Tackling modern day slavery in the supply chain

Danny Hobson, Ethical and Quality Improvement Manager at Arco, discusses the surprising prevalence of modern day slavery in the supply chain and how the company hopes its own robust approach to ethical supply can inspire others to make a difference.

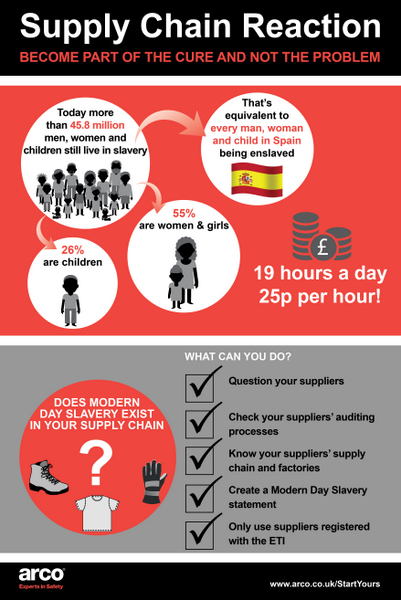

Ethical supply chain reaction: become part of the cure not the problem

Tamil Nadu is the powerhouse of India’s textile industry and accounts for 20% of the country’s total export of ready-made garments. Housing 58% of India’s textile mills, Tamil Nadu employs over 1.02 million workers in the garment sector, most of whom are subject to severe labour exploitation and dangerous conditions. As the world’s second largest textile exporter, India’s garments find their way into supply chains around the globe, including the UK.

Tamil Nadu is just one example of the international crime of modern day slavery. The workforce is predominantly female and many are regular victims of bonded labour. The women millworkers experience many forms of ill treatment, including excessive working hours, poor living conditions in hostels and illness caused by exposure to cotton dust. Withholding wages and paying below minimum wage is common practice, while workers have no access to grievance mechanisms.

Tamil Nadu is just one example of the international crime of modern day slavery. The workforce is predominantly female and many are regular victims of bonded labour. The women millworkers experience many forms of ill treatment, including excessive working hours, poor living conditions in hostels and illness caused by exposure to cotton dust. Withholding wages and paying below minimum wage is common practice, while workers have no access to grievance mechanisms.

The figures make startling reading but unfortunately it is still too easy for companies and consumers to turn a blind eye. Many consumers are unaware of the conditions under which the goods they buy have been produced and even when businesses have good intentions, auditing a supply chain with multiple suppliers can be so complex, confidently identifying and eliminating the use of slave labour can present a serious challenge. The recent Panorama programme which discovered Syrian refugees working illegally in Turkey for major brands many of whom were proponents of ethical trading, is a case in point. The fact that slave labour has been found so readily within the supply chains of companies who are proactive in trying to outlaw this kind of practice shows just how inherent the problem is and how much work there is to be done.

Thankfully there is increasing pressure for businesses to face up to their responsibilities from both a moral and legal perspective. The Modern Slavery Act, which was introduced in 2015 to consolidate laws covering the issue of slavery in the UK, now also includes provisions for supply chains. The Transparency in Supply Chain Provisions require businesses which have an annual turnover above £36 million to publish a statement which confirms the steps taken to mitigate the risk that slavery and human trafficking are in their business or supply chain.

At Arco, our ethical supply policy means we are committed to making a difference. As well as meeting our obligations in line with these provisions, Arco is leading the way in promoting ethical trade within the supply of safety products. In the same way as we have taken the lead in driving improvements in quality standards across our industry, through investment in product testing and assurance, Arco is also taking action to raise standards throughout our supply chain when it comes to ethical trading; we call it starting a supply chain reaction.

Arco’s drive to continually improve ethical trading standards within our business is underpinned by our membership of the Ethical Trading Initiative (ETI), a leading alliance of companies, trade unions and NGOs that promotes respect for workers’ rights around the globe. The ETI’s aim is to improve the lives of workers by eradicating exploitation and discrimination. Arco joined the ETI in 2007 and remains the first and only safety distributor to be a member.

Supplier Ethical Compliance

Arco has created a process to ensure the ethical compliance and capabilities of all suppliers manufacturing products which carry an Arco brand. This is in line with the ETI Base Code which is founded on the conventions of the International Labour Organisation (ILO) and is an internationally recognised code of labour practice. Before any products are made, suppliers must commit to Arco’s Ethical Compliance Procedure which ensures they have the capability and systems to meet the requirements of the ETI Base Code. When a supplier wishes to use subcontractors or outworkers for Arco production then this must be approved in advance by Arco. It is the supplier’s obligation to provide evidence that any subcontractor or outworker used conforms to the standards outlined in the ‘Ethical Guide for Vendors’ document.

Ethical Auditing

Manufacturers of Arco own label products are appraised using a risk based approach. Factory assessments are conducted by one of the world leading social compliance audit companies or by Arco employees who have been trained by the ETI in the application of the ETI Base Code. Factories are assessed for Ethical compliance and corrective plans agreed to resolve breeches of national and local laws and the ETI base code. The corrective action plans are managed by the Arco Product Assurance Team, Arco Xiamen team (based in China) and the manufacturer themselves.

In the first instance it is always preferable to try and help a supplier raise their standards. As well as improving working conditions for staff, this can benefit the supplier by helping them to win more contracts and compete more effectively for international business. Examples of how Arco has helped its suppliers improve employee wellbeing include helping them to provide better dining and hygiene facilities and instigating training programmes to improve employee morale and engagement. Any supplier failing seriously or consistently to adhere to the standards detailed in the ‘Ethical Guide for Vendors’ document will be removed from the approved supplier list.

What Can You Do?

If you are concerned about unethical practices or slave labour in your supply chain there are a number of steps you can take:

- Ask your suppliers about their supply chain and the factories providing your goods.

- Ask your suppliers about their ethical assurance measures and due diligence processes.

- If your supplier has a turnover in the UK greater than £36m and falls under the Modern Slavery Act, review their published statement.

- Be sure about your own supply chain by using suppliers that are members of the Ethical Trading Initiative or equivalent organisations.

The task of auditing a complex supply chain with multiple suppliers can be arduous. By ensuring you only work with ethical suppliers such as Arco, this task is simplified. The measures we take and the assurance we offer to our customers, backed by our membership of the Ethical Trading Initiative, mean peace of mind for procurement teams.

Box out: ETI nine point base code

- Employment is freely chosen

- Freedom of association and the right to collective bargaining are respected

- Working conditions are safe and hygienic

- Child labour shall not be used

- Living wages are paid

- Working hours are not excessive

- No discrimination is practiced

- Regular employment is provided

- No harsh or inhumane treatment is allowed

Resources

The 36 million people bound by Modern Day Slavery cannot all speak for themselves, so Arco has created a short film on their behalf. Meet Tuan and find out how you too can begin to make a difference.

Latest news

17th April 2025

Nuaire shares expertise at Specifi Mechanical Services events in 2025

Indoor air quality and ventilation manufacturing specialist Nuaire is pleased to be exhibiting at the Specifi Mechanical Services events once again in 2025.

Posted in Air Conditioning, Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Exhibitions and Conferences, Facility Management & Building Services, Heating, Ventilation and Air Conditioning - HVAC, Restoration & Refurbishment, Retrofit & Renovation

15th April 2025

West Fraser: CaberDek earns top marks from Home Counties carpentry specialist

A specialist carpentry sub-contractor covering housing sites across a large swathe of the Home Counties has come to value CaberDek from the West Fraser range for a variety of reasons: not least because the high quality panel product doesn’t destroy his operatives’ electric saws!

Posted in Articles, Building Industry News, Building Products & Structures, Building Systems, Case Studies, Restoration & Refurbishment, Retrofit & Renovation, Roofs, Timber Buildings and Timber Products, Wooden products

15th April 2025

GEZE: The Role of Access Control Systems in Enhancing Building Safety

Jane Elvins, Specification and Business Development Manager at GEZE UK, delves into the role of access control systems in enhancing building safety…

Posted in Access Control & Door Entry Systems, Architectural Ironmongery, Articles, Building Industry News, Building Products & Structures, Building Services, Doors, Facility Management & Building Services, Health & Safety, Restoration & Refurbishment, Retrofit & Renovation, Security and Fire Protection

11th April 2025

Don’t Do a Dave! It’s Time to Lock FIT Show 2025 in Your Calendar!

It’s that time again – FIT Show is back! You could be forgiven for thinking there won’t be much new to see when FIT Show returns to the NEC from 29 April – 1 May. Wrong!

Posted in Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Continuing Professional Development (CPD's), Exhibitions and Conferences, Information Technology, Innovations & New Products, Restoration & Refurbishment, Retrofit & Renovation, Seminars, Training

Sign up:

Sign up: