restoration & Refurbishment, Retrofit & Renovation

Sign up:

Sign up: