SikaBit® completes Sika’s flat roofing portfolio with Safe2Torch Bitumen range

Sika is to build on its UK market leading position as a manufacturer of liquid-applied and single ply roofing membranes with the launch of the SikaBit® range bituminous roofing systems.

These have been developed to answer the requirements of NFRC (National Federation of Roofing Contractors) Safe2Torch guidelines.

The move follows a record-breaking year of sales for the company’s roofing division in 2018, with year-on-year growth across roofing for the past three years.

With Sika’s acquisition of bituminous roofing system manufacturing capabilities in Europe, and advances in bituminous membrane technology, the company is now set to capitalise on trust in the Sika brand and service offering to leverage the opportunity in specification of bitumen roofs.

Rod Benson, head of Sika’s roofing business, commented: “Bituminous systems still account for at least half of flat roof refurbishments in the UK.

“Our focus has always been on bringing the most advanced roofing technologies to the marketplace, combined with the highest levels of service, technical support and safety best practice.

“As a technically-advanced bituminous system, SikaBit® allows us to continue that approach with proven technology that offers specifiers another option for accessing Sika’s renowned package of service, technical support and guarantees.”

“Thanks to the launch of the NFRC’s Safe2Torch guidelines in 2017, we have been able to develop our systems specifically to meet their criteria, ensuring the highest standards of Safe2Torch due diligence and accountable product performance.”

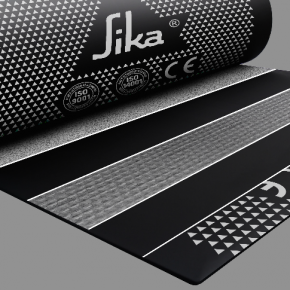

A fully BBA-approved range of torch-on and self-adhesive bituminous membranes, SikaBit® provides a total solution for a high-performance waterproof roof build-up, comprising an air & vapour control layer (AVCL), underlay and a hard-wearing cap sheet.

The SikaBit® Pro Bituminous Membrane range includes flame-free detailing options for completely Safe2Torch-compliant roof installations, along with a root-resistant offer for green roof applications and a solution for inverted roofs.

Rod added: “With SikaBit®, we’re not just launching a bituminous membrane – we are re-thinking bituminous membranes and offering a complete system that can be tailored to meet the design criteria and safety requirements of any new build or refurbishment flat roof.

“This proven, next generation bitumen technology will be offered with all the technical, application support and customer-service specifiers expect from Sika, including installation by a national network of fully-trained Certified Contractors and a suite of guarantee options to provide complete peace of mind.

“We have invested significantly in putting in place the infrastructure we need to enter the bitumen market, including recruitment and training of a dedicated SikaBit® sales and customer support team.”

Developed to combine the flexibility and tensile strength of an SBS membrane with the hardwearing properties and UV stability of APAO, SikaBit® Pro Bituminous Membranes leverage these advanced bitumen technologies to ensure both exceptional durability and ease and speed of application.

At launch, the SikaBit® range will include three core systems designed to meet the requirements of most roof environments. A Safe2Torch system will provide a roof build up that combines torch-on and self-adhesive components for both Safe2Torch zones and flame-free areas. The range will also include an inverted roof system and a green roof system.

All SikaBit® systems have been extensively tested and Sika has developed a wide-ranging training course for its Certified Contractors, including Safe2Torch guidance, which will be delivered at the company’s dedicated training centres with technical support also available on site.

The SikaBit® training course will include training in all aspects of the product range and has been developed in close partnership with the NFRC.

Gary Walpole, from the NFRC, commented: “We are delighted that Sika chose to involve us in putting together the training course for SikaBit® from the very earliest stages so that we could really embed the principles of Safe2Torch in the way the system is installed on site.

“It’s good to see an industry leader like Sika embracing Safe2Torch in both product development and training as we all work towards making sites safer for both contractors and end users.”

Rod Benson added: “There may be some who are surprised by our decision to launch a range of bituminous membranes but we believe the SikaBit® range joins the dots for specifiers by offering them a complete solution from a trusted supplier that they can rely on for product quality, technical support, safety best practice, customer service and robust guarantees.”

Latest news

25th March 2025

Reduce sound transference with West Fraser CaberAcoustic

CaberAcoustic from West Fraser is a highly versatile, effective and economical sound-reducing flooring solution. Reducing both impact and airborne transmitted sounds, it can be laid over concrete and timber floors in both new and existing buildings.

Posted in Acoustics, Noise & Vibration Control, Articles, Building Industry News, Building Products & Structures, Building Services, Building Systems, Facility Management & Building Services, Floors, Interior Design & Construction, Interiors, Posts, Restoration & Refurbishment, Retrofit & Renovation, Timber Buildings and Timber Products

25th March 2025

Vent-Axia Kicks Off Charity Football Tournament in Support of Cancer Research UK

Ventilation leader Vent-Axia brought together leading building design professionals for an action-packed Charity Powerleague 5-a-side Football Tournament on Thursday 20th March in Shoreditch, London, in aid of Cancer Research UK.

Posted in Air Conditioning, Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Charity work, Facility Management & Building Services, Heating, Ventilation and Air Conditioning - HVAC

25th March 2025

Jane Elvins bolsters GEZE UK Specification team

GEZE UK, a leading manufacturer and provider of door, window and access control systems, is delighted to welcome Jane Elvins, who joins as Specification and Business Development Manager.

Posted in Access Control & Door Entry Systems, Architectural Ironmongery, Articles, Building Industry News, Building Products & Structures, Building Services, Doors, Facility Management & Building Services, Recruitment, Retrofit & Renovation, Security and Fire Protection, Windows

24th March 2025

Putting Glidevale Protect in the frame at InverTay Homes development

Leading building products manufacturer Glidevale Protect is supplying its construction and roofing membranes for a new timber frame housing development currently being constructed by InverTay Homes in Dundee.

Posted in Articles, Building Industry News, Building Products & Structures, Building Services, Building Systems, Case Studies, Facility Management & Building Services, Membranes, Restoration & Refurbishment, Retrofit & Renovation, Roofs, Sustainability & Energy Efficiency, Timber Buildings and Timber Products, Walls

Sign up:

Sign up: