New machine adds significant capacity to Hadley Group’s capabilities in the steel framing market

Following the acquisition of Hadley Steel Framing (HSF) in 2018, Hadley Group has further strengthened its position and improved its capabilities in the steel framing market by investing in a new purpose-built machine at its Oldbury production site.

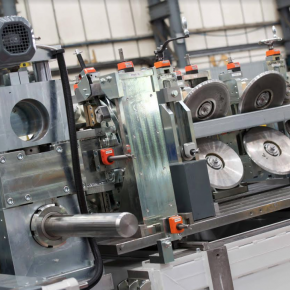

The Purposed Built Steel Framing Machine joins Hadley Group’s extensive portfolio of world-class equipment and will allow the company to offer greater speed and flexibility in producing steel framing products.

The Purposed Built Steel Framing Machine joins Hadley Group’s extensive portfolio of world-class equipment and will allow the company to offer greater speed and flexibility in producing steel framing products.

The new machine takes steel coil and processes it through a linear system of equipment, adding features to the strip before it is cold rollformed into a series of shapes, such as U’s, C’s and Z sections, angles and odd legged channels (either pierced or plain), depending on individual customer requirements. The custom rollformed profiles are then supplied for the construction of steel frame structures and buildings.

The coil-fed system offers superior product quality control of hole positions and end flare, which enables the components to be functionally fitted together with greater speed. Investment in many connection features within the punch system allows it to support low, medium and high rise framed buildings. The machine can produce all types of metal-framed profiles from S250 to S550 structural steels and in lengths from 200mm to 12m, all with individual inkjet marks for product traceability.

Working closely with the supplier, the Hadley Purposed Built Steel Framing Machine came to fruition after a 10-month design and build process. The manufacturer collaborated with the Hadley Group to ensure that the machine would be able to optimise profiles and production processes to suit the company’s needs. The machine is now fully integrated into Hadley Group’s Building Products Division, based at Oldbury, and the benefits of the Hadley Purposed Built Steel Framing Machine are already proving worthwhile, increasing product quality, production output and adding the much-needed capacity in the marketplace. What’s more, the Hadley Purposed Built Steel Framing Machine reduces scrap by more than 25%.

James Bishop, Regional Director of Operations – International, at Hadley Group comments: “This is an exciting investment for Hadley Group, enabling us to strengthen our position in the Steel Framing market during such uncertain times. It streamlines the production of framing profiles, going from enquiry to production in a matter of hours and enabling profiles to be delivered to the customer efficiently. It will also strengthen the integration of the recent acquisition of HSF into Hadley Group and ensure that Hadley Group stays at the forefront of steel framed structures in the UK.”

Latest news

28th March 2025

Ideal Heating Commercial announces 10-year warranty on Evomax 2 boiler

Evomax 2, the UK’s number one selling commercial wall-mounted boiler from Ideal Heating Commercial, is now available with a 10-year warranty.

Posted in Articles, Building Industry News, Building Products & Structures, Building Regulations & Accreditations, Building Services, Facility Management & Building Services, Heating Systems, Controls and Management, Heating, Ventilation and Air Conditioning - HVAC, Innovations & New Products, Pipes, Pipes & Fittings, Plumbing, Retrofit & Renovation, Sustainability & Energy Efficiency, Videos

28th March 2025

FLIR Si1-LD Acoustic Imaging Camera for Compressed Air Leak Detection

FLIR, a Teledyne Technologies company, introduces the Si1-LD, an industrial acoustic imaging camera that brings faster and more accurate compressed air leak detection to those operating on a modest condition monitoring budget.

Posted in Acoustics, Noise & Vibration Control, Articles, Building Industry News, Building Products & Structures, Building Services, Facility Management & Building Services, Information Technology, Innovations & New Products, Retrofit & Renovation, Sustainability & Energy Efficiency, Thermal Imaging and Monitors

28th March 2025

LIFTEX 2025 Seminar programme announced

Registration has opened for LIFTEX 2025. Now in its 37th year, LIFTEX 2025 is the UK’s only dedicated exhibition for the lift, escalator and access industry and takes place only once every three years.

Posted in Access Control & Door Entry Systems, Accessibility, Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Regulations & Accreditations, Building Services, Exhibitions and Conferences, Facility Management & Building Services, Health & Safety, Retrofit & Renovation, Security and Fire Protection, Seminars

28th March 2025

MCRMA welcomes ArcelorMittal UK to membership

A UK division of the global steelmaking business ArcelorMittal has become the latest new member of the MCRMA, the industry association representing the metal building envelope sector.

Posted in Articles, Building Associations & Institutes, Building Industry News, Building Products & Structures, Building Systems, Cladding, Facades, Posts, Restoration & Refurbishment, Retrofit & Renovation, Roofs, Steel and Structural Frames, Walls

Sign up:

Sign up: