The evolution of fixings

Traditional fixing methods such as screws, glue and pins have improved significantly over the centuries – however, modern interior applications demand more sophisticated solutions, with innovation being the key. Here, Julie Freedman, Head of Sales and Marketing at Buttonfix explores the evolution of fixings and modern fastening alternatives.

There’s plenty of debate regarding where the first fixings and screws originated. According to bolt expert Bill Eccles’, their history dates back as far as 287 – 212 BC, when Archimedes developed the screw principle to construct devices to raise water, and there are signs that the Egyptians used screws even before this time, using wooden equivalents to remove bilge water from ships.

However, it has been agreed amongst experts that the use of the screw as a fastener has existed for approximately 400 years, and that it was the Industrial Revolution that sped up the development of nuts, bolts and screws, with each item becoming an essential component of the construction industry.

screw as a fastener has existed for approximately 400 years, and that it was the Industrial Revolution that sped up the development of nuts, bolts and screws, with each item becoming an essential component of the construction industry.

Reviewing the extensive history of the screw as a fastener, it is clear that construction has relied on this tool for every day use for centuries. However, trends in interior design mean that using screws as a universal solution for fixings and fastenings is no longer the only solution.

Where screws were the immediate go-to for securing panelling and decorative items, they now face the challenges of increasingly complex and demanding interior applications.

Architects often use panelling in interior design to achieve a unique finish, utilising panels whilst decorating walls or hiding unsightly features such as washroom pipework. However, the installation of these panels can be a time-consuming task for the contractor.

When an architect specifies a wall consisting of several panels, the panels have to be aligned exactly to the drawing specification in order to achieve the desired look as even the slightest misplacement can disrupt the design of a room. Therefore, it is an arduous task of making the measurements on-site, cross-referencing the specifications before positioning the panels and having someone hold them in place whilst another fitter screws them in.

Alongside this, there is also the risk that the screws can damage the panels when being fixed; leaving unsightly marks that will spoil the aesthetic integrity of the design. There are also some panels that cannot be easily drilled, such as those incorporating glass or metal.

The obvious alternative to screws would be glue. Like screws, glue has its own history and unique place within modern interior design and fittings sectors.

The earliest available evidence of glue dates back over 5,000 years, when glue like materials were mixed with pigments on ancient cave paintings presumably to stabilise and protect them from moisture damage.

Glues made predominantly from animal derived materials have been attributed back to the days of the Ancient Egyptians, as illustrated by a casket made from wood and glue discovered in King Tutankhamun’s tomb. Cement like glue was also used by the Romans in order to adhere mosaics to floors and walls.

Mosaics and tiles aside, what worked for the Romans does not usually work for the modern interior since gluing wall panels in place, can be messy and will be permanent. So, if the panels needed to be removed for any reason (such as accessing electrical or plumbing works behind the wall), this will cause damage to the panels and walls, often resulting in costly and time consuming repairs.

These contemporary architectural issues can be time consuming and problematic; however there is a solution.

Innovative fixing products have developed, driven by the demand from architects and installers for hidden, easy-to-use and removable fastening methods.

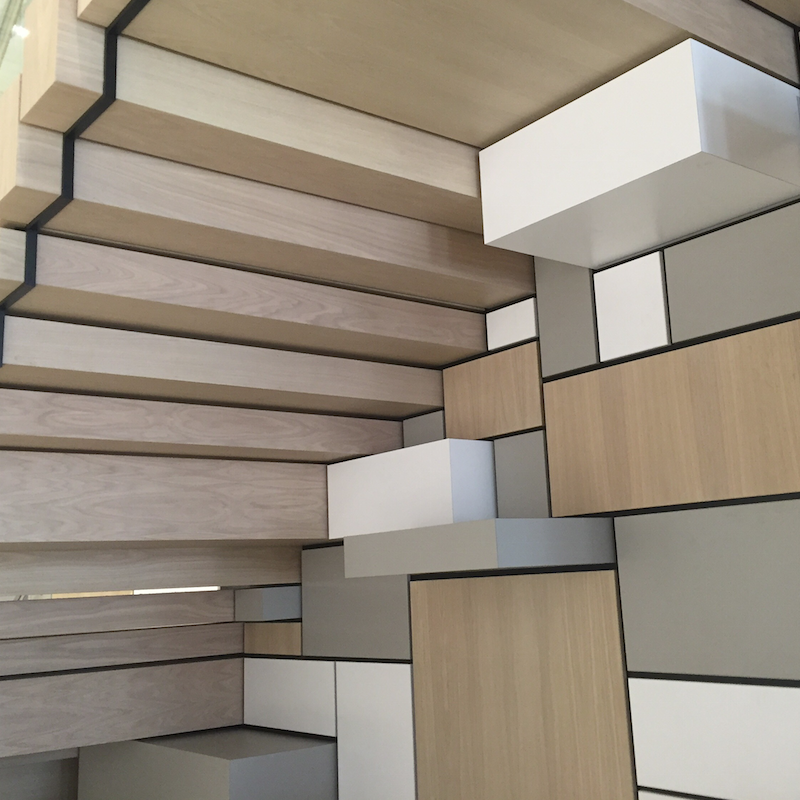

For example, Andy Clarke Woodwork Design Manufacture and Installation Ltd has utilised the flexibility and timesaving benefits of a modern fixing solution to install a bespoke feature wall in a leading home department store.

For example, Andy Clarke Woodwork Design Manufacture and Installation Ltd has utilised the flexibility and timesaving benefits of a modern fixing solution to install a bespoke feature wall in a leading home department store.

The 3D panelled feature wall was built off site in segments. With a stringent installation schedule in place, Andy sought an alternative fastening solution to screws and adhesive that would reduce time onsite whilst ensuring accuracy.

Requiring a flush finish for the full effect, Andy specified a fixing which allowed for panel to panel contact and offered an invisible fastening solution with the added benefit that the panels could easily be removed if necessary.

Arriving to site with the fastener components pre-fitted, the two-man installation team easily and quickly installed the large feature wall in less than five weeks, knowing the panels were secure by the audible ‘click’ of the fixes connecting to the wall.

Saving essential time onsite without compromising the aesthetic appearance or quality of the installation where accuracy is of paramount importance, a modern fastening alternative presented the ideal solution.

Screws and glue, of course, have their place in the architectural world – without their invention and years of development, the construction industry would be a significantly different place. However, innovation is crucial for the current needs of the digital design arena. Invisible fasteners provide a modern solution for today’s designers and drive innovation in the sector forward.

Latest news

8th April 2025

Digital Construction Week 2025 announces first wave of industry-leading speakers

Digital Construction Week (DCW), the UK’s premier event for digital innovation in the built environment, is set to return to ExCeL London on 4 – 5 June 2025.

Posted in Articles, BIM, Infrastructure & CAD Software, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Building Systems, Civil Engineering, Exhibitions and Conferences, Hard Landscaping & Walkways, Health & Safety, Information Technology, Innovations & New Products, Landscaping, Retrofit & Renovation, Seminars

7th April 2025

Abloy UK provides bespoke access control solution for CPA Group’s Lanarkshire HQ

Abloy UK has supplied CPA Group with its PROTEC2 CLIQ solution to streamline access control and protect assets at its headquarters in Shotts, Lanarkshire.

Posted in Access Control & Door Entry Systems, Architectural Ironmongery, Articles, Building Industry News, Building Products & Structures, Building Services, Case Studies, Doors, Facility Management & Building Services, Health & Safety, Restoration & Refurbishment, Retrofit & Renovation, Security and Fire Protection

7th April 2025

ASSA ABLOY EMEIA: A new generation of reader is added to the Aperio digital access family

There is now a way to control access digitally, effectively and wire-free, thanks to ASSA ABLOY EMEIA…

Posted in Access Control & Door Entry Systems, Architectural Ironmongery, Articles, Building Industry News, Building Products & Structures, Building Services, Doors, Facility Management & Building Services, Health & Safety, Information Technology, Innovations & New Products, Posts, Retrofit & Renovation, Security and Fire Protection

7th April 2025

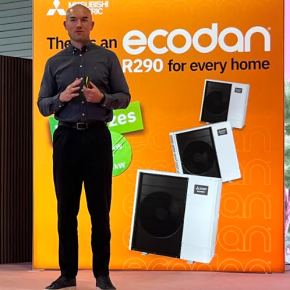

Mitsubishi Electric unveils growing Ecodan R290 Heat Pump Range

Mitsubishi Electric is proud to announce the expansion of its highly efficient and environmentally friendly Ecodan R290 heat pump range.

Posted in Articles, Building Industry News, Building Products & Structures, Building Services, Facility Management & Building Services, Heating Systems, Controls and Management, Heating, Ventilation and Air Conditioning - HVAC, Information Technology, Innovations & New Products, Pipes, Pipes & Fittings, Plumbing, Restoration & Refurbishment, Retrofit & Renovation, Sustainability & Energy Efficiency

Sign up:

Sign up: