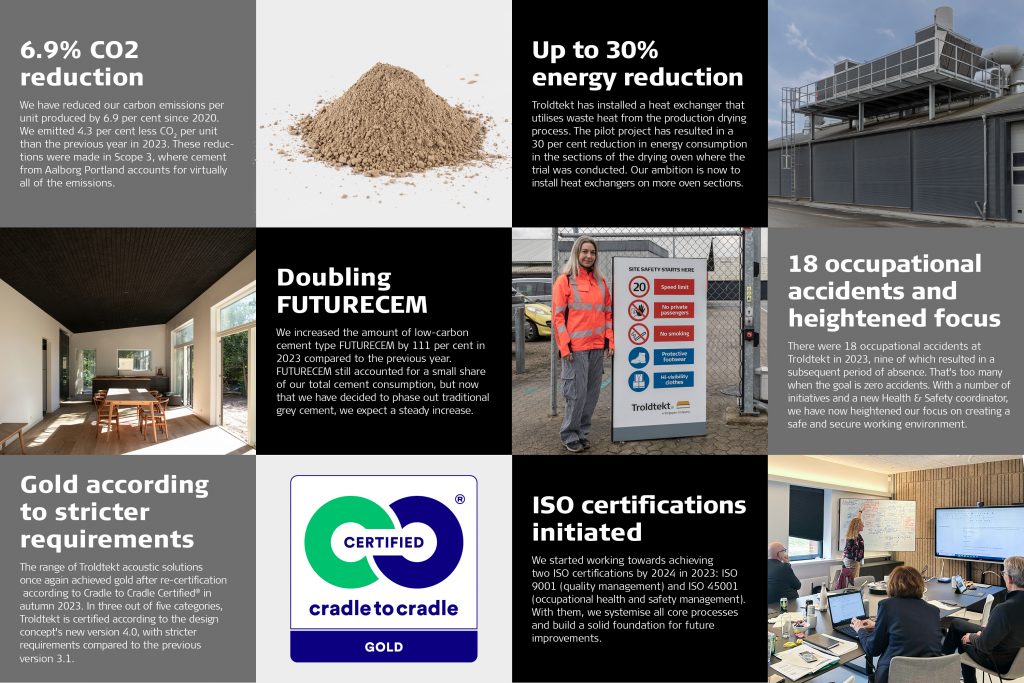

In three years, Troldtekt has reduced its carbon footprint per square metre of acoustic panels produced by 6.9%. This is shown by data in Troldtekt’s CSR report for 2023. The reduction has occurred in scope 3, which mainly covers cement from Aalborg Portland. Part of the explanation is due to the cement type FUTURECEM™.

Cement provides the well-known Troldtekt® acoustic panels with their robustness, fire retardant properties and extensive durability. But the cement from Aalborg Portland also accounts for virtually the entire carbon footprint of the panels. In 2023, Troldtekt reduced its carbon footprint per square metre of acoustic panel produced by 4.3%. Over three years – from 2020 to 2023 – the reduction has been 6.9%.

The new CO2 figures are included in Troldtekt’s CSR report for 2023. It shows that 99% of the carbon footprint in 2023 came from the so-called scope 3, which primarily covers the purchase of cement. At Troldtekt’s own factory (scope 1 and 2), 94.5% of energy consumption in 2023 came from renewable sources in the form of biofuel and wind power. This figure was slightly lower than in previous years due to a period of maintenance on the biomass boiler.

Tina Snedker Kristensen, Head of Sustainability and Communications at Troldtekt A/S, comments: “Reducing CO2 is one of the most important focus areas in construction. Over a number of years, we have approached 100% renewable energy in our own factory, and now we have also started reductions for scope 3, which is more difficult. Our ambition is to continue to reduce significantly as we roll out new types of cement in our production.”

FUTURECEM makes a difference

In 2023, Troldtekt doubled the share of acoustic panels produced based on the cement type FUTURECEM. Together with other reductions at Aalborg Portland, this is a significant part of the explanation for the decrease in the carbon footprint. FUTURECEM utilises the synergies between calcined clay and lime filler, making it possible to replace a large part of the burnt clinker in the cement.

Over the entire product life cycle, the carbon footprint of Troldtekt acoustic panels based on FUTURECEM is:

– 26% lower than that of Troldtekt panels based on grey cement

– 38% lower than that of Troldtekt panels based on white cement.

Tina continues: “In 2023, acoustic panels based on FUTURECEM accounted for approximately twice as much of our production as in 2022. This meant that the amount of FUTURECEM was almost on a par with the amount of traditional grey cement. The share of FUTURECEM will continue to increase significantly when we completely phase out the panels based on traditional grey cement from 2024.”

She adds that Troldtekt is also gradually starting to replace white cement with FUTURECEM in the many panels, which are painted in white and other light colours.

Gold certification, energy savings and launch of ISO work

Our carbon footprint reduction and the doubling of acoustic panels based on FUTURECEM are two of the highlights in the CSR report for 2023. Here are three more:

> The range of Troldtekt acoustic solutions in natural wood and the standard colours grey, white, clay and black once again achieved gold after re-certification according to Cradle to Cradle Certified® in autumn 2023. In three out of five categories, Troldtekt is certified according to the concept’s version 4.0, where the requirements are stricter. These are Material Health, Renewable Energy and Carbon Management and Water & Soil Stewardship. In Material Reutilisation and Social Fairness, Troldtekt will be certified according to version 4.0 in 2025.

> Troldtekt has installed a heat exchanger that utilises waste heat from the production drying process. The pilot project has resulted in a 30% reduction in energy consumption in the sections of the drying oven where the trial was conducted. Our ambition is now to install heat exchangers on more oven sections in production.

> In 2023, Troldtekt started working towards achieving two ISO certifications by 2024: ISO 9001 (quality management) and ISO 45001 (occupational health and safety management). They systemise all core processes and build a solid foundation for future improvements.

Mitigating problems

Troldtekt wood wool acoustic panels excel at mitigating the problems stemming from long reverberation time and reflected sound. They are available in a variety of different structures and colours, combining superior sound absorption with an award-winning design. The Troldtekt range has a minimum expected life cycle of 50 years coupled with excellent resistance to humidity and tested to meet ball impact standards. The range is available in various sizes and structures, from extreme fine to fine. They can be supplied as unpainted natural wood or natural grey Futurecem®, alternatively they can be finished in our standard colours or almost any RAL or NCS upon request.

Depending on the panel specified, reaction to fire is classed in accordance with EN 13501 as B-s1,d0 or A2-s1,d0 respectively. Cradle to Cradle Certified® at Gold level, Troldtekt wood wool acoustic panels are manufactured using wood from certified forests (PEFC™ and FSC®C115450) and can contribute positively to a building’s BREEAM, WELL or LEED points.

Samples, case studies and technical guidance are available from www.troldtekt.co.uk or see the company’s product listings on NBS or Material Bank.