Raising the Roof and Standards: How Smartroof is addressing the Performance Gap

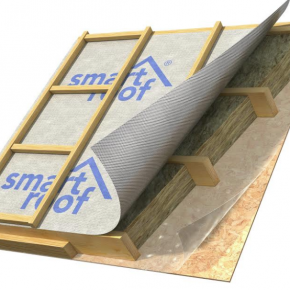

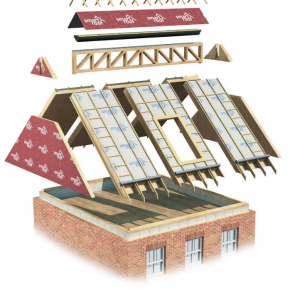

Smartroof’s offsite modular roof system attracts architects and builders alike. It is manufactured in a factory environment governed by strict quality procedures, which helps eliminate any risk of cold spots that may arise from trade methods onsite. This is an important factor in the drive to close the performance gap.

The Performance Gap

The performance gap is a term commonly used to denote the disparity that is found between the energy use predicted in the design stage of buildings and the energy use of those buildings in operation.

In recent years, the construction industry and government have grown increasingly concerned over the potential gap between design and as-built energy performance. It could undermine a building’s vital role in delivering the national carbon reduction plan and damage consumer confidence if energy bills are higher than anticipated.

Improving Energy Efficiency

There is a strong argument that focusing on the fabric of a building is the most cost effective, reliable and robust method of achieving compliance with future building regulations, as getting the fabric right will save energy throughout the whole life span of the house.

As designers focus on improving the fabric of the buildings by reducing wall, floor and roof U-values, the proportion of heat flow through thermal bridging becomes greater and Part L 2013 has much greater emphasis on thermal bridging as these heat losses were often over-looked in the past.

Statistics show that up to 35% of the heat loss in a well-insulated house is through thermal bridges. With 41 different potential thermal bridging junction types being identified within the SAP 2012, it’s important that designers address the thermal bridging details to minimise heat loss.

How Smartroof is addressing the Performance Gap

Smartroof offers consistent and predictable thermal performance that can be computer modelled in advance to accurately assess the thermal efficiency of individual buildings at the design stage.

The Smartroof system’s interlocking design makes it an ideal roof solution for those developers adopting a fabric first approach.

In traditional structures the junctions between elements of the building fabric often require special detailing so as not to compromise the overall SAP calculation, but Smartroof’s factory insulated panels eliminate voids or cold spots.

Production of the Smartroof system in a factory environment makes it easier to enforce strict quality standards more effectively than with multi-trade teams onsite.

The Smartroof solution offers significant increases in design flexibility as its insulation levels can be easily upgraded. This allows the client to ‘future proof’ their roof as U-values as low as 0.09 W/m2 K can easily be achieved.

Smartroof has revolutionised room in roof construction in the housing sector with it’s innovative panel system that can be installed in hours, not days.

Specifying Smartroof can also help your client overcome the following challenges:

• Health & Safety

• Skills Shortage

• Build Speed

• Quality of Product

• Cost Savings

Health and Safety Benefits

Smartroof is delighted to have won the ‘Best Health and Safety Product’ award at the 2018 Housebuilder Product Awards.

Traditional room-in-roof construction is vulnerable to major risks caused by numerous factors including the erection of scaffolding and manual handling whilst working in confined spaces and with falling brickwork.

In addition to these, there are risks involved in working at height on attic trusses or top-hats and purlins. This means that the roof can take weeks to erect, insulate and make watertight.

With Smartroof the number of hours working at height are dramatically reduced, while the risk of falling blockwork, use of power tools in confined spaces, and manual handling of steels is completely eliminated.

Like all Smartroof products, the Classic system arrives in a single load, reducing materials handling and vehicle movements onsite.

Sean Og Coyle, Smartroof MD, commented: “Site safety is a major priority for Smartroof, so we are thrilled to have won the award for Best Health and Safety product.

“We have worked hard to develop a product that overcomes the health and safety risks associated with traditional roof construction and addresses the issues our customers face.”

Addressing the Skills Shortage

The construction sector is in the grips of a skills shortage which is limiting construction activity and increasing labour costs at the same time.

The shortage has recently hit its worst recorded level and it is expected to worsen over the coming years and decades, with the recruitment of new talent failing to keep up with the rate of retirement.

The Chartered Institute of Building (CIOB) has reported that the industry will need to find 157,000 new recruits by 2021 in order to keep up with demand.

Smartroof is a factory fabricated room in roof system and can be installed in one day. This helps to free up the house builders skilled trade onsite to speed up the build programme.

Visit Supplier's page

Latest news

17th April 2025

Nuaire shares expertise at Specifi Mechanical Services events in 2025

Indoor air quality and ventilation manufacturing specialist Nuaire is pleased to be exhibiting at the Specifi Mechanical Services events once again in 2025.

Posted in Air Conditioning, Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Exhibitions and Conferences, Facility Management & Building Services, Heating, Ventilation and Air Conditioning - HVAC, Restoration & Refurbishment, Retrofit & Renovation

15th April 2025

West Fraser: CaberDek earns top marks from Home Counties carpentry specialist

A specialist carpentry sub-contractor covering housing sites across a large swathe of the Home Counties has come to value CaberDek from the West Fraser range for a variety of reasons: not least because the high quality panel product doesn’t destroy his operatives’ electric saws!

Posted in Articles, Building Industry News, Building Products & Structures, Building Systems, Case Studies, Restoration & Refurbishment, Retrofit & Renovation, Roofs, Timber Buildings and Timber Products, Wooden products

15th April 2025

GEZE: The Role of Access Control Systems in Enhancing Building Safety

Jane Elvins, Specification and Business Development Manager at GEZE UK, delves into the role of access control systems in enhancing building safety…

Posted in Access Control & Door Entry Systems, Architectural Ironmongery, Articles, Building Industry News, Building Products & Structures, Building Services, Doors, Facility Management & Building Services, Health & Safety, Restoration & Refurbishment, Retrofit & Renovation, Security and Fire Protection

11th April 2025

Don’t Do a Dave! It’s Time to Lock FIT Show 2025 in Your Calendar!

It’s that time again – FIT Show is back! You could be forgiven for thinking there won’t be much new to see when FIT Show returns to the NEC from 29 April – 1 May. Wrong!

Posted in Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Continuing Professional Development (CPD's), Exhibitions and Conferences, Information Technology, Innovations & New Products, Restoration & Refurbishment, Retrofit & Renovation, Seminars, Training

Sign up:

Sign up: