LIEBIG: How a uniquely designed modular anchor offers cost savings without compromise

An innovative approach to concrete anchoring offers assured performance without a cost premium, whilst at the same time increasing application versatility, thanks to a unique mechanical anchor design by LIEBIG.

The LIEBIG Superplus BLS, which is available from EJOT UK, is unlike any other heavy duty concrete anchor, being the only self-undercutting anchor that, without special tools, creates its own undercut. It works differently to all other types of concrete attachment products to deliver game-changing results.

What does this mean for project engineers, designers, specifiers and contractors?

In short, Superplus BLS will provide more ‘kN per £’, with the assurance of ETA and UKTA certified performance but without the price tag usually associated. It is capable of offering significantly improved tensile performance – 200% that of other heavy duty type anchors, 300% of the performance possible with throughbolts and 250% that of the largest concrete screws.

Being designed with several core components or modules that can be sized and assembled to meet the specific needs of an application, an immediate cost efficiency benefit is realised, because of EJOT’s ability to manufacture non-standard sizes in short lead times at a fraction of what it would cost for bespoke sized anchors.

But it is not just about cost savings for bespoke anchors. Superplus BLS has numerous other advantages, particularly in terms of its performance capabilities – shear and tensile strength – which stem from its unique mechanical inter-locking design.

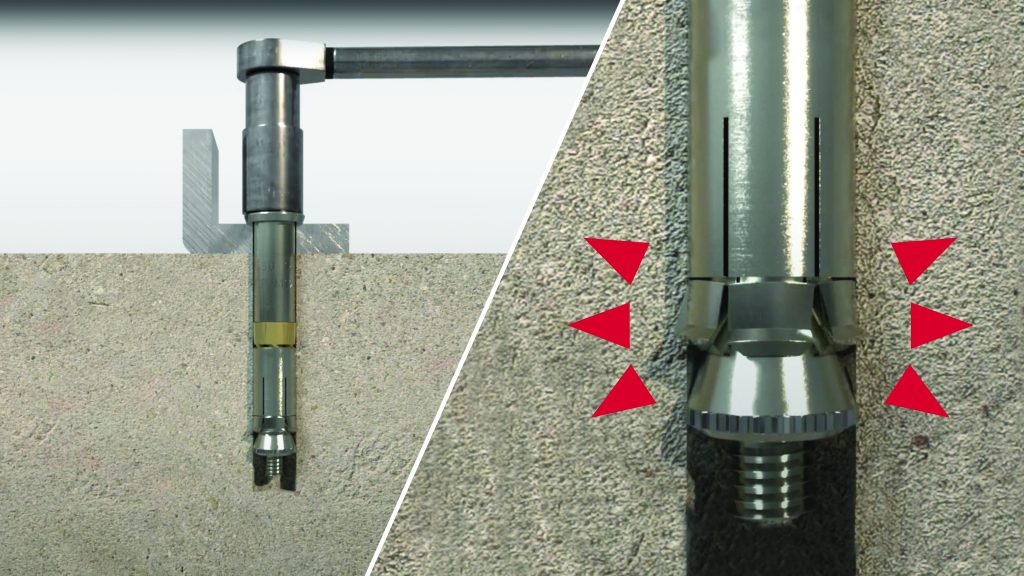

Simplicity is key to its success. By applying the required torque, a cone is drawn upwards, which drives six chamfered teeth outwards to deform and compress the concrete. This all occurs in a single mechanical process with the teeth creating the undercut without the need for special tools. Only a simple hole needs to be drilled to the correct diameter and depth, and with the correct torque applied.

As a result, Superplus BLS is not reliant on friction to achieve the hold – this is the case with other mechanical expansion anchors, giving it its superior resistance in shear and tension.

Twice the standard performance

A Superplus BLS anchor would return twice the performance resistance or recommended load values of a standard heavy duty expansion anchor in an application where the diameter and embedment depth are the same.

And whilst there are concrete anchors available that can return even greater performance, the compromise is not only significant additional cost and lengthy lead times, but also the need for a greater embedment depth. This may not be possible in every application in any case and will also dictate the spacing of the anchors, which could ultimately lead engineers and designers to provide an anchoring application that expensive and over specified.

What underpins the Superplus BLS anchor’s versatility is its ability to provide high performance through self-undercutting without deep embedment and at closer spacings. It represents a lower risk option for engineers and designers because of its innovative design, which makes it particularly suitable for safety critical applications including in nuclear power plants, as well as in the general industrial, petrochemical and pharmaceutical industries.

From pipework and mechanical support to switchgear and instrumentation units, Superplus BLS has been used in multiple applications where the design seeks to eliminate risk. Independent verification is demonstrated through the product’s long-held ETA (European Technical Assessment) and early UKTA accreditation, plus ICC nuclear approvals.

It all adds up to an anchoring solution which demonstrates the level of expertise within EJOT’s LIEBIG division and how the innovative products it is bringing to the market offer engineers, architects and specifiers benefits across the board. From strength and cost to flexibility of design, what the Superplus BLS can offer in a single package is as yet unmatched in the concrete anchoring market.

Find out more at www.ejot.co.uk/LIEBIG_BLS

Email: [email protected]

Visit Supplier's page

Latest news

25th March 2025

Reduce sound transference with West Fraser CaberAcoustic

CaberAcoustic from West Fraser is a highly versatile, effective and economical sound-reducing flooring solution. Reducing both impact and airborne transmitted sounds, it can be laid over concrete and timber floors in both new and existing buildings.

Posted in Acoustics, Noise & Vibration Control, Articles, Building Industry News, Building Products & Structures, Building Services, Building Systems, Facility Management & Building Services, Floors, Interior Design & Construction, Interiors, Posts, Restoration & Refurbishment, Retrofit & Renovation, Timber Buildings and Timber Products

25th March 2025

Vent-Axia Kicks Off Charity Football Tournament in Support of Cancer Research UK

Ventilation leader Vent-Axia brought together leading building design professionals for an action-packed Charity Powerleague 5-a-side Football Tournament on Thursday 20th March in Shoreditch, London, in aid of Cancer Research UK.

Posted in Air Conditioning, Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Charity work, Facility Management & Building Services, Heating, Ventilation and Air Conditioning - HVAC

25th March 2025

Jane Elvins bolsters GEZE UK Specification team

GEZE UK, a leading manufacturer and provider of door, window and access control systems, is delighted to welcome Jane Elvins, who joins as Specification and Business Development Manager.

Posted in Access Control & Door Entry Systems, Architectural Ironmongery, Articles, Building Industry News, Building Products & Structures, Building Services, Doors, Facility Management & Building Services, Recruitment, Retrofit & Renovation, Security and Fire Protection, Windows

24th March 2025

Putting Glidevale Protect in the frame at InverTay Homes development

Leading building products manufacturer Glidevale Protect is supplying its construction and roofing membranes for a new timber frame housing development currently being constructed by InverTay Homes in Dundee.

Posted in Articles, Building Industry News, Building Products & Structures, Building Services, Building Systems, Case Studies, Facility Management & Building Services, Membranes, Restoration & Refurbishment, Retrofit & Renovation, Roofs, Sustainability & Energy Efficiency, Timber Buildings and Timber Products, Walls

Sign up:

Sign up: